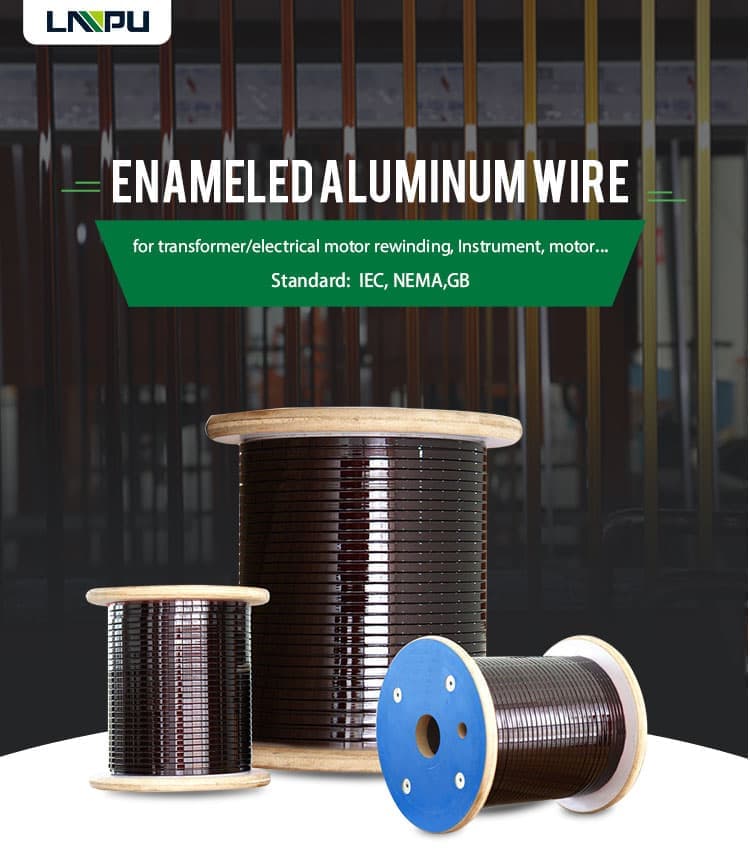

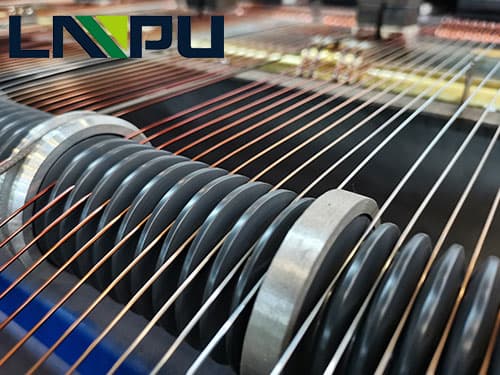

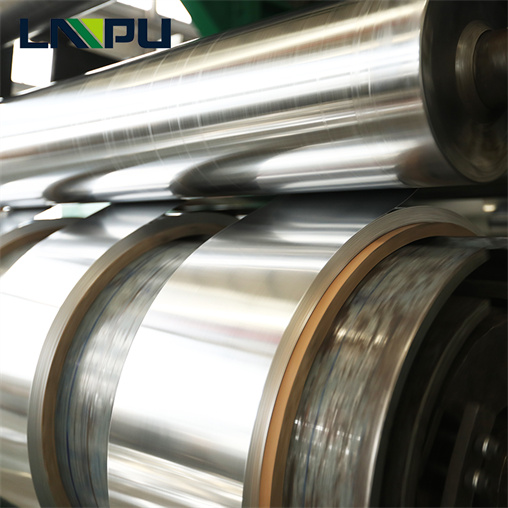

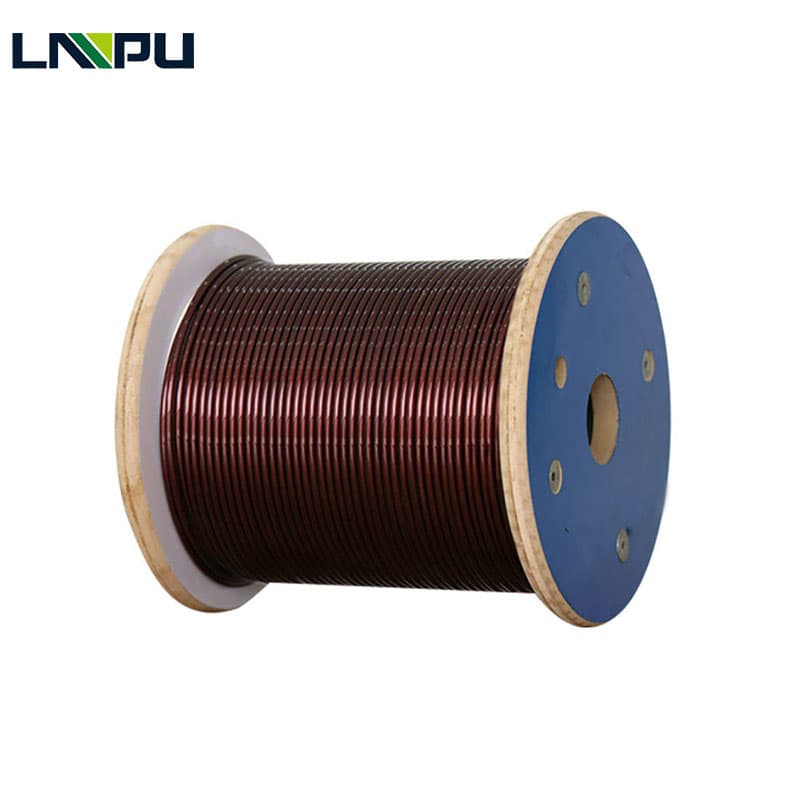

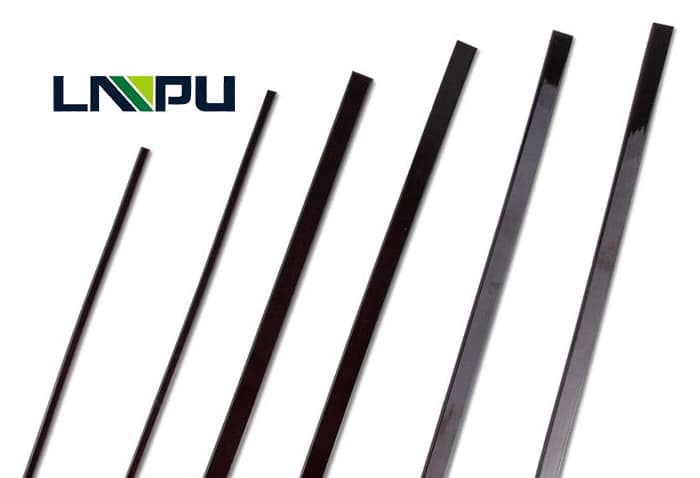

Enameled Magnet Aluminum Wire Strip

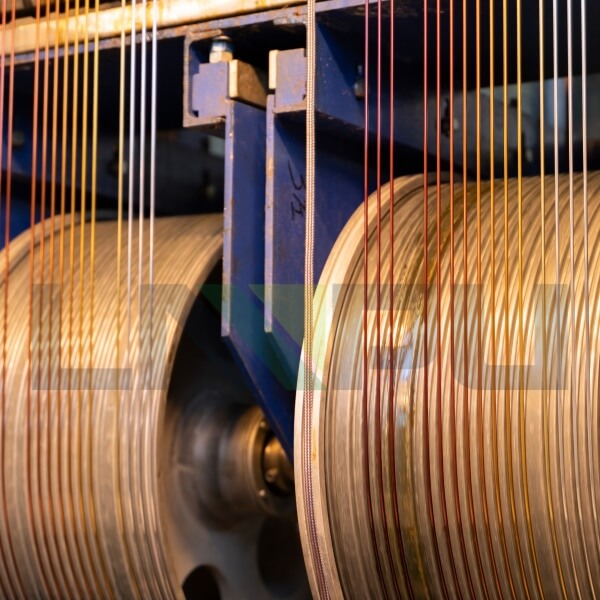

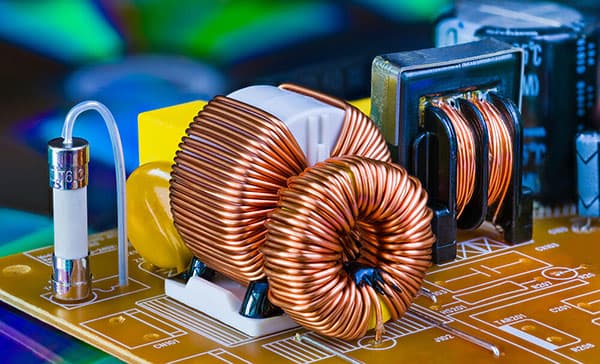

Enameled Magnet Aluminum Wire Strip for winding used in electrical equipment is generally called magnet wire. Simply put, ¡°Magnet wire is used for interchanging electrical energy with magnetic energy¡±.

Magnet wires are broadly divided into enamelled wire (coating insulation), covered conductor wire (fiber/film insulation), other specially formulated wire, and combinations thereof.

Both type and performance of magnet wire are quite varied. The following are the most important features of magnet wire:

(a) Small and uniform insulation thickness;

(b) Good electrical characteristics such as dielectric strength and insulation resistance;

(c) Tough coating, resistant to external forces such as bending, stretching and friction;

(d) Heat-resistance;

(e) Resistant to solvents, chemicals and varnishes;

(f) Resistant to hydrolytic degradation;

(g) Stable when combined with insulating material;

(h) Resistant to water and moisture;

(i) Easy to use;

It is difficult to provide all of these characteristics in one product. Each type of wire has its own advantages and disadvantages. Therefore, it is important to consider operating conditions in order to select the correct product.