Fiberglass Covered Aluminum Wire Production Proce

Fiberglass Covered Aluminum Wire Production Proce

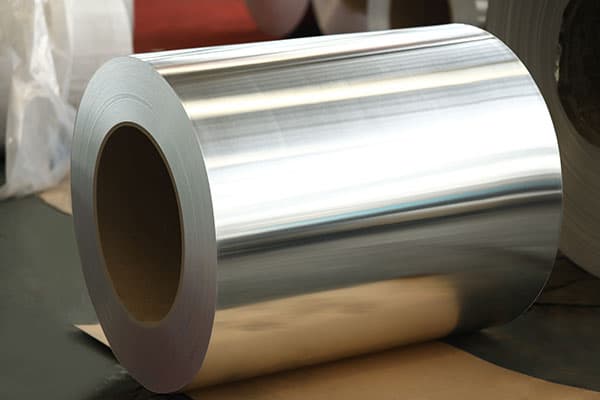

One step :

Take the pure aluminum material drawing into the aluminium rod wire;

Two step :

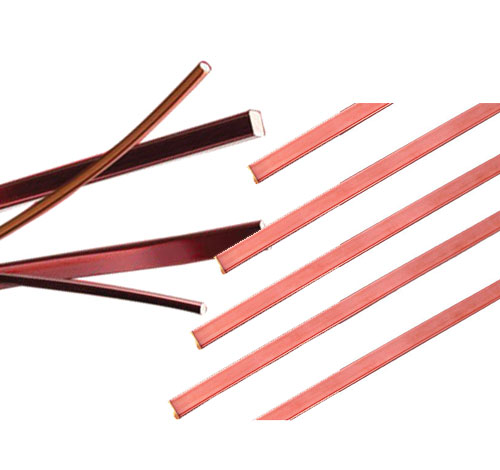

Through the extrusion production line, take the aluminum rod wire into extruding and coarse drawing operation, then becoming the requirement specification of Bare aluminium wire;

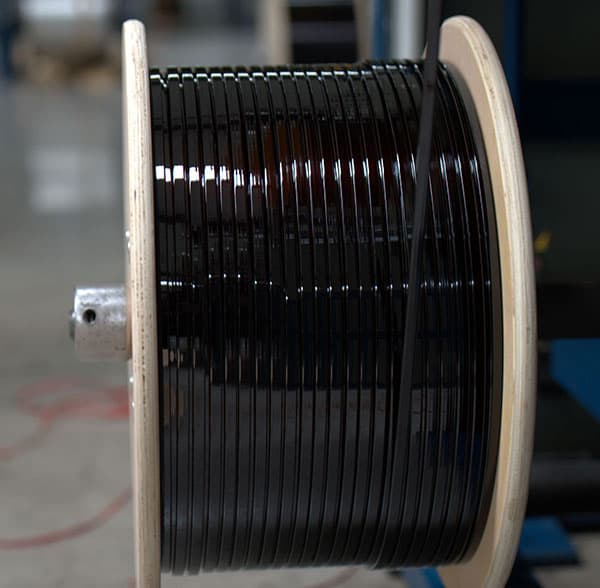

Three step :

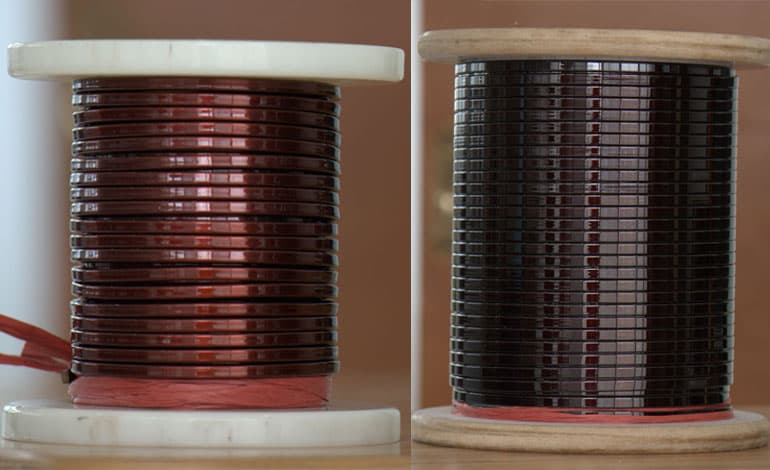

Take up the Bare aluminum wire conductor, and inspection the bare wire coil products;

Four step :

Annealing the bare aluminum wire, and placed neatly, ready to production;

Five step :

