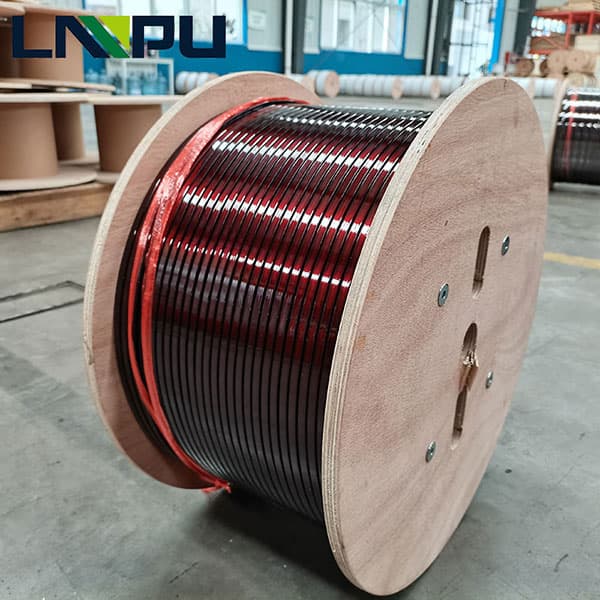

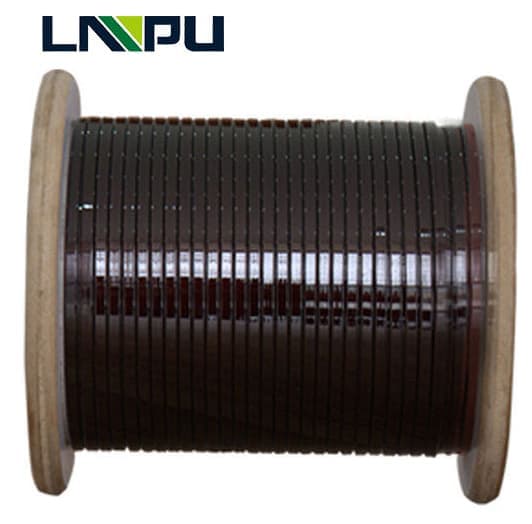

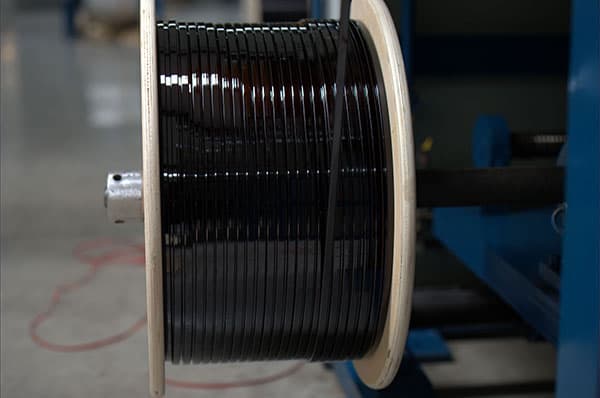

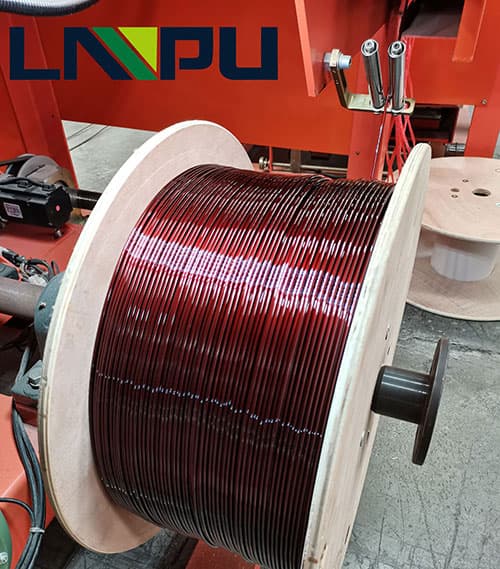

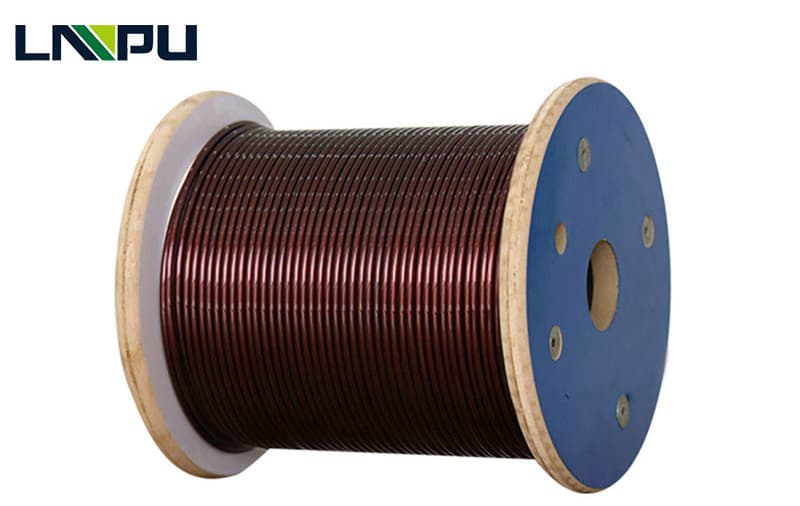

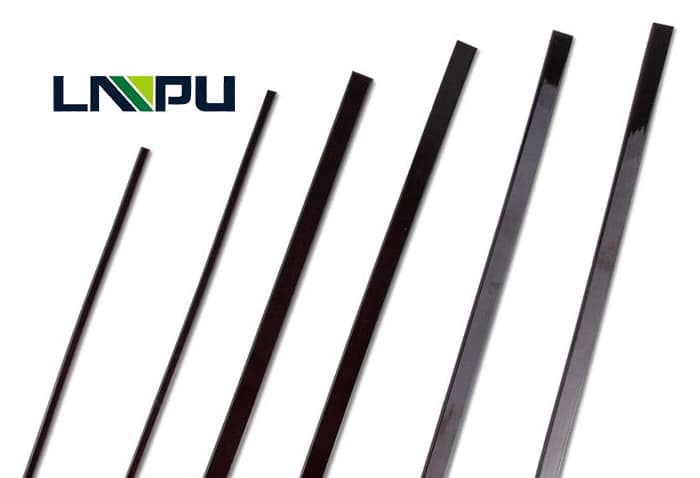

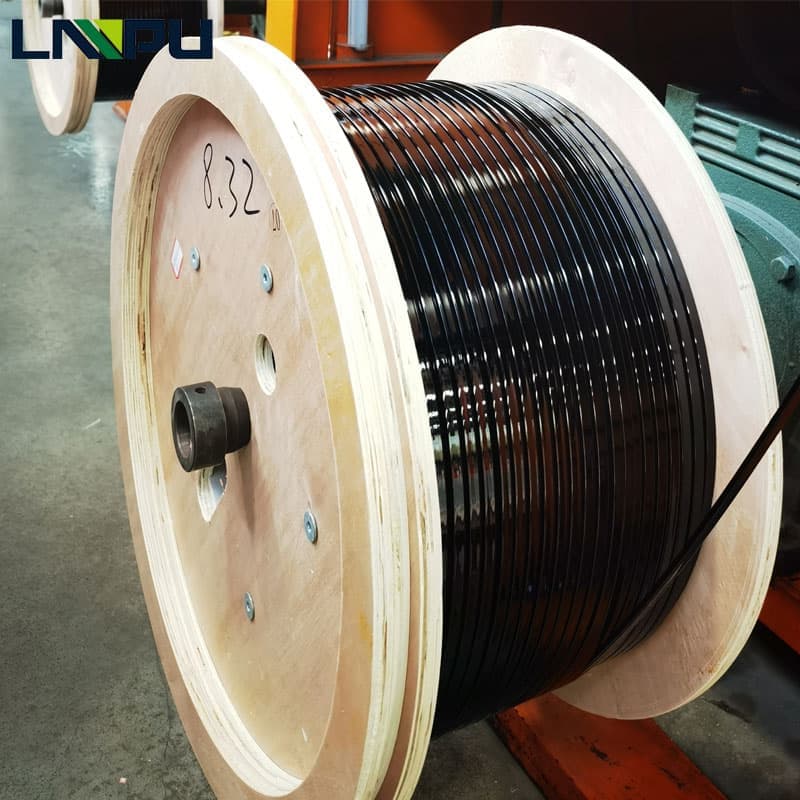

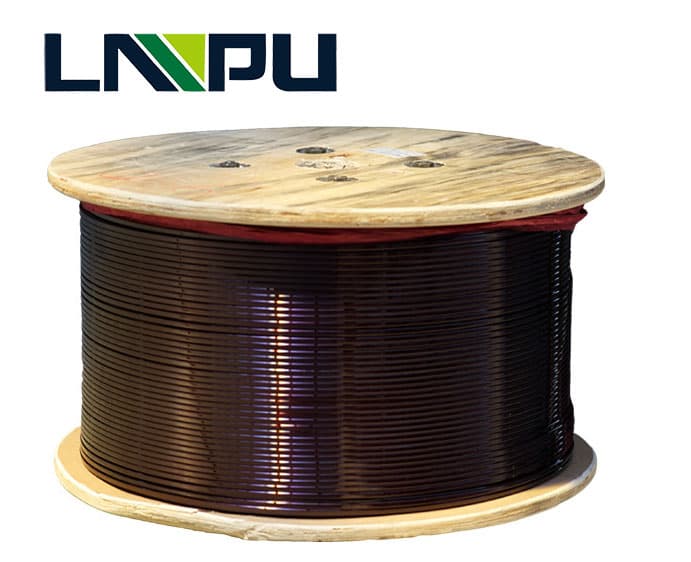

High Breakdown voltage Shaped Aluminum Wire Enameled

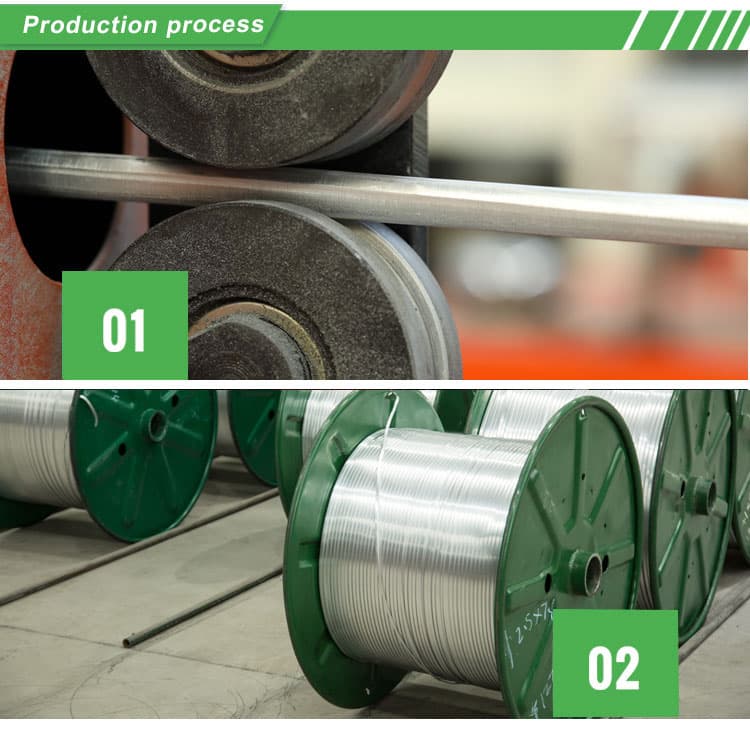

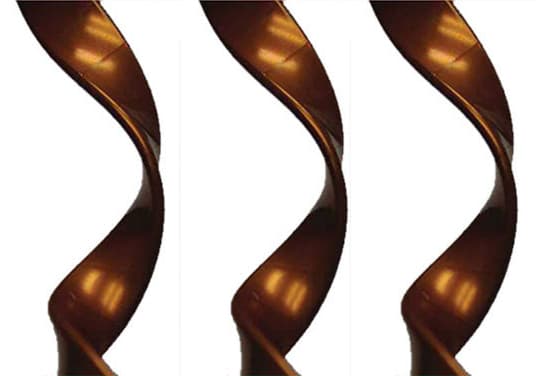

The High Breakdown voltage Shaped Aluminum Wire Enameled includes a conductor and a radiation protection layer, the conductor is coated with an