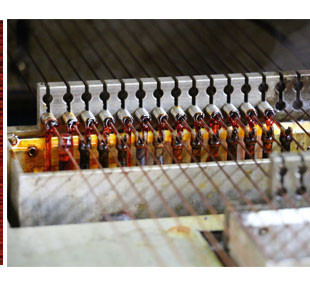

Enamelled/Fibreglass/Nomex/Paper/Mica Covered Wires

Insulation description: Enamelled / Fibreglass / Nomex / Paper / Mica

Applications: high-voltage coils, relays, transformers, hand tool motors, electronic coils, etc.

Temperature resistance grade: According to the selected bottom insulation wire, there are 130, 155, 180, 200, 220 degrees and other temperature resistance grades

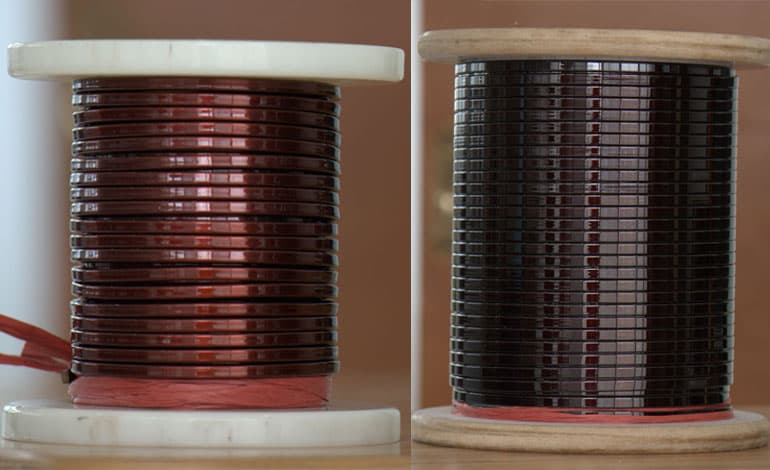

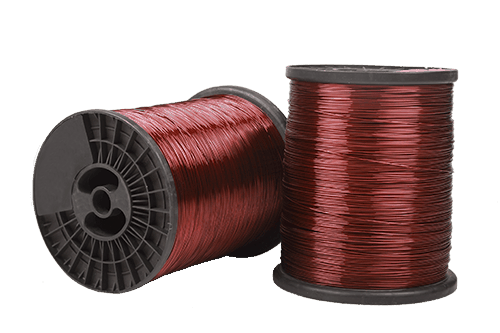

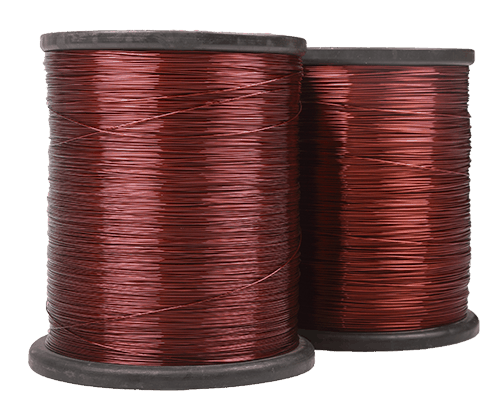

Enamelled Covered Wires: Enameled wire is a main type of winding wire. It consists of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. However, it is not easy to produce products that not only meet the requirements of the standard, but also meet the requirements of customers. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have Mechanical properties, chemical properties, electrical properties, and thermal properties are four major properties.

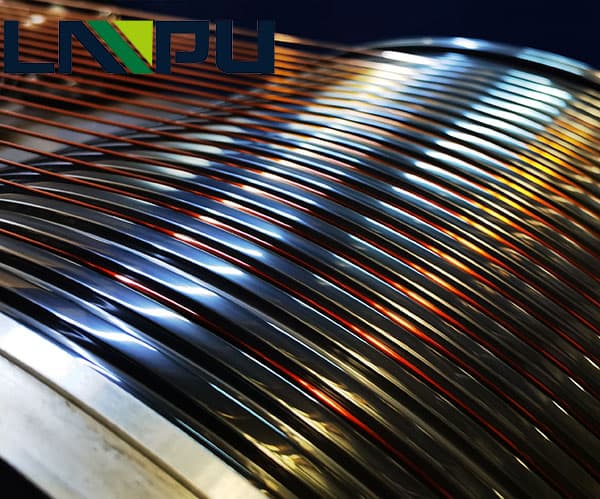

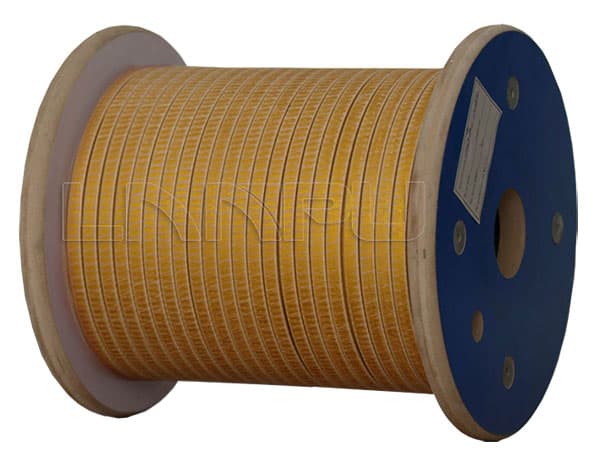

Fibreglass Covered Wires: Glass fiber high temperature resistant wire refers to a wire composed of an insulating film or a composite film and a glass fiber braid. The wire is composed of a wire, an insulating layer and a protective layer. The metal wire is wrapped with an insulating film or a composite film, plus a protective layer and a protective layer. It is made of alkali-free glass fiber woven, coated and sintered, so that the insulating layer and the protective layer are tightly combined to cover the wire. The made wire has high temperature resistance, corrosion resistance, high mechanical strength, stable insulation performance, and small outer diameter. Features, can be applied to electric heating appliances, special lamps, high temperature resistant motors and lead wires in the instrument industry and other occasions.

Nomex/Paper Covered Wires: Paper-covered wire refers to the insulation layer of the wire wrapped with cable paper. Paper covered wire insulation has at least 3 layers to wrap the paper tape. When it exceeds 3 feet, the innermost and outermost layers should be covered and wrapped, and the rest can be wrapped with a gap. The gap should not exceed 2mm. When the width of the paper tape is 9.5 When mm and above, the gap should not exceed 3mm.

Mica Covered Wires: Includes a nickel-plated or silver-plated copper conductor. The mica tape is tightly wrapped around the conductor to form an insulator. The insulator is covered with a wire sheath. The wrapping angle between the mica tape and the conductor is 35¡ãC. The wire with this structure can withstand a high temperature of 450 ¡æ, and can withstand rapid changes in temperature, and the use effect is good.