Enameled wire characteristic test

¡ñ Conductor resistance. Measure with a conductor resistance tester, and then change to the value at 20¡ãC for comparison.

¡ñInsulation destruction voltage. Twist two enameled wires, apply voltage between the conductors, and judge by the damage voltage of the paint film. This performance is analyzed and judged through two tests of normal state and cold state breakdown voltage.

¡ñPaint film continuity (pinhole). Check the small holes of the paint film with a certain length of the test material. The project is tested by a high-pressure paint film continuity tester.

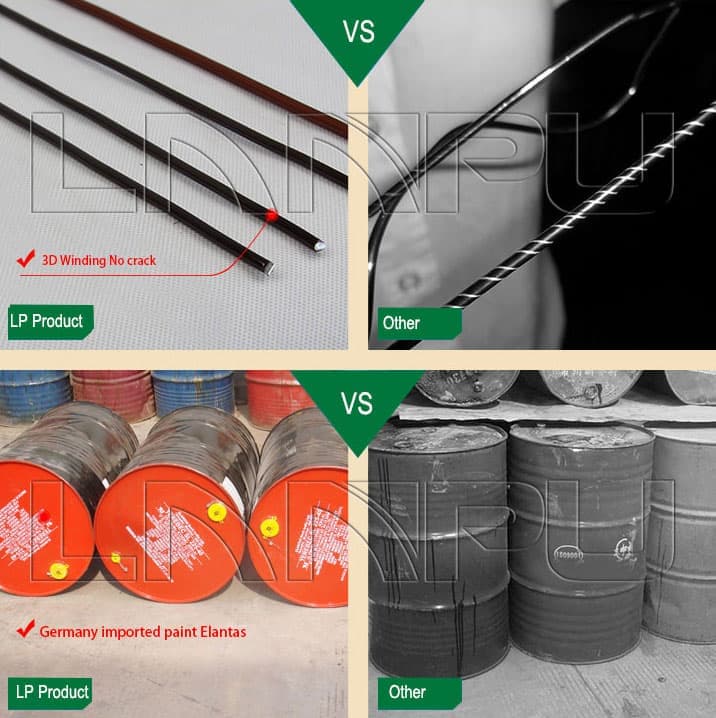

¡ñFlexibility (flexibility). When winding or stretching, judge whether the paint film is cracked or pinholes are generated.

¡ñAdhesion. The paint film should be cracked when it is stretched rapidly.

¡ñAbrasion resistance. When the paint film is abraded by the abrasion tester, the number of times of abrasion until the conductor is seen or the abrasion damage value is measured by the scratch-resistant paint tester.

¡ñAging resistance. When heating under specified conditions, analyze whether the paint film has pinholes or insulation breakdown voltage value.

¡ñSoftening resistance. Heat the crossed enameled wire under the specified conditions, and after energizing, use the temperature value for whether there is a short circuit or a short circuit occurs. Or twist two enameled wires and heat them under specified conditions, depending on whether the paint film is abnormal.

¡ñHeat shock resistance. When stretching or winding, heat under specified conditions, depending on whether the paint film is cracked.

¡ñSolvent resistance, chemical resistance and oil resistance. When immersed in solvents, chemicals or insulating oil, the state of the paint film is indicated by the nail method or the pencil method.

¡ñStraight solderability. According to the specified conditions, temperature and solder, depending on whether the solder is evenly attached.