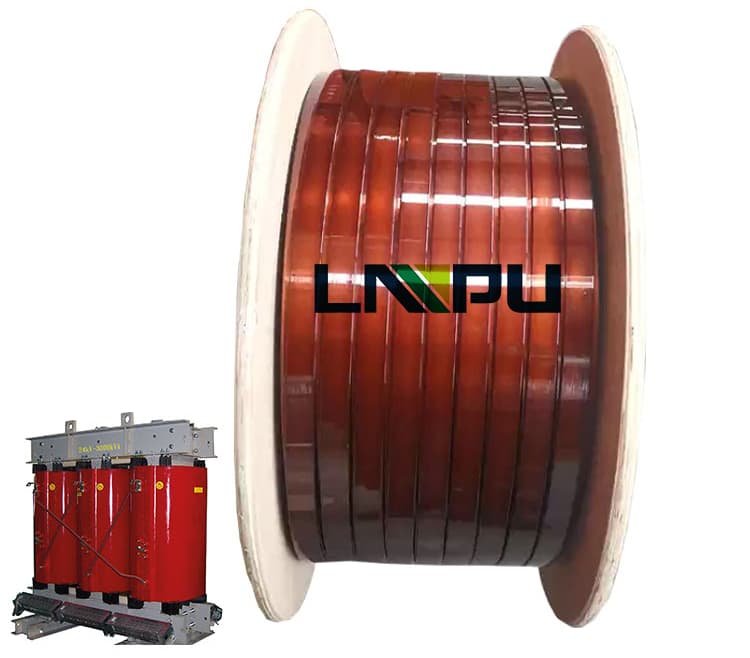

Enameled wire production process

Winding wires used in electrical equipment are usually called magnetic wires. In other words, “magnetic wires are used to exchange electrical energy and magnetic energy.” Magnetic wire is roughly divided into enameled wire (insulation coated) and coated wire (fiber/film insulation) and their combinations. The two types of magnetic wires and their performance are very different. ASTM (American Society for Testing and Materials) B193, no more than 0.017241 ohm (square millimeter/meter), the film or coating should meet the latest version of ANSI, ASTM or NEMA applicable standards, and modify the specified resin. The modified resin is Chemically changed resin, or containing one or more additives to retain the basic chemical characteristics of the original resin to enhance certain performance or application characteristics, the coated conductor needs to meet all the required test requirements of the appropriate NEMA standard (UL certification project) .

Requirements for enameled wire

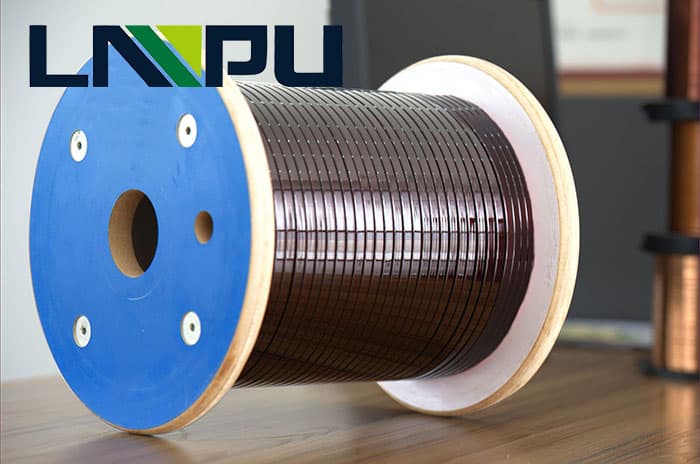

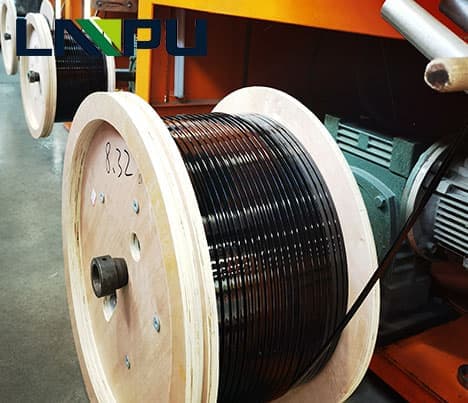

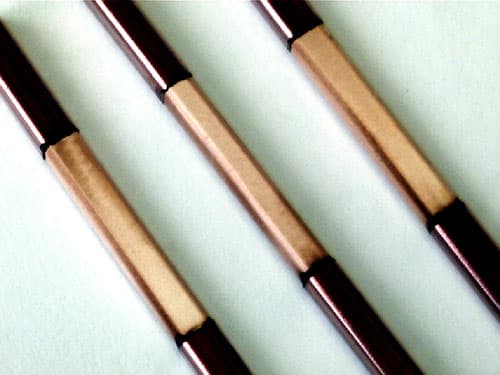

The wire should be coated or covered with a smooth continuous insulation layer, and meet the nominal diameter, the range of resistance deviation is 3.5%, the insulation layer thickness requirements are consistent, the difference does not exceed 1um, the film coating layer should be smooth and continuous, without stripes, bubbles and foreign objects .

