Environmental Friendly Gauge 18 Aluminum Chinese Enamel Wires

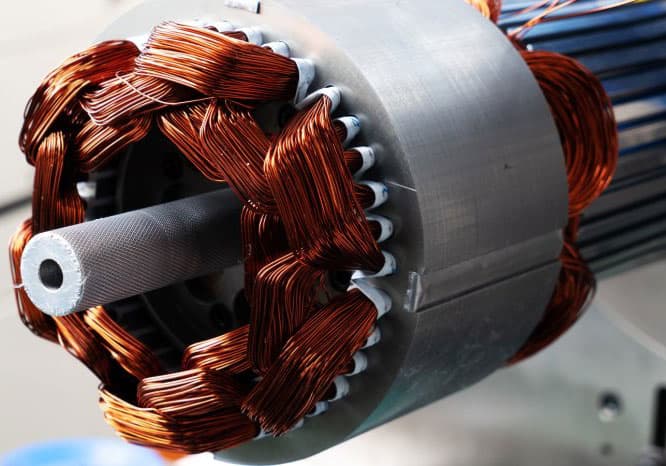

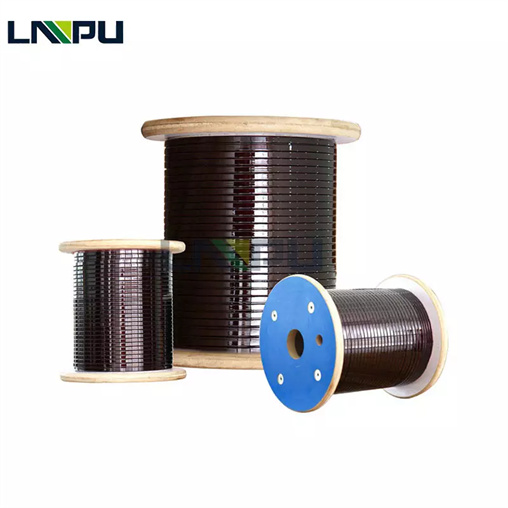

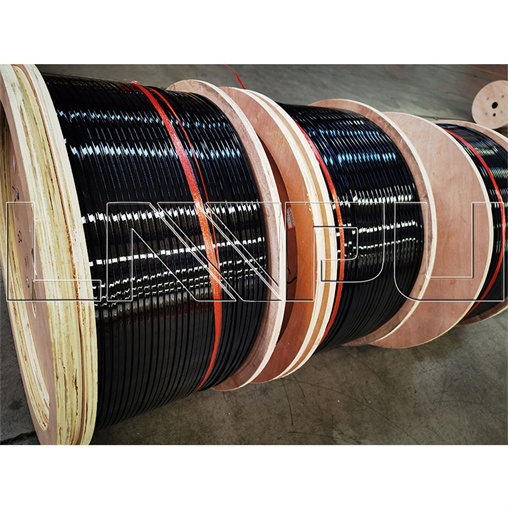

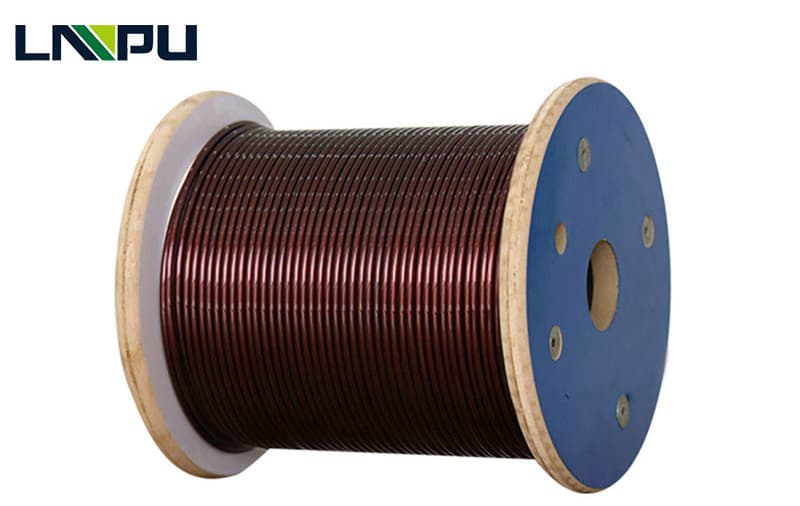

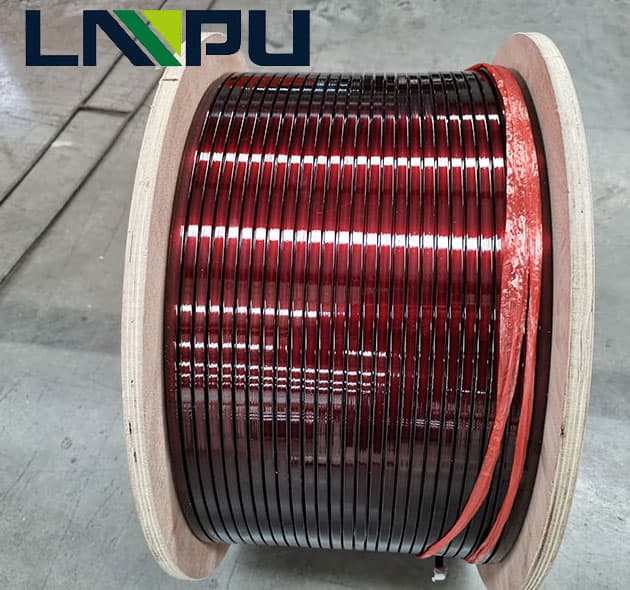

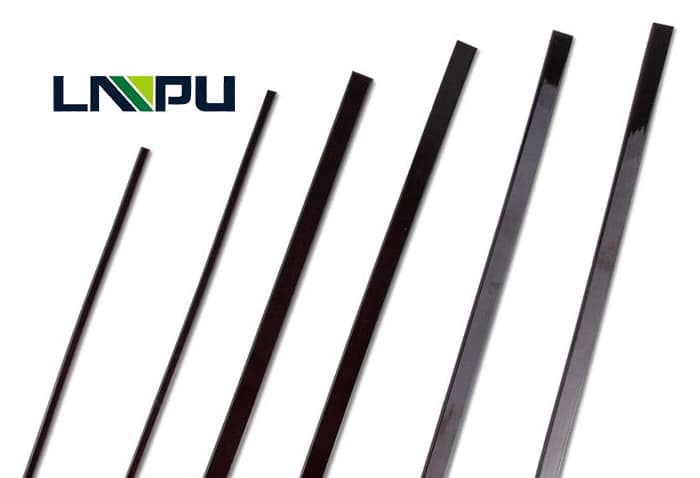

Environmental Friendly Gauge 18 Aluminum Chinese Enamel Wires are a copper or aluminium wire coated with a very thin layer of insulation. It is used in the construction of transformers, inductors, motors, speakers, hard disk head actuators, electromagnets, and other applications that require tight coils of insulated wire.The wire itself is most often fully annealed, electrolytically refined copper. Aluminium magnet wire is sometimes used for large transformers and motors. The insulation is typically made of tough polymer film materials rather than enamel, as the name might suggest.

