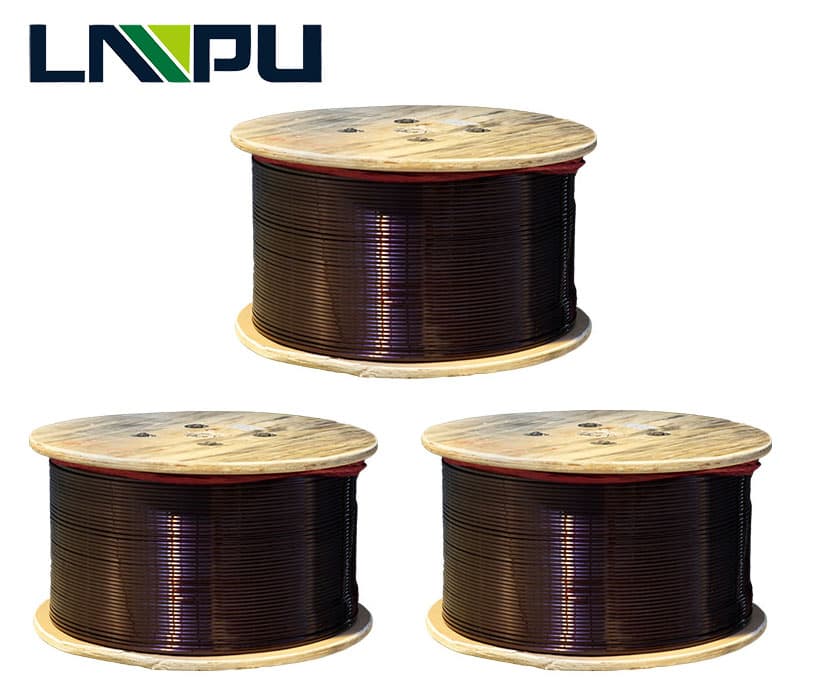

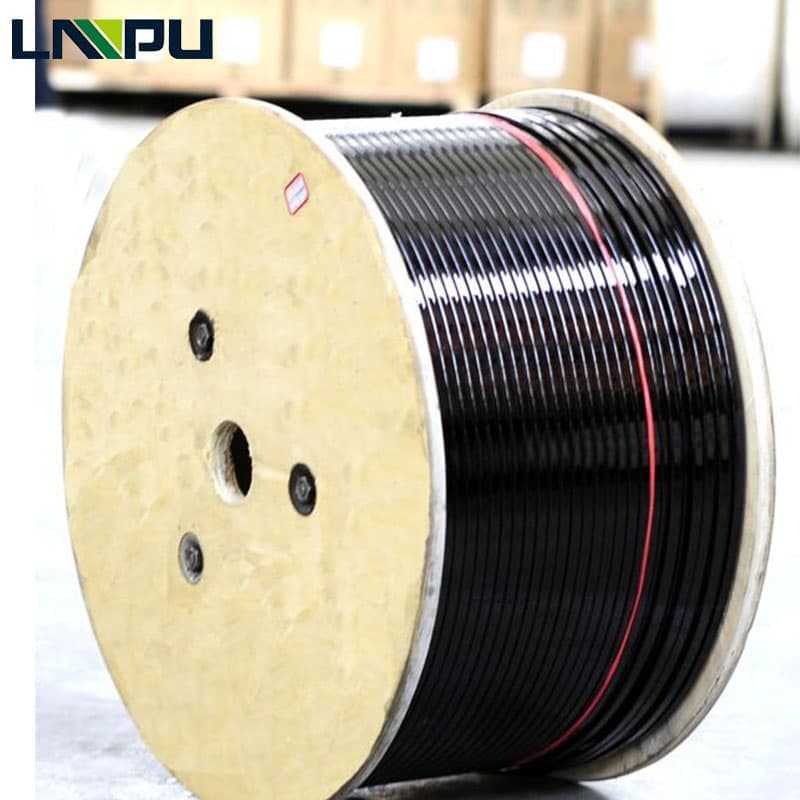

Enameled Copper Coating Aluminum Wire

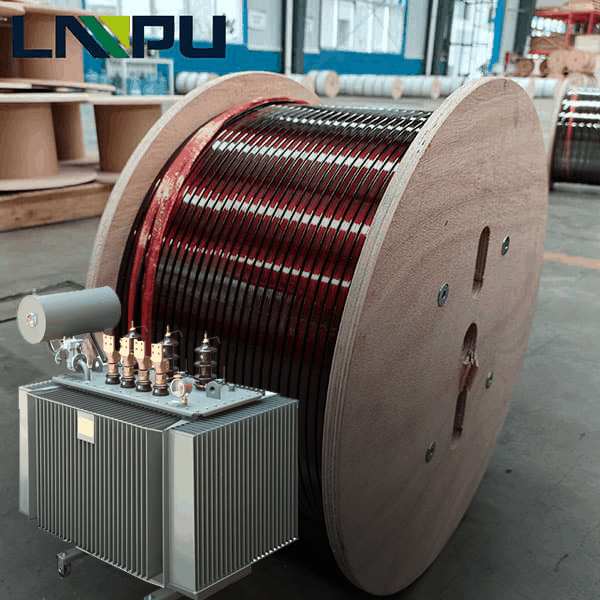

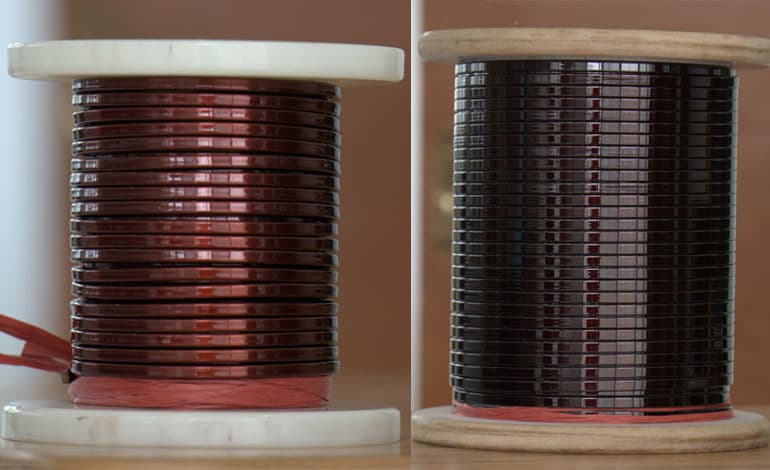

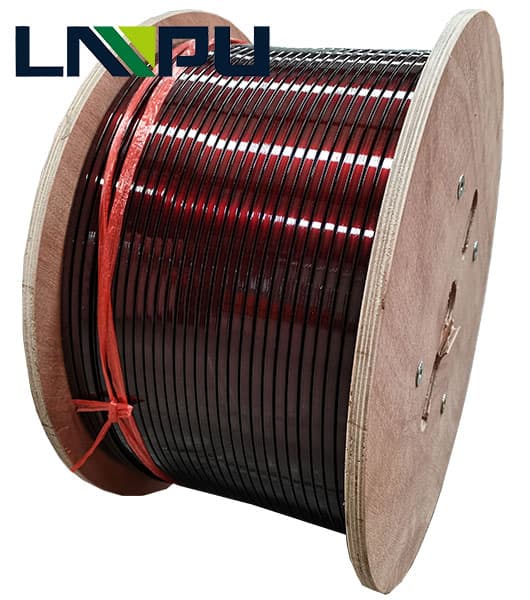

Enameled Copper Coating Aluminum Wire refers to the wire with aluminium core as the main body and a certain proportion of copper coating on it. It can be used as conductor of coaxial cable and conductor of wire and cable in electrical equipment.Polyurethane enameled wire; thermal grade 130, 155, 180, 200. It is characterized by direct welding, good high frequency resistance, easy coloring and good moisture resistance.

Compared with pure copper enameled wire, copper clad aluminum enameled wire has obvious advantages:

1. Light weight