Production process of enameled wire

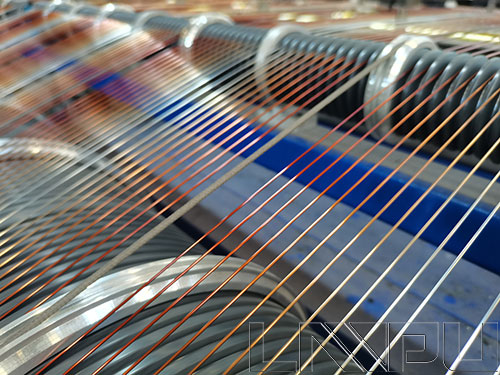

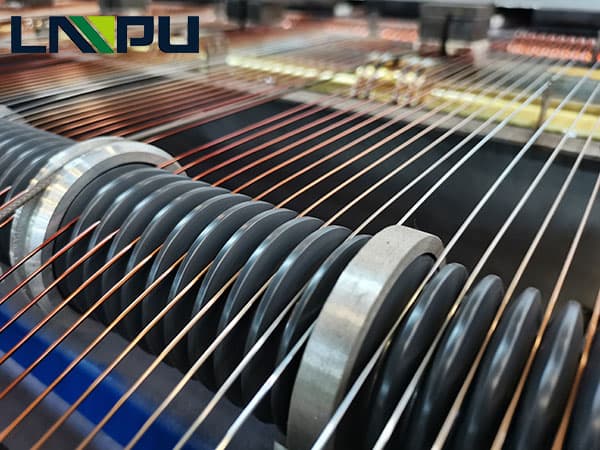

Rolling process: the pressure roller is made of tungsten steel alloy, mirror polishing processing and rolling forming technology, repeatedly make the surface of the conductor smooth and stable in size. Use the laser on-line automatic control to increase the tolerance from 0.030mm to ¡À0.005mm. The use of CNC precision cable to protect some products from mechanical damage and improve product quality.

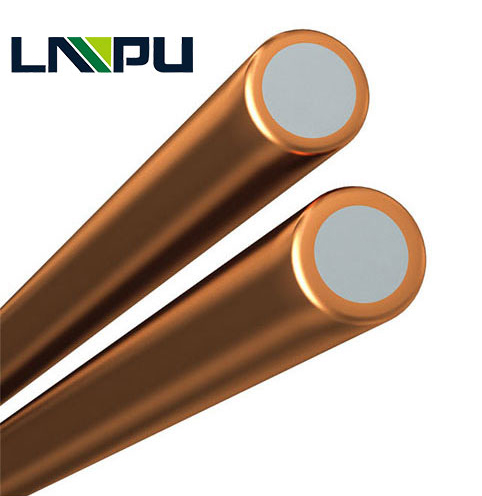

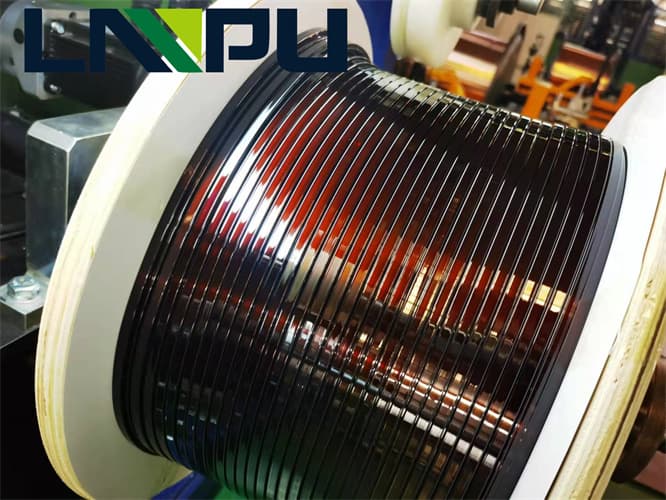

Copper wire stretching and annealing are the process of copper wire structure destruction and recovery. In the process of cold working, the diameter of the copper wire decreases and the amount of processing gradually increases. The crystal grains of the copper wire elongate and break along the tensile direction, and the density increases. The cold-worked fiber structure is gradually formed, and the mechanical performance is that the copper wire hardens, the strength increases, and the shape decreases. During the annealing process, the dislocation of the copper wire structure is reduced, the grain distribution is regenerated, the strength is reduced, and the shape and flexibility are increased.

The above indicators put forward higher requirements on the ductility and processability of copper conductors, which can be drawn with a large length and are not lined up, and the wiring is good, and meets the requirements of varnished wire pay-off. The drawing process of ultra-micro wires needs to be developed. To meet the stability and high efficiency of ultra-micro enameled wire drawing, develop a special polyurethane for ultra-micro wire.

