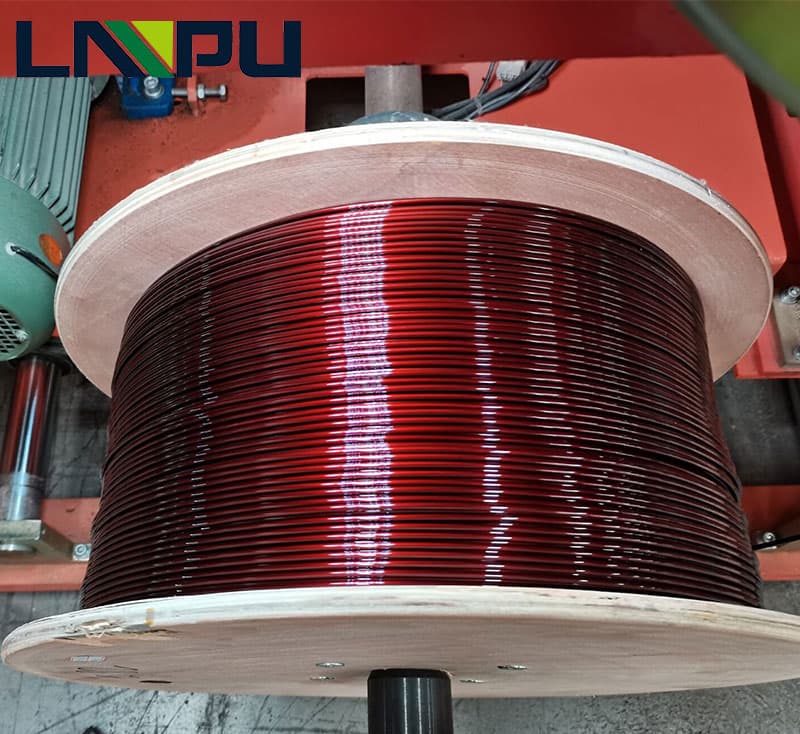

Enameled Wire performance introduction

Anti-electricity-firecable wire

2. Aluminum winding wire

3. Three-layer extruded insulation wire

1. Anti-electricity-firecable wire

With the development of electric electronics technology, the frequency conversion speed has been developed rapidly, and the most attractive inverter motor is saving energy. my country’s total capacity is about 60% is on the motor, while the frequency converter can make the motor to save 20% energy. Infrequency, in addition to energy saving, in addition to energy saving, in addition to energy saving, in addition to energy saving, in addition to energy saving, and improves the process level, product quality, production production and efficiency of the product. Wait. These are very difficult to use% to measure. Therefore, the variable frequency adjustment has a broad application prospect. And will gradually replace DC speed speed. With the rapid expansion of frequency conversion product applications, its service life is increasingly prominent. After use IGBT (Insulated Gate Bipolar Thyristor) Technology PWM (Pulse Width Modulation) Switch After use, the variable high frequency and a large number of instantaneous pulse spikes can cause corona discharge phenomena to make the motor inside. Sometimes, the insulating life is only 1-2 years, sometimes it is only a few months to insulate it. The most common insulation damage is from the turns, which is caused by a variety of factors such as local discharge (generating corona), local media heat and space charge accumulation. Therefore, a number of measures to improve the life of insulation systems are put forward for possible reasons. The electromagnetic wire in the insulation system is an important part. In recent years, advanced industrial countries have carried out research work of new electromagnetic wires.

In recent years, the development of nanotechnology has improved the improvement and improvement of the inverter motor, has created conditions, developing average phase, transparent and coating better paint not only beneficial to the production of wires, but also enables the enamel wire. The performance is better and may result in new features to expand the application surface of the paint package.

In the face of advanced technology, many companies in China have also started, with foreign experience, imported paint, developed high-frequency motor enameled wire. Domestic research institutions, Shanghai Electrical Appliances, Shanghai Cable Research Institutes also conducted research work varying degrees, from the study of insulation paints, preparatory test bases, custom wires and motors. Work is in succession and has achieved certain results.

