Enameled wire heat aging test

In the long-term thermal aging test, three or more temperature points are usually selected for accelerated aging, commonly known as “three-point aging”.

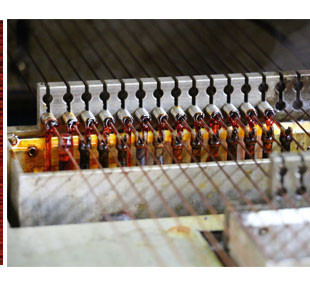

The samples for the aging test are stranded enameled wire pairs. The production of the stranded pairs should meet the requirements of ASTM D2307 or NEMA 1000 standards, including the weight to be applied when making the stranded pairs, the number of twisted turns, the effective length of the stranded area, and The length of the two ends of the twisted pair, etc. When making a twisted pair, the required force and the number of twist turns will vary depending on the diameter of the wire. The effective length of the stranded area has nothing to do with the wire diameter, the effective length is 121¡À6 mm, and the two ends are at least 50 mm long. At least 10 twisted pairs per temperature point and mounted on twisted pair racks for high temperature aging test.

High temperature aging test process:

Screen the samples first by placing them in the oven to ensure that all test samples are compliant. After the completion of aging, the samples are aged. After each aging cycle, a withstand voltage test is performed. After the test, the next cycle of aging is continued until the 10 twisted pairs at each temperature point are withstand voltage breakdown, and the aging test is over. , for data analysis.

How to select three test temperature points for three-point aging?

The selection of the test temperature point is based on the temperature grade applied by the customer. Usually, the low temperature point will be tested at the application temperature grade +20¡ãC, the medium temperature point is the low temperature point +20¡ãC, and the high temperature point is the medium temperature point +20¡ãC. For example, if the temperature class applied by the customer is 180¡ãC, then the three aging test temperature points are usually set at 200¡ãC, 220¡ãC and 240¡ãC.

The initial aging cycle for each temperature point is set according to the standard ASTM D2307 Table 3. In fact, during the aging test, it may be necessary to increase the temperature point according to the actual test situation, and it may also be necessary to adjust the aging cycle.

Data requirements for three-point aging test of enameled wire:

The theoretical basis of the data analysis of enameled wire aging test is “Arrhenius equation”.

After the test, the log average hour of aging at the low temperature point shall not be less than 5000 hours, and the log average hour of aging at the high temperature point shall not be less than 100 hours. In addition, the correlation coefficient of the slopes fitted by the three temperature points shall not be less than 0.95. Otherwise, all will be considered test non-conformance. In the case of meeting the above requirements, we will analyze the aging test data to calculate the temperature level that the enameled wire can achieve.

How to choose a temperature point for aging?

According to the standard UL 1446 SB4.4, the temperature point where the aging time is close to 1000 hours in the test data of the enameled wire paint that has obtained UL certification is usually selected for testing. If there is no temperature point with an aging time close to 1000 hours, the temperature point with an aging time close to 1000 hours will be selected according to the linear relationship of the original test data of the enameled wire paint. At this time, this temperature point is different from the original test temperature point of the enameled wire paint. After the aging temperature point is over, bring it into the slanted line of the original evaluation of the enameled wire paint to fit, and the correlation coefficient shall not be less than 0.95, otherwise, it will be regarded as not conforming to the test.