insulating layer, the insulating layer is wrapped with a polymethylpentene film, and the polymethylpentene film is wrapped with a corrosion-resistant layer. The anti-corrosion layer is wrapped with an anti-radiation layer, the anti-radiation layer is wrapped with an epoxy-modified silicone resin layer, and the epoxy-modified silicone resin layer is wrapped with an outer layer.

Product name: UEF1/U ,UEWH/U

GB name: QA/155, QA/180

Heat resistance grade: 155¡æ, 180¡æ

Specification range: 0.04-1.6mm

Characteristics of High Breakdown voltage Shaped Aluminum Wire Enameled:

High Breakdown voltage Shaped Aluminum Wire Enameled has excellent insulation, avoids local breakdown, has good heat resistance and strong corrosion resistance during use, can improve the safety and service life of the motor, and can also isolate the magnetic field radiation. The radiation damage to the outside world and the human body is reduced, thereby effectively improving the environmental protection of the electromagnetic wire.

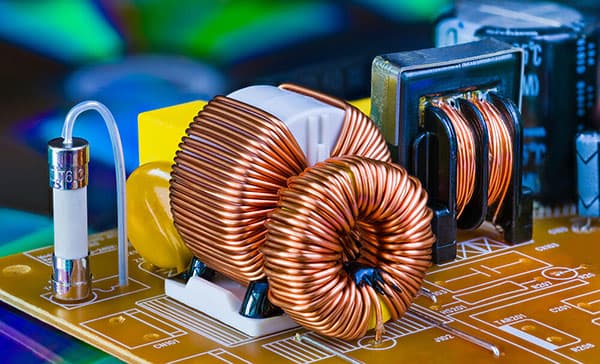

Application of High Breakdown voltage Shaped Aluminum Wire Enameled:

High Breakdown voltage Shaped Aluminum Wire Enameled can be used as direct-weldable high-temperature resistant equipment