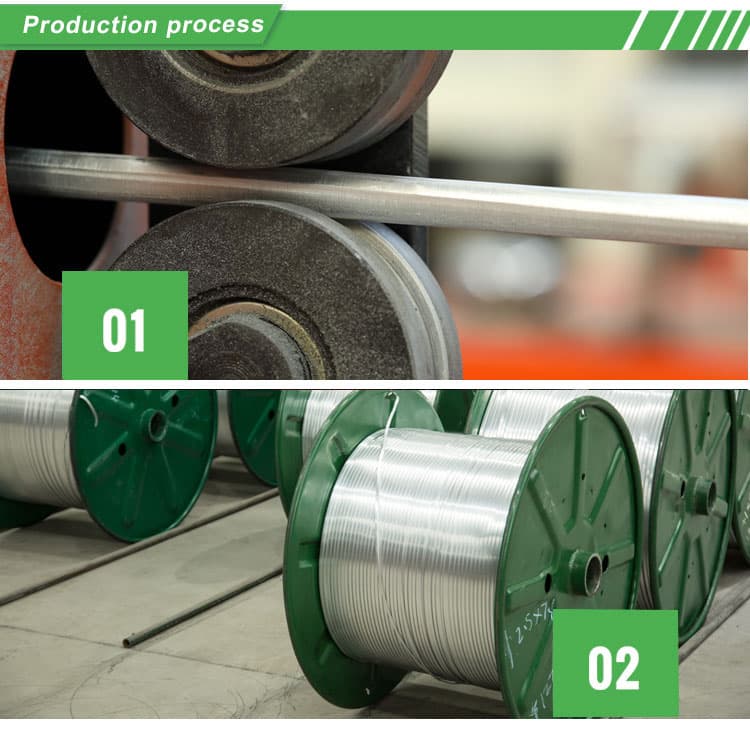

The production process of enameled wire:

Pay-off (link pull)¡úannealing¡úpainting¡úbaking¡úcooling¡úlubrication¡úcollecting money

7 steps:

1. Pay-off: release the copper material evenly from the iron shaft, provide raw materials and ensure the stability of the painting, on the high-speed machine, rely on the combined wire drawing machine to pay.

2. Annealing: Soften the bare copper wire, remove the internal stress in the stretching process, rearrange the molecular lattice, and enhance flexibility and conductivity.

3. Paint: Apply insulating paint evenly to bare copper wire, relying on mold or felt as a medium.

4. Baking: Baking is to evaporate the solvent in the paint and allow the paint base to solidify into a film to form an insulating layer. After the solvent evaporates, it is catalyzed by a catalyst and converted into Co2 and H2O, and a large amount of heat is released at the same time, thereby playing the role of environmental protection and energy saving. Catalyst composition: active components: platinum, palladium and their compounds Carrier: metal mesh, ceramics.

5. Cooling: After the wire is baked out of the furnace, its temperature is very high, and it needs to be cooled by cold air.

6. Lubrication: After cooling the enameled wire, a layer of lubricating fluid must be applied before the large coiling, which is beneficial to the customer to reduce the friction of the wire running and facilitate the wire release.

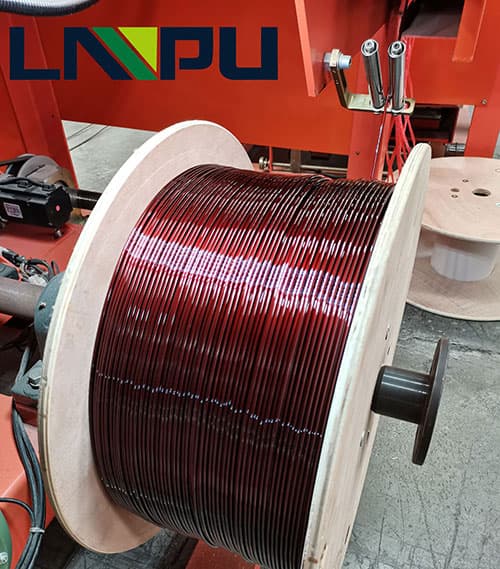

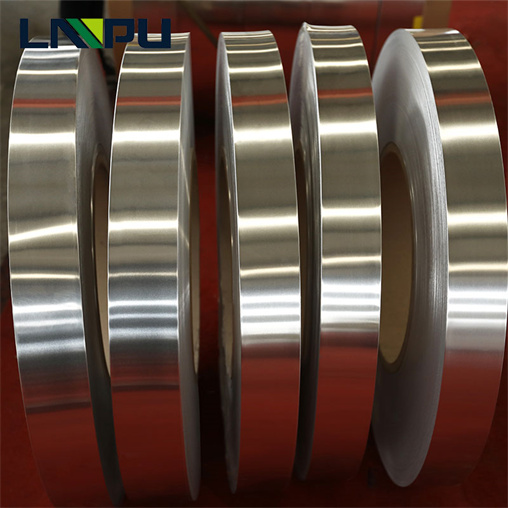

7. Take-up: After finishing the first few procedures, the enameled wire has been formed, and it is wound on a plastic shaft or a wooden shaft.