Enameled Copper/Aluminum Wire For Motor

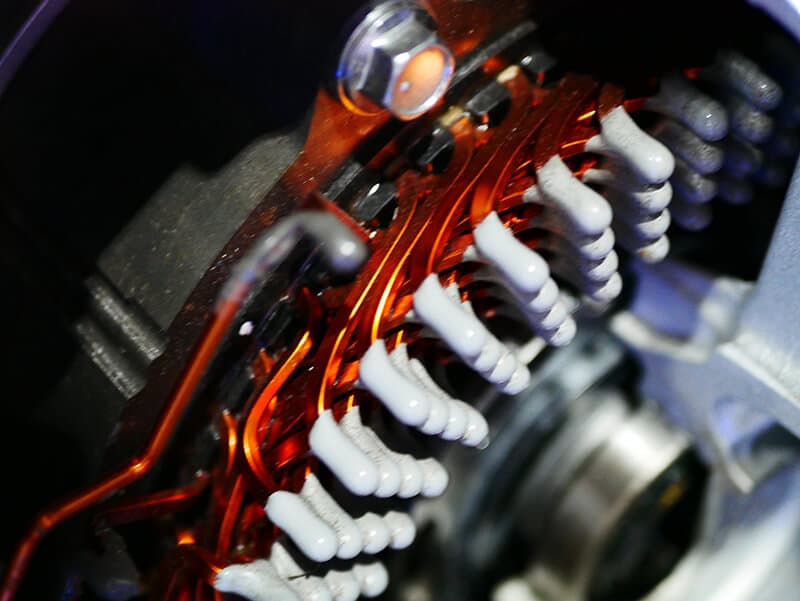

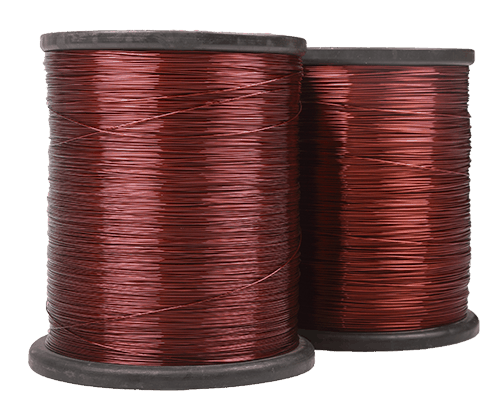

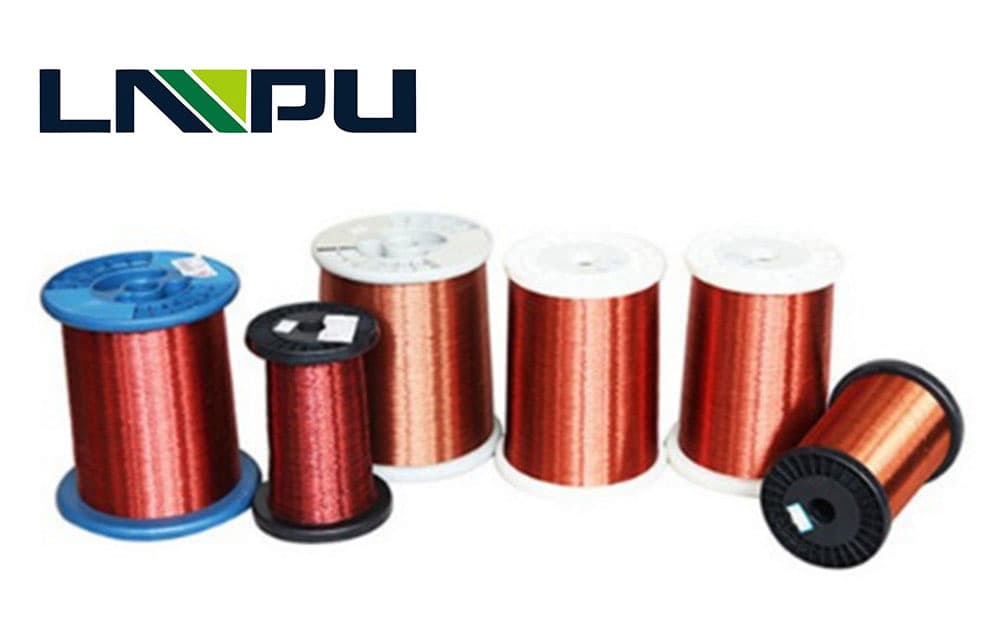

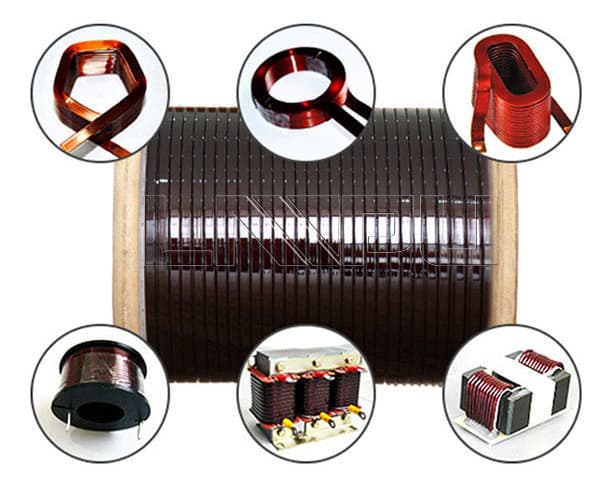

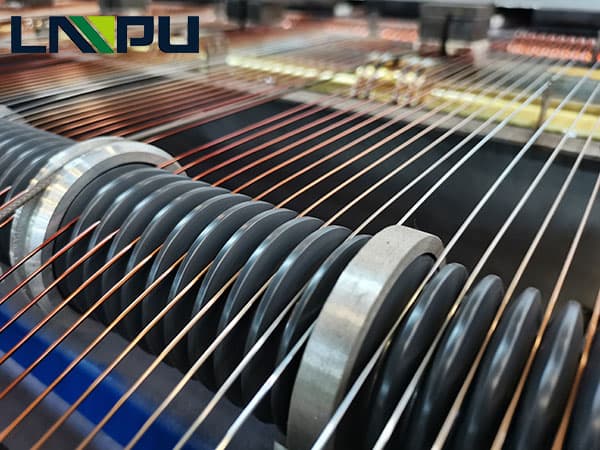

The winding is the key component of the electric motor for electromagnetic energy conversion and transmission, so as to realize the conversion of electrical energy into mechanical energy. The winding is the most important part of the motor, and the choice of Enameled Copper/Aluminum Wire For Motor is also very important

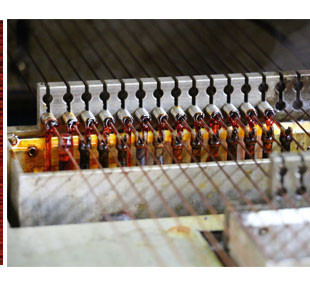

Motor data (phase number, number of stages, number of turns, wire diameter, slot number, winding form, coil span, stator core length, inner diameter, outer diameter) Winding: According to the number of slots, the number