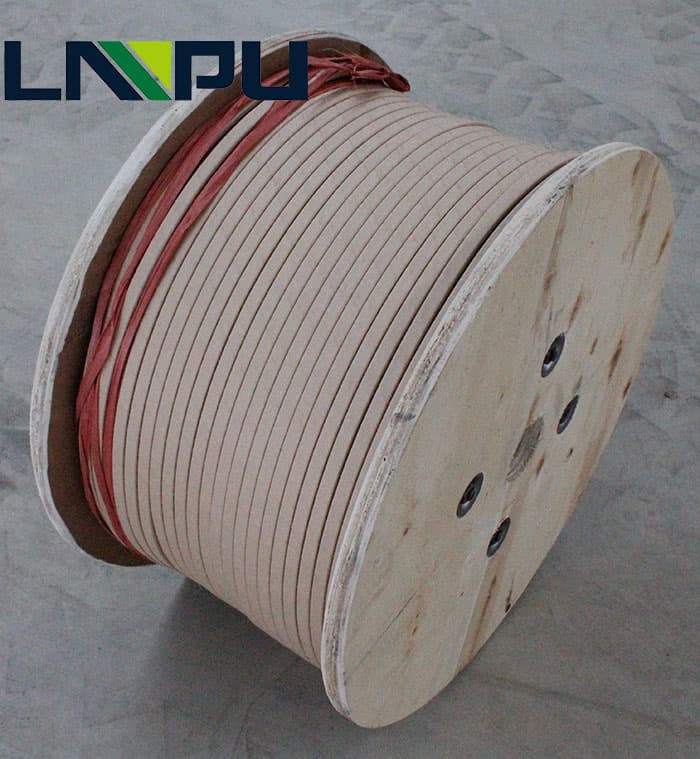

Pay-off the wire coil products, ready to fiber glass covering production;

Six step :

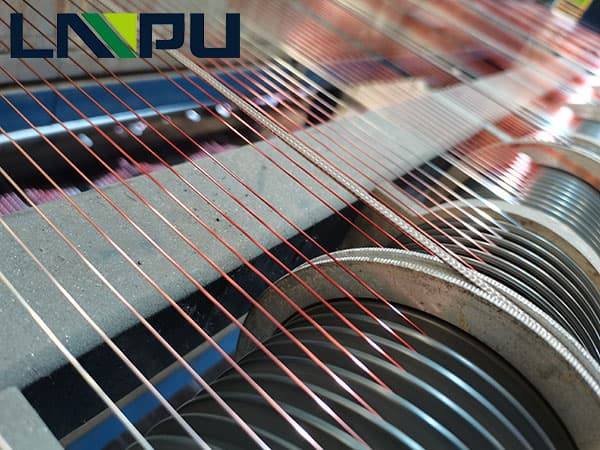

Taking into straightening and tension levelling operation, and then for the covering fiber glass;

Seven step :

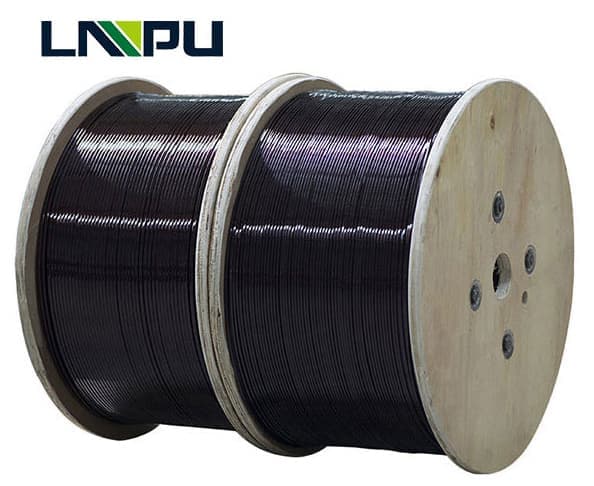

Doing the fiber-glass covering operation, and inspecion the production process;

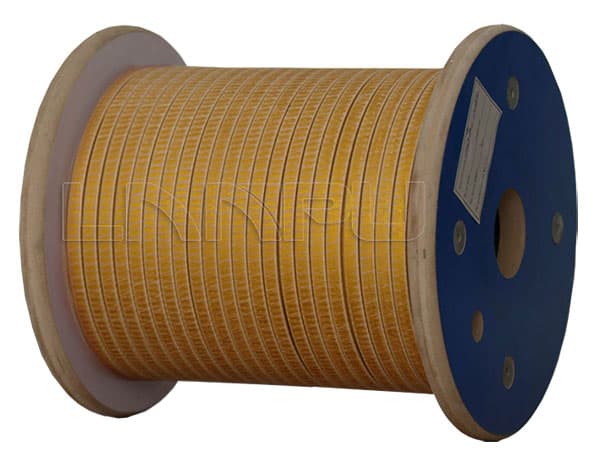

Eight step :

Packing the fiberglass covered wire products, and placed neatly in the warehouse.

Oil-immersed transformer windings, medium and large electrical motor and power substations, etc. Glass-fiber covered aluminum magnet wire used to have weak coating strength (abrasion resistance, shock resistance, and flexibility).