Home » magnet wire » fiberglass covered wire

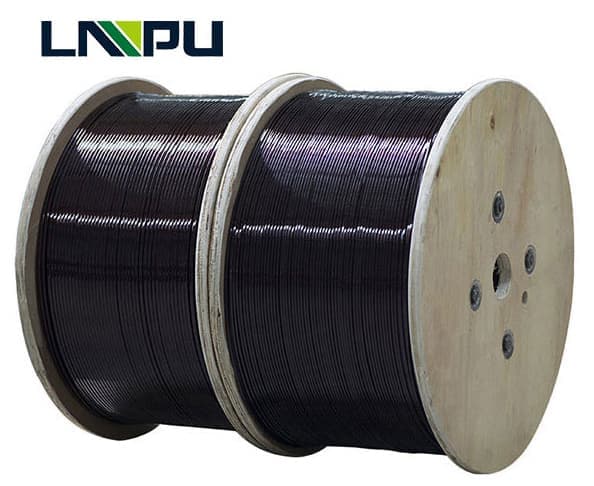

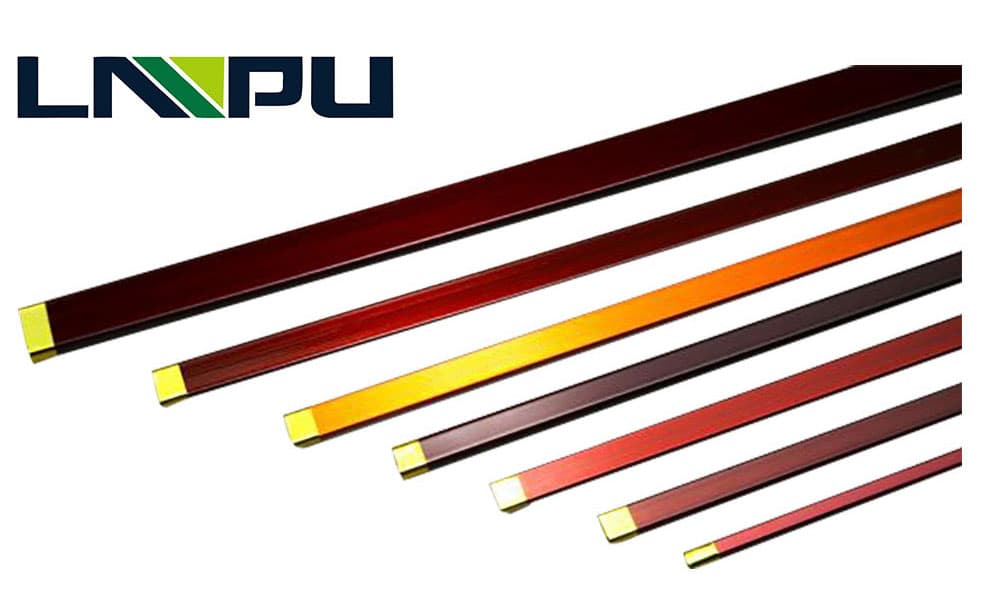

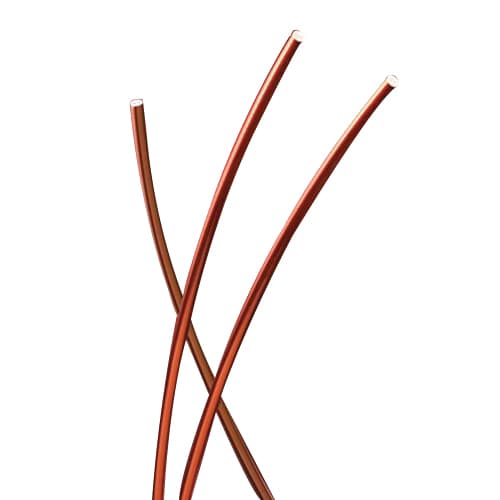

fiberglass covered wire

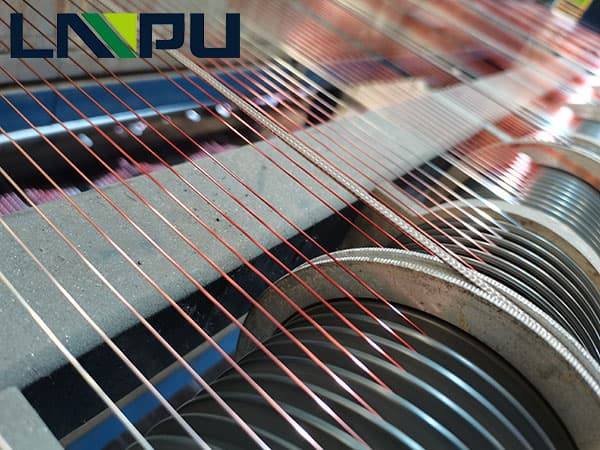

The main advantages of fiberglass covered wire are:

1. The quality factor Q value is large;

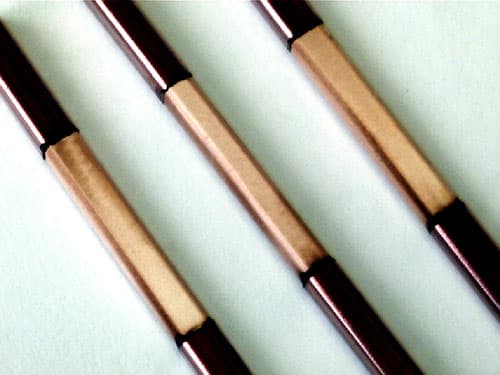

2. Because it is twisted by multiple enameled wire bundles, it has good flexibility and can reduce the skin effect;

3. Because it is composed of polyurethane enameled wire, the dielectric loss angle is small, and it has direct solderability.

The disadvantage is: poor moisture resistance.

Contact US

Get Price

Share:

