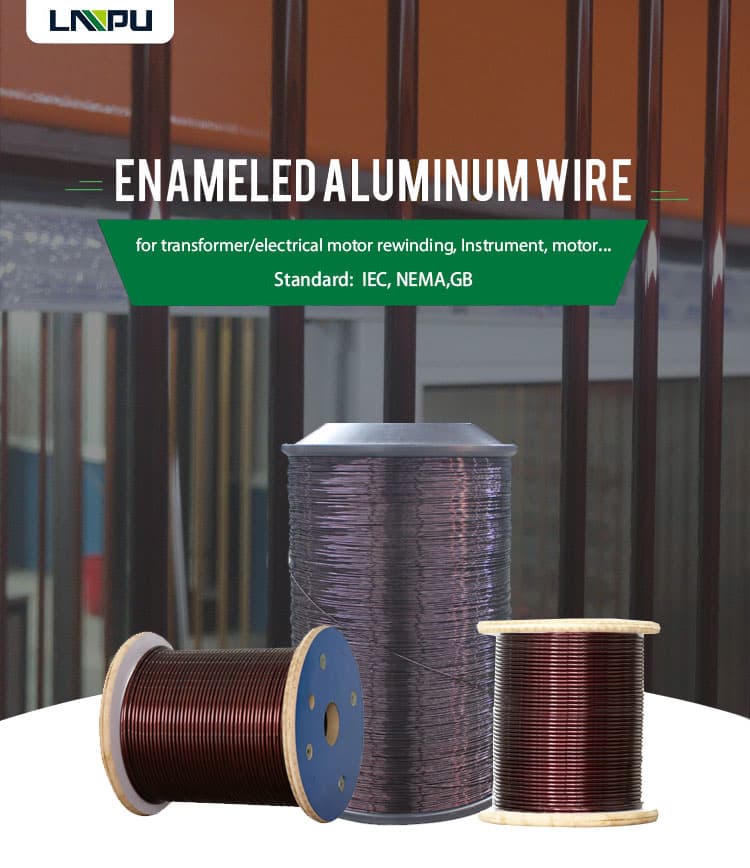

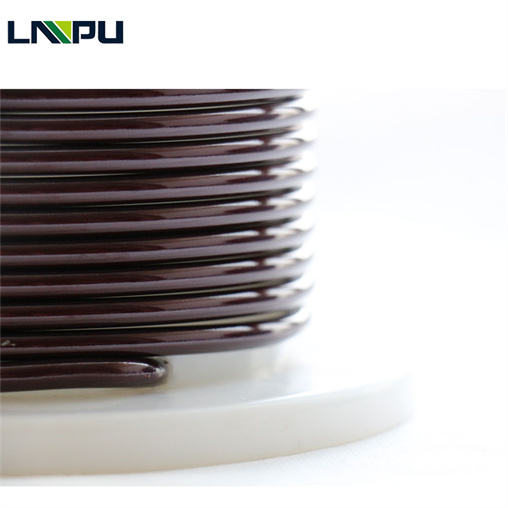

Factory Supply Insulated Aluminum Round Winding Wire Per Kilo

Factory Supply Insulated Aluminum Round Winding Wire Per Kilo normally as a sample to buyer is used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers.Thermal class 155 and 180 mostly used for low voltage transformer, the class 200 and 220 used for high voltage transformer. Insulated Aluminum Round Winding Wire is made of aluminum conductor and UEW, QZ, QZY, EIW insulation materials. LP Industry manufactures the enameled wire in accordance with the IEC, NEMA standards with UL certificate.

The characteristics of enameled wire are divided into thermal characteristics and electrical characteristics. Among them, thermal characteristics are divided into heat-resistant life, thermal shock resistance, and softening resistance; electrical characteristics are further divided into pinholes and insulation breakdown voltage. The following details are as follows:

1. Thermal characteristics

1. Heat-resistant life:

When choosing to use wires, the temperature index of the motor must be selected to determine the enameled wire, and the temperature index of the enameled wire is calculated from the heat-resistant life. The test method of heat-resistant life is ASTM D2307, and its grade is determined according to its 20,000-hour working environment temperature. Generally, the heat-resistant grade and temperature index used are distinguished by the following table quilt.

2. Thermal shock:

Thermal shock resistance is when the film is stretched and bent, heated and then immediately cooled, to see if it breaks due to thermal expansion and contraction. Generally, a wire with high heat resistance is not easy to crack even for a high heating temperature. When the wire coil diameter is small, or when the elongation rate of the coil is large, high-heat enameled wire must be selected.

3. Resistance to softening:

Softening resistance is to test the resistance of the paint film when the enameled wire is subjected to the effects of heat, force and electricity. Generally, the resistance of the enameled wire is fixed in terms of force and electricity, and the temperature is measured as an index comparison. There are heating method and constant temperature method. Two kinds.

Two: electrical characteristics

1. Pinholes Pinholes are a method of inspecting electrical defects such as fine scratches and holes in the film. Electric wires use a thin film to maintain insulation, and the thickness of the film is more than one type. Generally, pinholes are very rare, and they are almost non-existent. Another test method is high-voltage pinhole. The principle is to pass the enameled wire into high-voltage and low-current current to test whether the surface resistance is uniform. Generally, 30m is used to see the number of defects.

2. Insulation failure voltage The insulation failure voltage is to check the insulation performance of the film, and the standard is determined according to the thickness of the film of the wire. Generally speaking, two methods are used. For thin wires below 0.10mm, the metal winding method is used, and for medium and large wires, the twisting method is used. The breakdown voltage is expressed as a high value as the coating becomes thicker, and the thickness of the coating is considered based on the line-to-line voltage and the phase-to-phase voltage of the motor.