Home » enameled aluminum wire » Enameled Aluminum Wire VS Aluminum Wire

Enameled Aluminum Wire VS Aluminum Wire

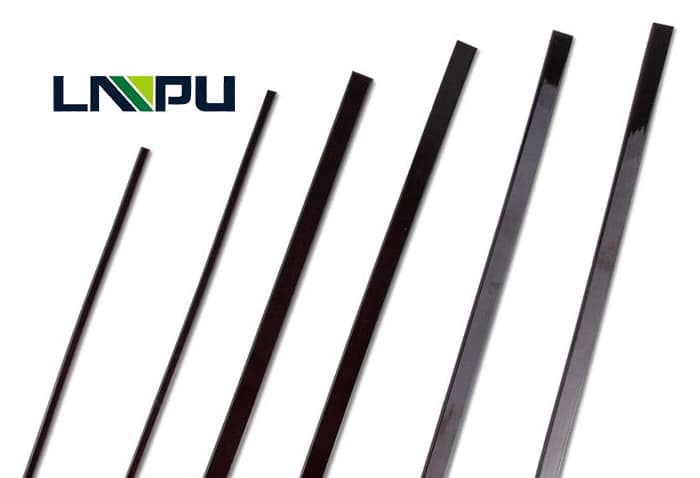

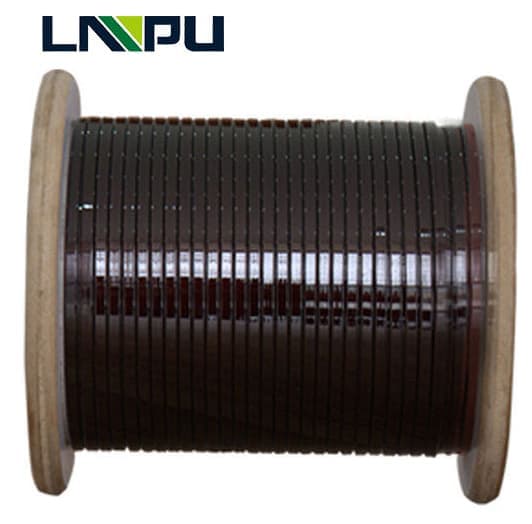

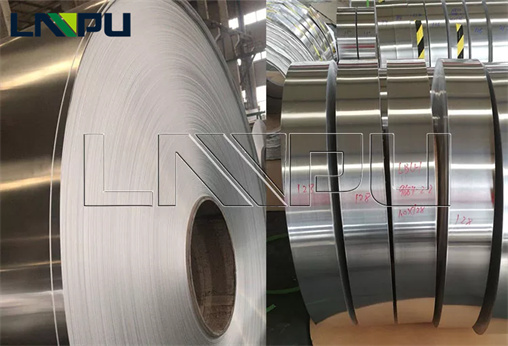

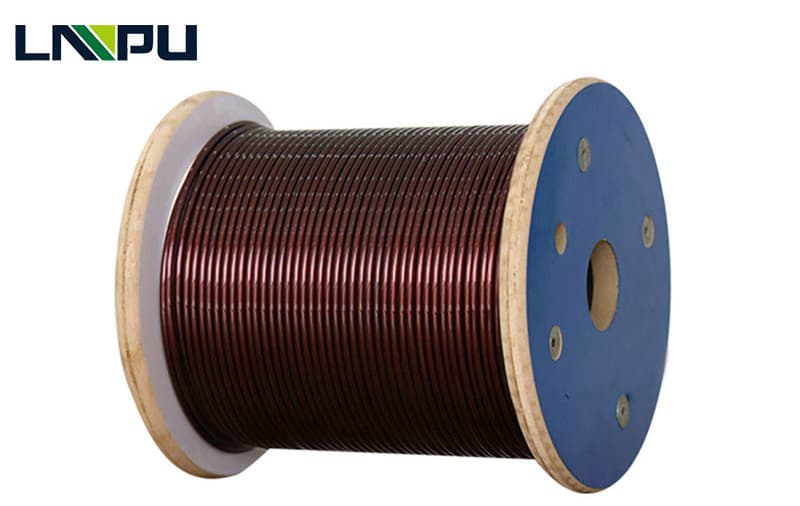

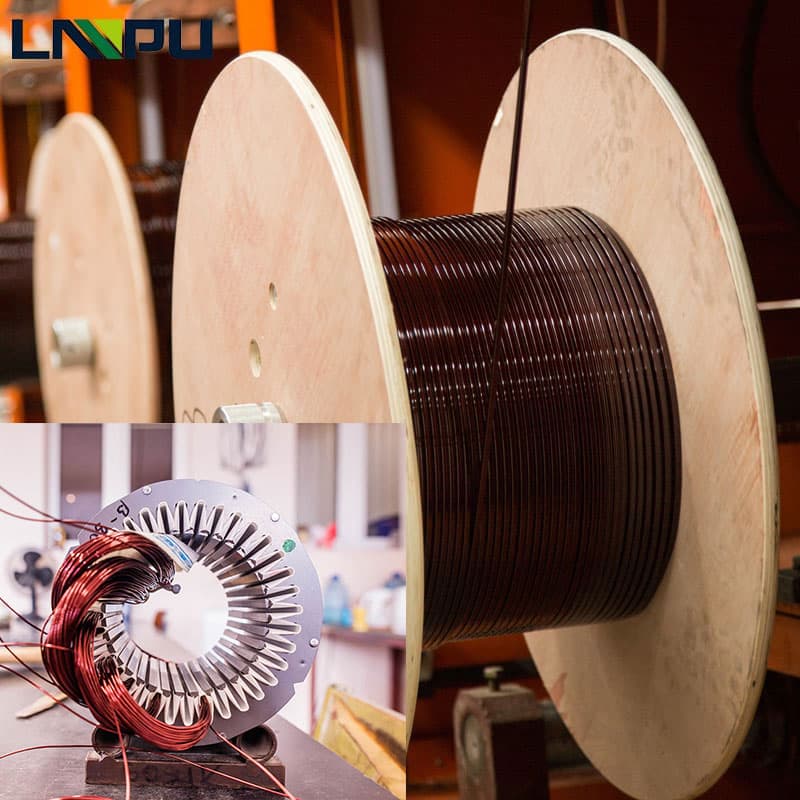

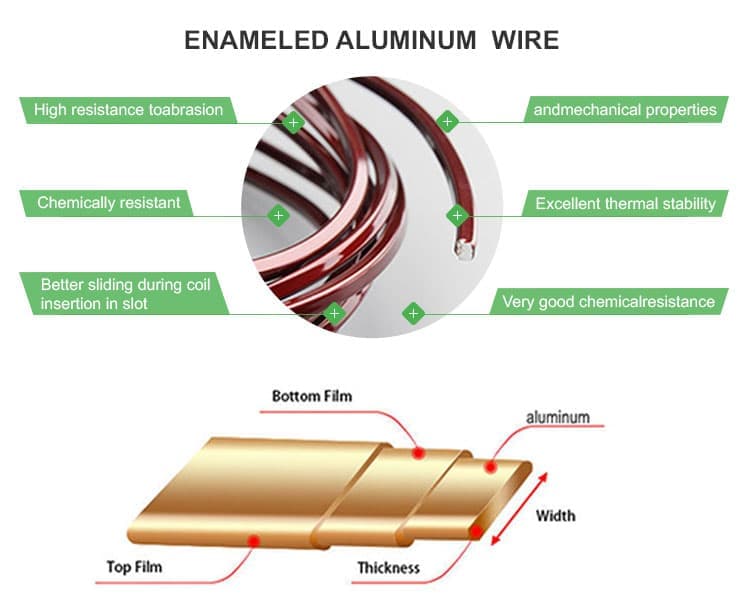

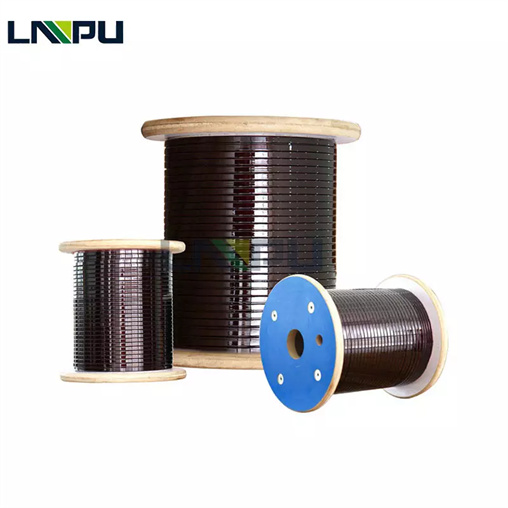

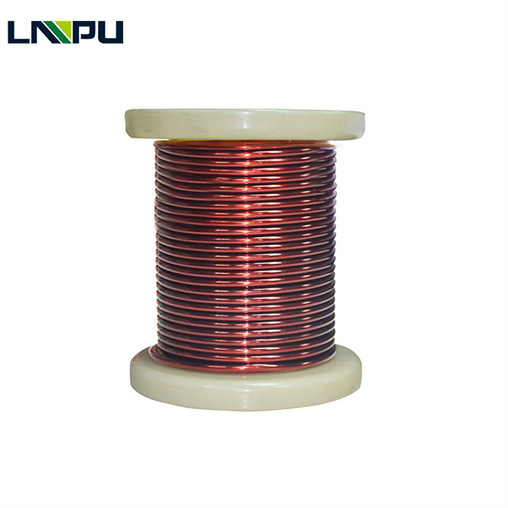

Enameled aluminum wire is a main type of winding wire. It consists of two parts: conductor and insulating layer. After bare wire is annealed and softened, it is baked and baked. The aluminum Wire is not