Enameled Wire Infrared Spectrum Analysis and Test

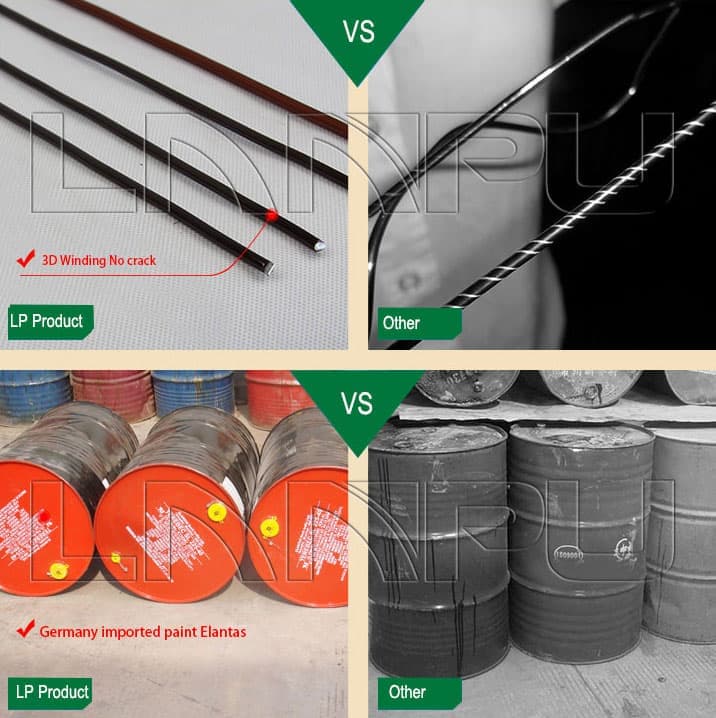

The infrared spectrum analysis test is based on the standard UL746A, which only confirms the chemical composition of the paint film, establishes the infrared spectrum and retains it. After the enameled wire is certified, samples will be sampled for testing every year during the follow-up inspection service. The infrared spectrum made by the paint film on the sampled sample needs to be compared with the infrared spectrum established on the sample at the time of certification. The two infrared spectrums must be comparable. superior.

In addition to infrared spectrum analysis, in the annual follow-up inspection service, two tests are required for the enameled wires extracted on site: dielectric strength test and tensile and thermal shock test, but thermal aging test is not required. In theory, the sample required for certification is the fully cured enameled wire. If it is an incompletely cured enameled wire, there will be two risks. One is that the performance of the aging test may be affected during certification, and the other is the follow-up follow-up inspection sampling. There may be spectral differences.