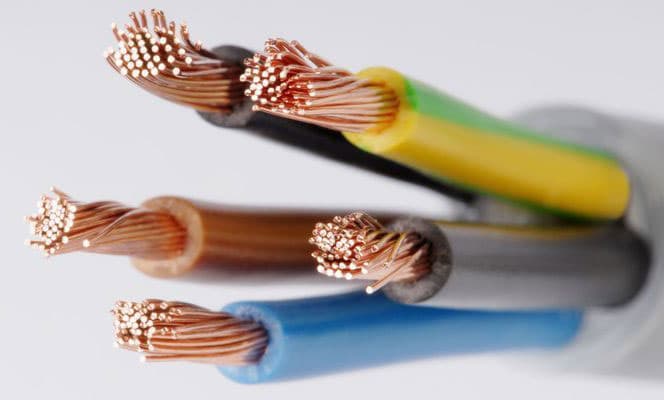

Drawing of copper wire

Copper wire generally uses oxygen-free copper without hydrogen embrittlement. Oxygen-free copper has electrical conductivity and processing properties. The deformation methods of copper wire at room temperature are slip and twinning. The finer the grain, the more the grain boundary, the more difficult it is to shape and deform. The higher the strength and plastic toughness, the structure and grain of the copper wire must have a good distribution and sufficient size to obtain better elastic performance.

The drawing die of copper wire is divided into four parts in the entrance zone, compression zone, sizing zone and exit zone. The internal contour of the drawing die is very important to the process of copper wire, which determines the required tensile force of the copper wire and the residual copper wire after drawing. stress. The entrance area is convenient for the copper wire to pass through the mold smoothly to avoid damage to the copper wire and the mold contour. The compression zone, the forming area of ??the drawn copper wire, the copper wire reduces the original cross-sectional area to the nominal cross-sectional size. If the copper wire is tapered, the compression zone is located in a cylinder, and the cone half angle of the compression zone Used to determine the size of the pulling force. The sizing area is used to obtain the exact size of the copper wire. The length of the sizing area depends on the material itself and the diameter. The exit area prevents the copper wire from flowing out of the drawing die smoothly without damage to complete the drawing process. The unreasonable design of drawing die and drawing process will increase residual stress and lead to unqualified wire diameter, increase machine energy consumption, and increase manufacturing cost.

The industry uses Wistreich simulation and experience to obtain parameters related to compressibility and taper angle to guide process design, eliminate and avoid residual stress in the manufacturing process. The diameter of the copper wire is stretched from large to small, for example: 8.00mm->2.60mm (no annealing)->1.24mm (annealing)->0.08mm->0.022mm.

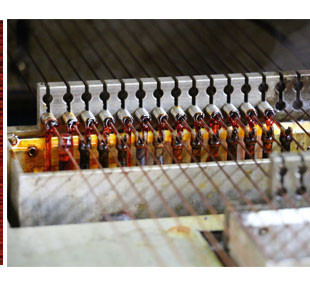

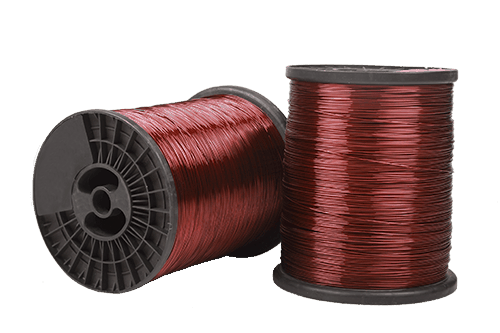

The choice of paint film material is generally determined by the type of resin used for the primer and outer coating, the name of the insulation thickness, the application of the magnetic wire, and the packaging size of the spool (spool), reel or container. Polyurethane coatings are generally polymerized by polyisocyanates and polyols. Thinners are added to adjust the viscosity. Insulating materials generally include polyurethane toluol leveling agents. Different contents will affect the performance of the paint film, including breakdown voltage, softening breakdown voltage . Painting methods are generally divided into two methods: mold and felt. For larger diameters, select molds for painting, and for thinner diameters, select felt for painting. Lubricants generally use 200# solvent oil 70-80%, n-hexane 15-20%, 7# white mineral oil 3-5%, 46# refrigerating oil 1-2%.

Conclusion:

The polyurethane insulation formula of the copper wire paint film not only meets the consistency of the insulation thickness, but also provides better mechanical, electrical, chemical and thermal properties, increases the leveling during the copper wire drawing process, and achieves excellent surface lubricity of the enameled wire. Apply an even target. If the insulating film is decomposed, the decomposed components will cause damage to inhalation and skin contact. Avoid being ignited by fire, static electricity, sparks, etc., and do not mix peroxides, strong acids, strong alkalis, strong alkalis and other oxidants. Use a ventilation system or use chemicals, solder, etc. to remove the insulation film of the wires, and do not inhale harmful decomposition gases. Do not touch chemicals, solder, etc., with gloves, and waste materials generated by proper burning or burying.