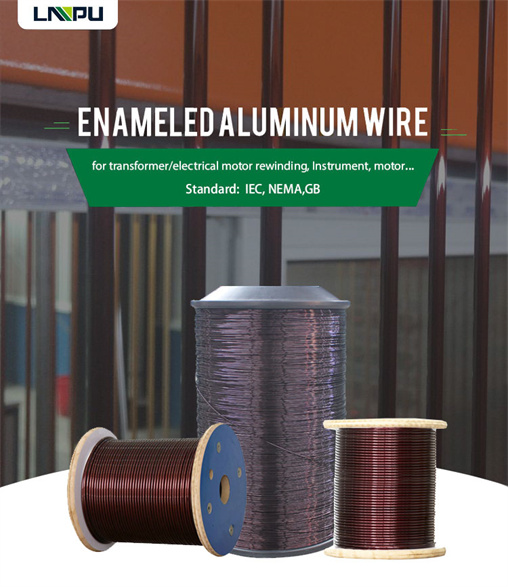

Enameled Aluminum Wire On The Market

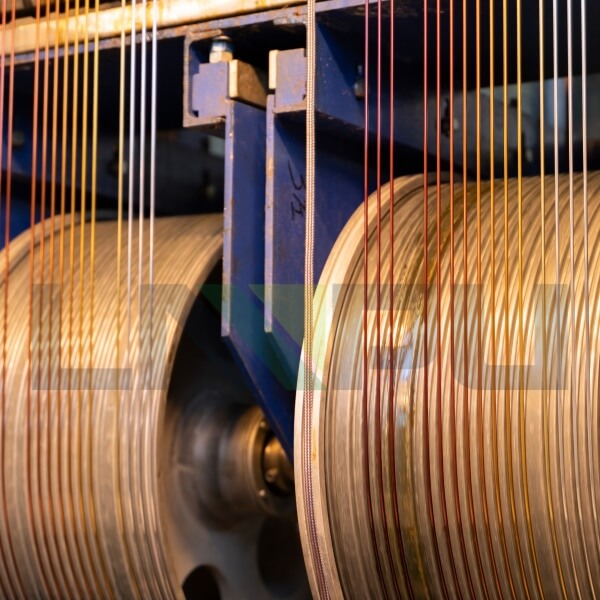

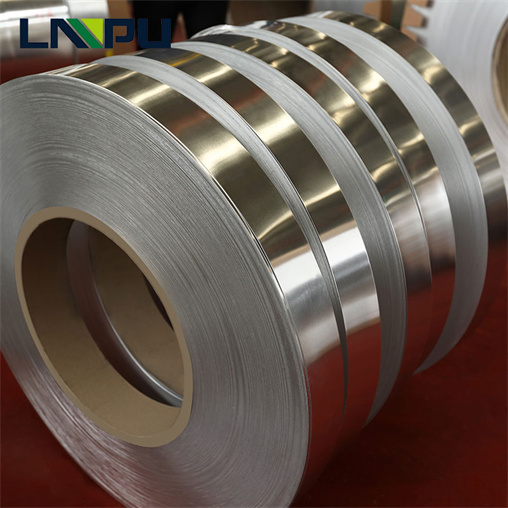

With the transformer and motors developping, the Enameled Aluminum Wire On The Market is used more and more, expecially the unstable price of copper.