The inverter motor has made a long progress in the past few years in the enameled wire. However, due to factors such as price and application, it is currently in the stage of research and development. The development of the enameled wire is still in the expansion of the application. For example, the inverter air conditioner in the household appliance market is very popular, the frequency conversion refrigerator, is very fast, but it is not known to use the upconcibble wire. However, it is certain that metallurgical, rolled steel, mine, railway, transportation and other industries have been used or prepared to adopt a variable frequency motor enameled wire, and most of them are imported from abroad.

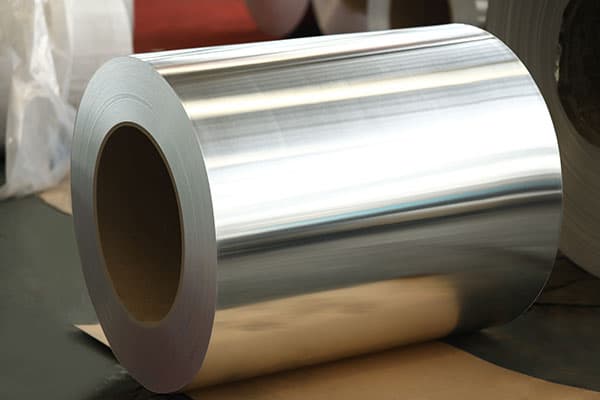

2. Aluminum winding wire

Aluminum as a winding wire core in the 1960s in China, in China, all paint wires produced painted aluminum wires, but due to aluminum conductor liveIn its own resistivity, low tensile strength, low tensile strength, large processing difficulty, welding difficulty, etc. At that time, the price of copper prices and aluminum prices were very small, and therefore, aluminum as a lacquered wire conductor gradually withdrawed from the historical stage, in China Almost no manufacturer is produced.

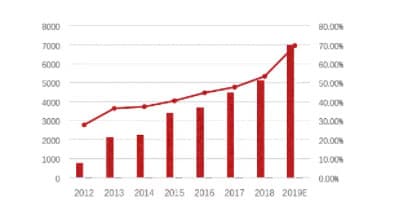

In recent years, due to the large increase in copper prices, aluminum wire has a small proportion, low price, rich resources, and special occasion, aluminum as a wall of the wall, has been headed, and China has There are electric machines in Yantai Dongshan, Tongling Jing, Wuxi Jufeng, etc. Production of full-painted aluminum wire, Tianjin Jingwei Electromagnetic wire produces winding aluminum wire, optimistic, mainly for microwave transformers, reactors, degaussing coils, electroacoustic Devices, lighting rectifiers, etc.

Aluminum is used as a winding wire conductor and a copper ratio, and the characteristic parameters are listed in Table 23, and the tensile strength of the copper wire is twice the aluminum wire.

Aluminum wire is different from copper wires as a lacquered wire, and there is a special difficulty. During the wire drawing process, it is extremely easy to disconnect during the drawing process. The hardness and wear resistance are not as good as copper, so the surface is easily wounded, and the surface of the painted lacquer wire often has a lot of bright spots, beads, and aluminum points. At present, the aluminum wire wire drawing wire is minimum is ¦Õ0.15 mm. In addition to surface finish differences in the draw, the surface of oil and aluminum powder are still another problem. Comprehensive analysis must be modified, analyzed, trial, and research on equipment tool tools, mold ratios, lubricating liquid formulations. Effectively overcomes the disadvantages of frequent disconnection, surface oil and lightness of the surface during the use of other brushed lubricants at home and abroad. Lubrication is to reduce the friction coefficient between steel and aluminum and aluminum and aluminum, and it has a powerful cleaning function on aluminum powder and oil.

Although the corresponding above measures were taken during the drawing process, the surface of the relatively cleaner aluminum wire was drawn, but the surface had oil, aluminum powder, without meeting the requirements of the coated paint. During the coating process, there is a conventional felt scrub, paper scrub, and water cleaning cannot achieve the ideal cleaning effect. Therefore, it must be a highly efficient cleaning device and a special cleaning solution before the coating wire to meet the cleaning requirements of the aluminum conductor paint. In order to solve long-term troubles of aluminum painting wire due to the surface of the enameled wire, the surface of the lacquer wire, the gum, highlights such as the surface of the aluminum powder, and the quality problems such as the surface of the lacquered wire.

