Enameling machine

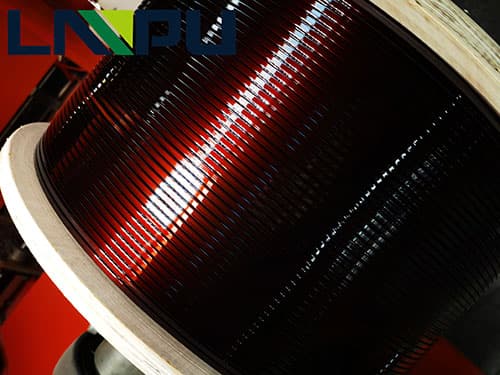

Enameling machine is an important equipment for the production of enameled wires in the magnet wire industry. Its function is to evenly wrap the processed copper wire (or aluminum wire) with a layer of insulating polyester paint. The enameled paint used in the production process of enameled wire contains a large amount of diluents and organic solvents, and the main components are benzene, xylene and cresol, which volatilize when the paint film is heated and cured, causing environmental pollution and energy waste. There are more and more manufacturers of enameled wires, and the energy saving and environmental protection of enameled machines have also become a problem that cannot be ignored.

The enameled paint used in the production process of enameled wire contains a large amount of diluents and organic solvents, the main components are benzene, xylene and cresol, which volatilize when the paint film is heated and cured, causing environmental pollution and energy waste [three organic substances have high combustion efficiency. The calorific value is generally (32406¡«43208) kJ¡¤kg-1]. During the production process, the organic matter can condense and accumulate in the pipeline, thus causing production safety problems. Most of the production plants use single-layer rapid catalytic combustion hot air circulation enameling machines for exhaust gas purification. The organic waste gas enters the catalytic combustion chamber, releases a large amount of heat energy after catalytic combustion, and then is sent to the furnace hearth of the oven through the air duct through the fan to bake the paint film coating of the enameled wire, and at the same time convert the waste gas into CO2 and water, which not only saves electricity, but also purifies surroundings. Catalysts play a decisive role in exhaust gas purification and thermal energy utilization. Such catalysts are mainly based on wire mesh or honeycomb ceramic carrier as the skeleton, coated with a certain amount of secondary coating, and then loaded with precious metals Pd and Pt as active components.

Due to the widespread use of various electrical equipment (various coils, motors, transformers, etc.), enameled wire has become an industrial product with a very broad market prospect and a very good development momentum. Therefore, there are more and more manufacturers of enameled wire. There are more than ten manufacturers of different scales and grades in Henan Province alone. The problem of energy saving and environmental protection of enameling machine has also become a problem that cannot be ignored