The density of copper clad aluminum wire is 1/3 of that of pure copper wire of the same wire diameter, which is very effective in reducing the weight of cables and coils. In the field of audio coils, it significantly improves product performance.

2. Good DC resistivity

The DC resistivity of copper clad aluminum wire is about 1.5 times that of pure copper wire; when the resistance value is the same, its wire diameter is about 1.2 times that of pure copper, while the weight of copper clad aluminum wire is only 1/2 of that of pure copper wire.

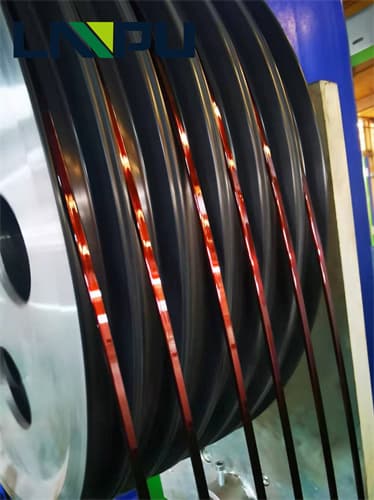

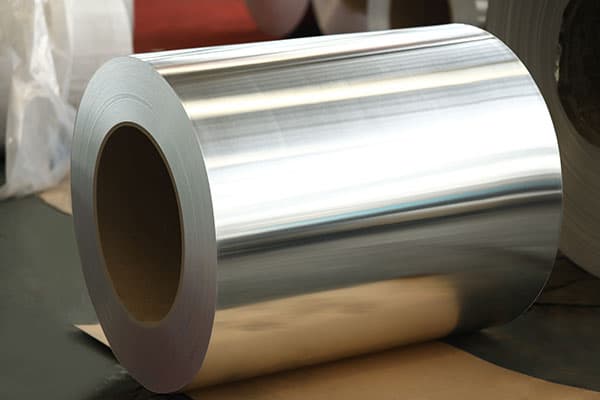

3. Good brazing properties

Copper-clad aluminum wire is concentrically coated with a layer of pure copper, so it has the same solderability as pure copper wire, without special treatment like aluminum wire.

4. Low cost

Compared with pure copper enameled wire, copper clad aluminum wire can reduce the production cost by 30%-50% in some application fields.