of stages, determine the number of coils The number of coils, the number of turns determine the number of turns of each coil, and the inner diameter and outer diameter of the iron core determine the circumference of the coil.

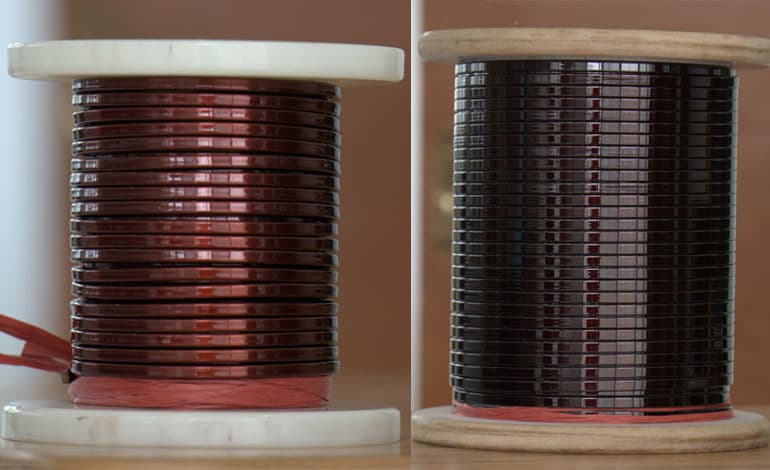

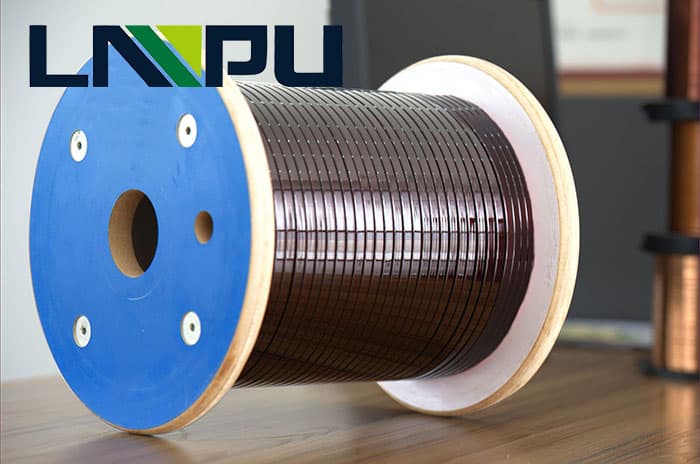

The wire diameter of the motor winding is accurately calculated from the power and voltage core size and other data. The national standard motor has a fixed wire diameter data. However, when the original wire gauge is not available during repair or factory manufacturing, it can be wound with a smaller diameter than the original wire. It must be ensured that the cross-sectional area is equivalent to the original wire diameter, and it can be used as long as the slot full rate allows the cross-sectional area to be equivalent.