In order to improve the high full discretion rate of the paint package process, overcome the characteristics of the aluminum, high-wire expansion coefficient, low tensile strength, using traditional paint machine production of painted aluminum wire, lead tension is extremely difficult Control, resulting in an easy to stick, disconnection, full discretion, and extremely low overall rate (especially for fine painting binated aluminum wire). To this end, it is necessary to transform the key parts of the traditional enameled equipment, which greatly reduces the probability of the sticky wire and the disconnection.

Because aluminum resources are much rich than copper resources, the price is low, the application of the enameled aluminum wire can greatly reduce the cost of electrical products, and the specific gravity of aluminum is about 1/3 of the proportion of the copper, and the aluminum paint brown wire can make the electrical appliance The product is lightweight, and the damage during freight and transportation is reduced.. For the enamel wire manufacturer, the enameled aluminum wire can greatly reduce the amount of flow funds and reduce financial expenditures. The production of aluminum wire production is high, and the added value of production is also high, and better economic benefits can be created.

From the scope of the application of the lacquered wire, it is limited to a short-term use of microwave, reactor, and less considerations for energy consumption. However, since the resistivity of aluminum is higher than copper, it is necessary to achieve the same outstanding rate and efficiency of the copper wire in the design of the electric machine, and the cross section and length of the aluminum wire must be increased, resulting in an increase in the volume of subsequent products, other supporting The material also increases, and it is more important that the resistivity increases, and the energy consumption has also increased, so the electric machine operated for a long time is limited by the enamel aluminum wire.

In addition, the rise of aluminum wires, a big factor is the rise in copper, but once the copper price falls, the price of aluminum is rising, and the production of aluminum paint brings will bring risks. Therefore, entrepreneurs should consider their adverse and disadvantages when investing in the enameled aluminum wire.

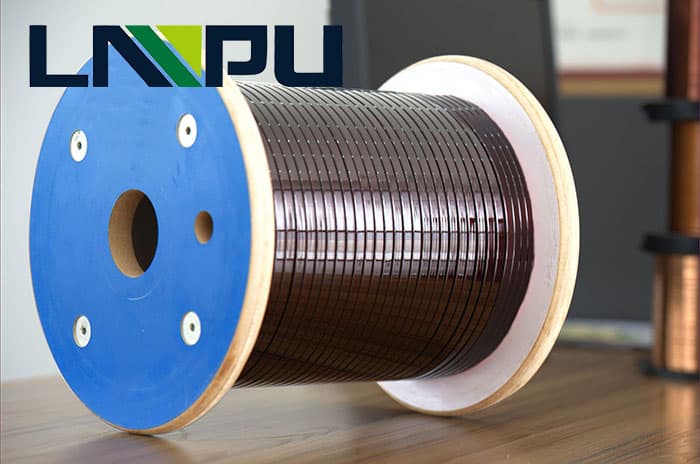

3. Three-layer extruded insulation wire

The extruded insulation wire is a new variety proposed in recent years. It is mainly used for the maximum characteristics of high-frequency electron transformers and high frequency electron transformers. It is high-frequency, from the principle of working principle of the transformer, improve the working frequency can reduce the volume and weight of the transformer, that is, minimize, thus increasing the unit volume (or weight) transmission power, which is high power density. With the development of the overall structure of the high-frequency electron transformer, the main development direction of the coil structure is the planar coil, the chip coil, and the film coil, including the multilayer structure, the high-frequency transformer coil of the stereo structure is used with three-layer extruded insulating coil. . Increased allowing temperature rise and shrinks the volume of the coil. The most typical example is the charger of the phone.

The insulating layer of the extruded insulation wire is different, and the insulating layer of the extruded coating is generally thicker, so the insulation wire has its own unique performance.

The three-layer insulation wire of China has also developed research, and Taiwan has a large number of companies. At present, there is still a large part of imports in China.

At present, the key to the development of three-layer extruded insulation wire in China is in precision extrusion technology and equipment, the material is mainly relying on imported, three-layer co-extrusion equipment, especially thin layer extrusion equipment is still in research. Process research is a starting stage. Therefore, the research pace of material technology and equipment should be accelerated to meet the needs of extrusion insulation wires.