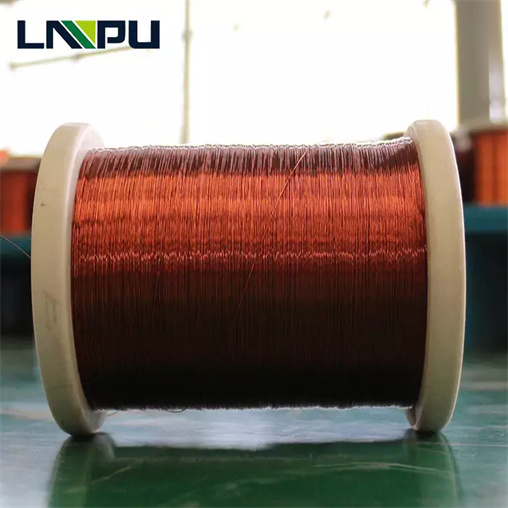

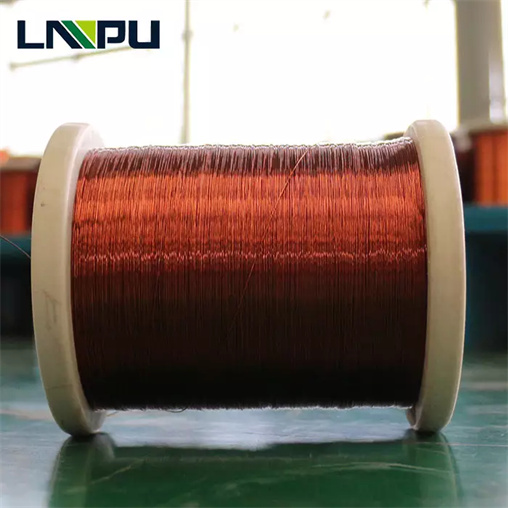

Features Of Round Enameled Aluminum Wire

Features Of Round Enameled Aluminum Wire uses them in lighting, ceiling fans, computer cases, and even some mobile phones.

It also requires less maintenance because it will not become very brittle after a period of time.

One of the most attractive metals on the market today is enameled metal. They are very affordable compared to other types of wires, and they have many advantages compared to other types of wires.

Advantages of enamel alloys: Compared with copper alloys, enamel aluminum alloys are easier to wire, and there is almost no detectable oxide layer on the surface of the enamel aluminum alloy, making it a very strong insulator with longer insulation. Lasting life. It also offers a variety of colors from light white to bright red. Aluminum is also easy to alloy and weld, so you can easily create different shapes and designs. For aluminum alloys, the surface area is much larger than copper alloys.

Advantages of aluminum alloy: aluminum alloy has more applications. You can use them in lighting, ceiling fans, computer cases, and even some mobile phones.

Advantages of copper alloy: The material can be easily processed and offers a variety of colors. When adding solder, you can use copper to create complex patterns and designs. However, these patterns are not so persistent. Copper alloy wire is more durable and has a longer service life.

One advantage of Round Enameled Aluminum Wire is that they are generally cheaper than copper alloy wires and require less maintenance. After a period of time, the copper wire may become brittle, causing solder corrosion.

The disadvantage of aluminum alloy wire is that the surface is degummed and becomes brittle after a period of time. This makes the wire difficult to use and much more expensive than other wires.

On the other hand, wires made of steel wires are stronger and have fewer maintenance requirements. It is also available in a variety of colors and has a high degree of flexibility.

Therefore, when you compare these two wire types, it is obvious that if you want to buy aluminum that is easy to process, welded, and processed into various shapes, aluminum is the better choice. On the other hand, copper wire performs the same task but is much more expensive.

It also requires less maintenance because it will not become very brittle after a period of time. This is one of the reasons why wires are much cheaper than copper wires.