insulated, and the surface of the enamelled aluminum wire has an insulating paint film that can be directly used.

Contact US

Get Price

Share:

Content

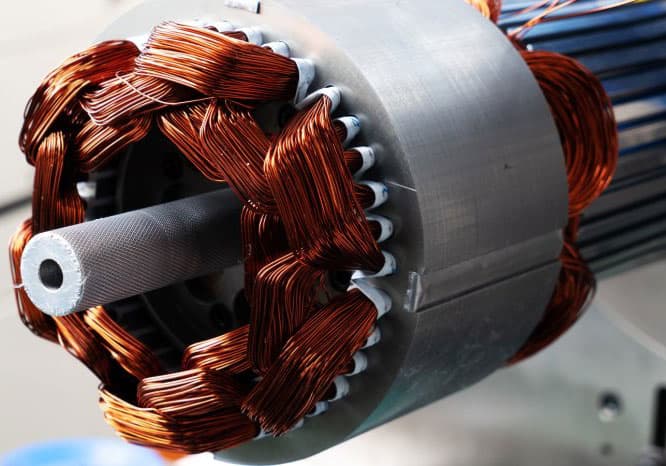

Enamelled aluminum wire has excellent high temperature resistance, mechanical properties, electrical and chemical properties and excellent freeze resistance. It is suitable for long-term work in 200 ¡ã C refrigeration equipment and chemically eroded electrical equipment, dry-type transformers, oil-immersed Transformer and epoxy casting transformers, iron remover, electromagnet and other mechanical and electrical equipment.

Inquiry

More enameled aluminum wire