Content

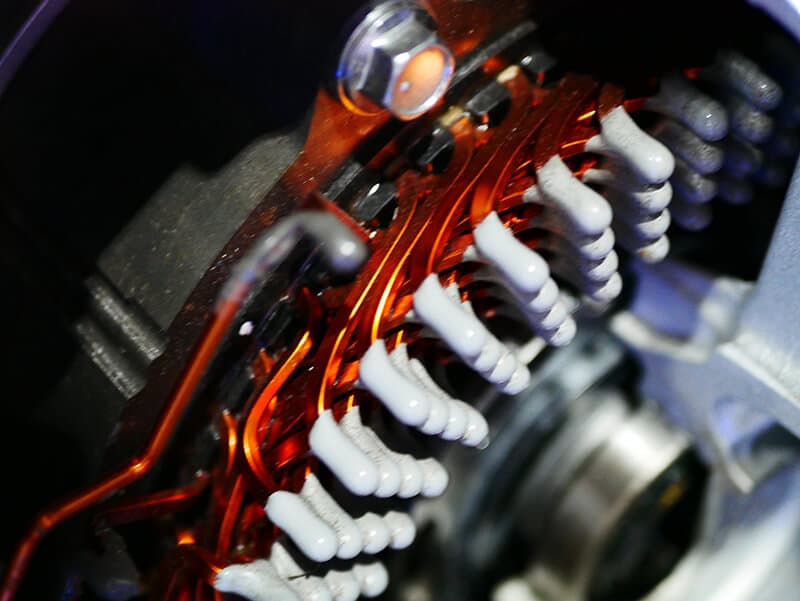

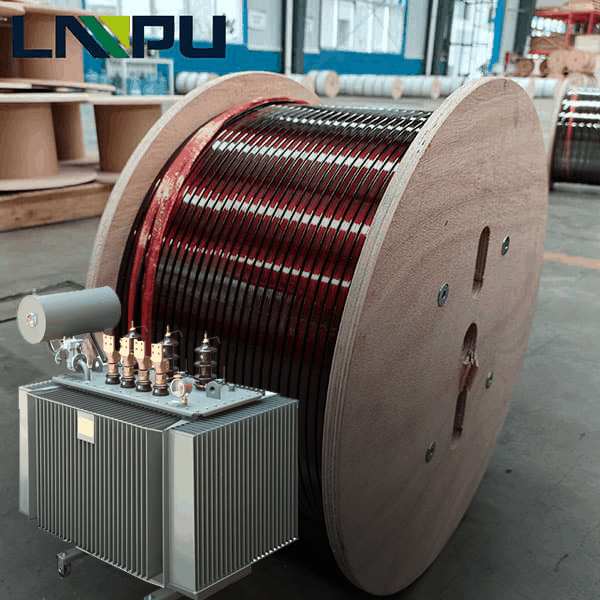

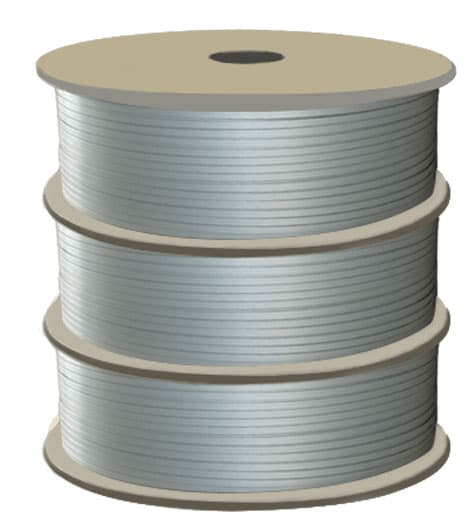

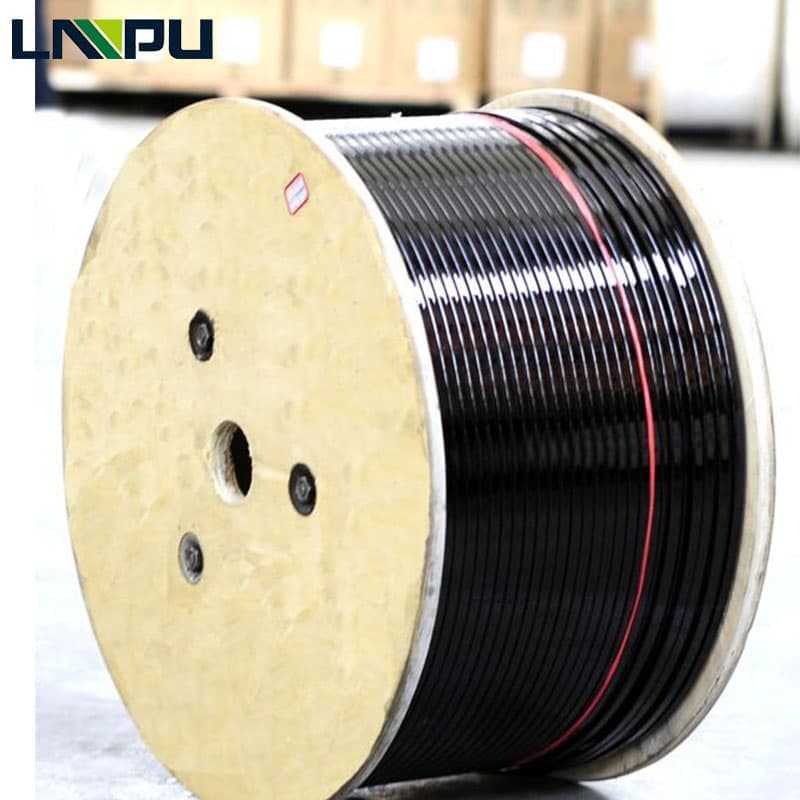

fiberglass-covered wire is mainly used for coils of electronic instruments and electrical equipment under various frequencies and winding wires for intermediate frequency and variable frequency motors.

Inquiry

More magnet wire