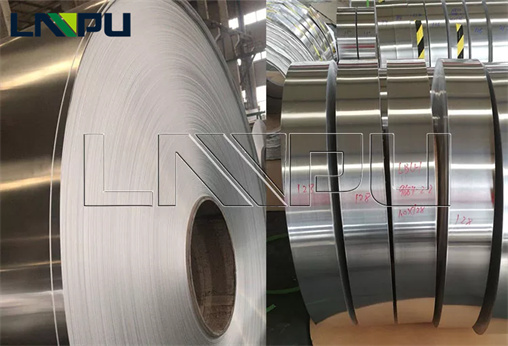

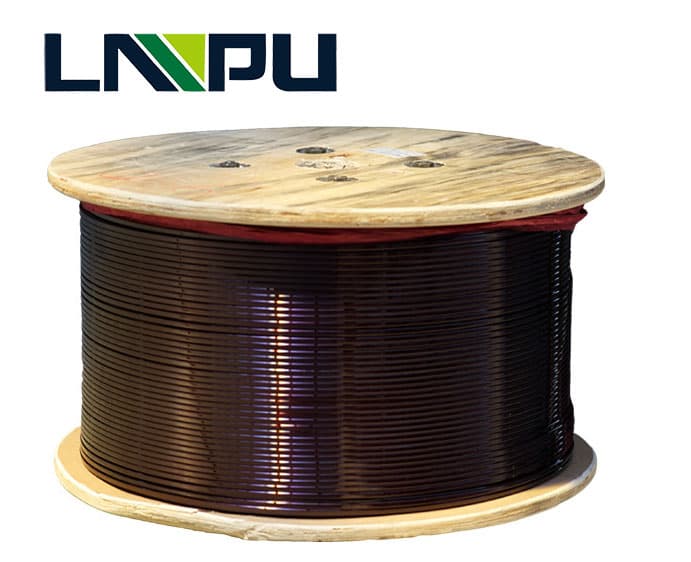

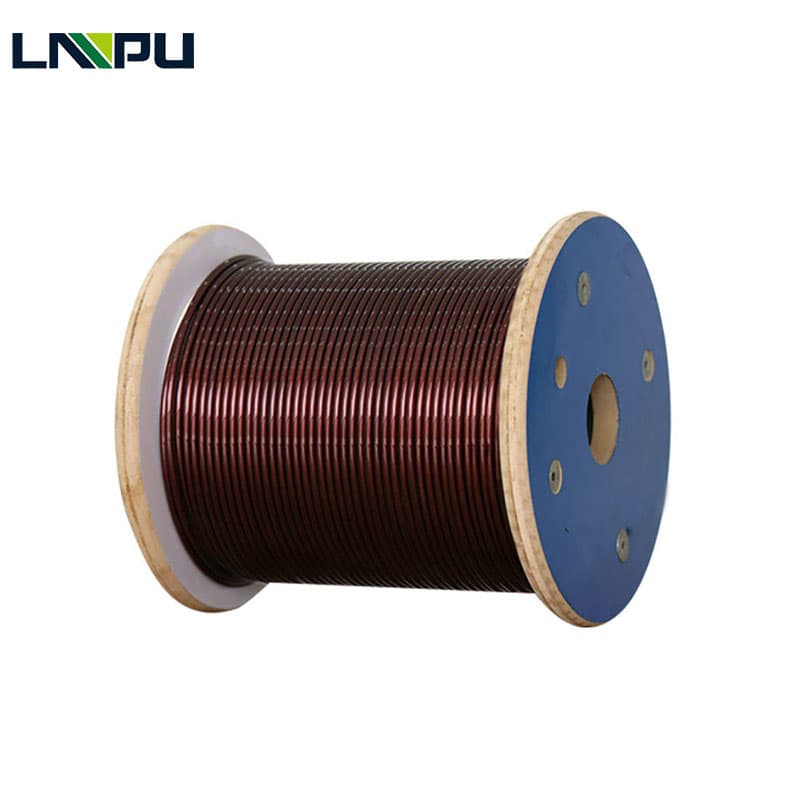

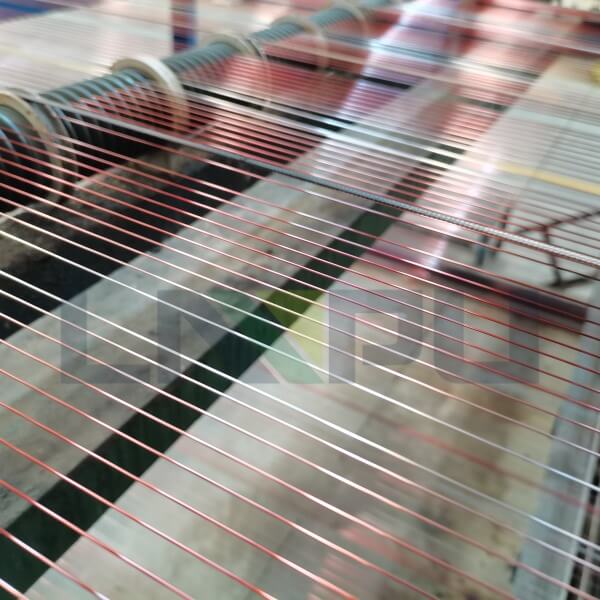

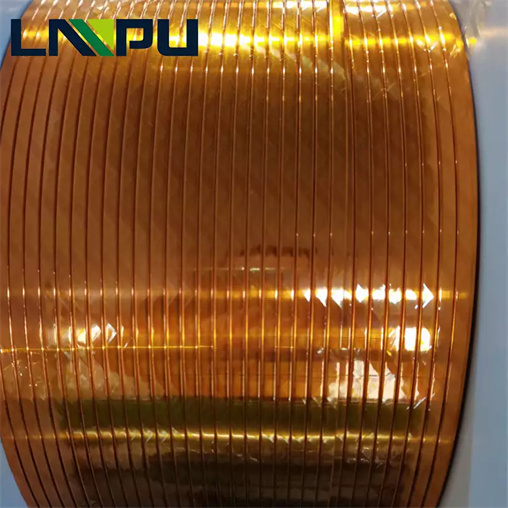

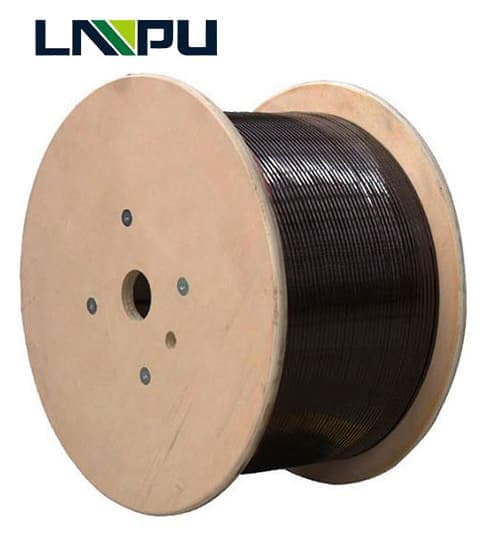

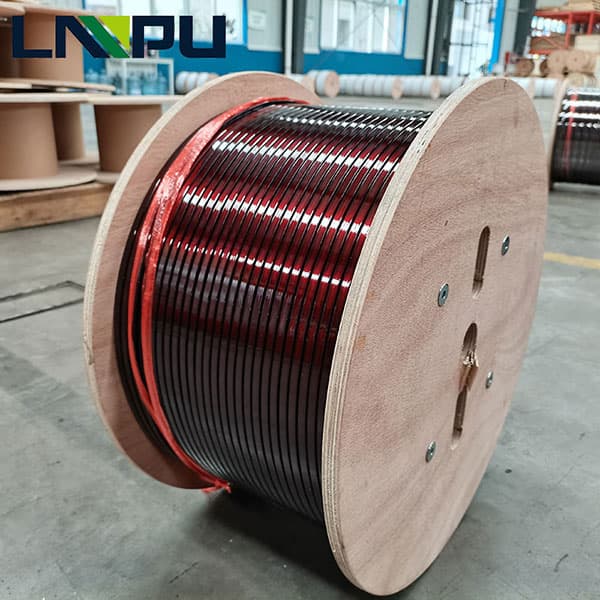

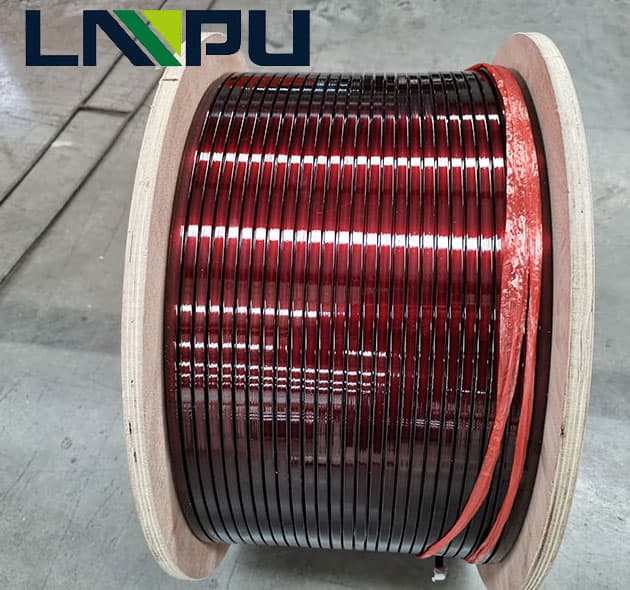

Enameled Aluminum Wire Type: rectangular and round type

Certificate: UL

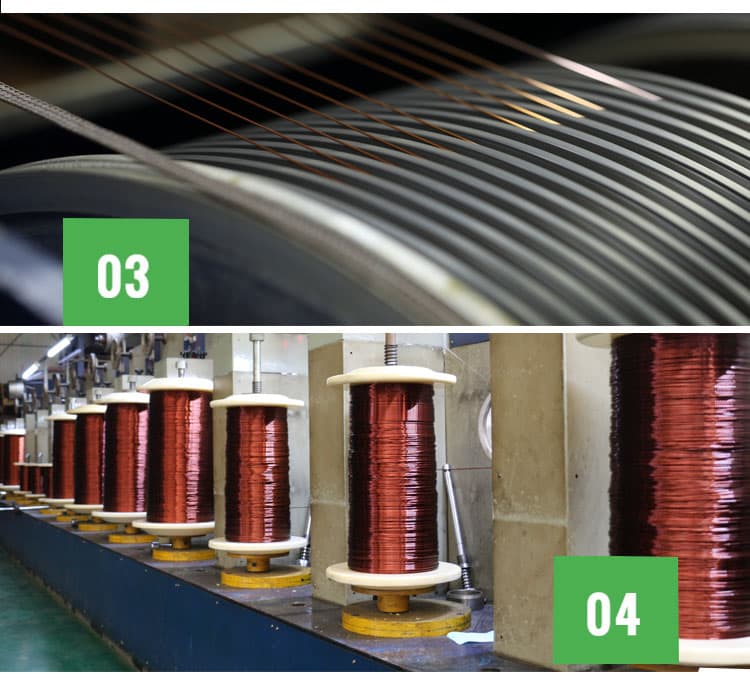

In recent years, with the sharp rise of copper prices and the instability of the current state, many customers have been greatly challenged by material costs. As a result, the development of enameled aluminum wire has been accelerated, which has attracted more and more attention.

enameled aluminum wire has been widely used in Asia such as Europe, the United States, and South Korea. In the 1990s, European and American countries widely used aluminum enameled wires. Before China was difficult to recover copper resources in the 1970s, they used aluminum enameled wires in the fields of cables, power transformers, and motors. From this point of view, the use of aluminum enameled wire should be no problem, but there are abundant copper resources, and the price of copper and aluminum is not much different. People began to use copper enameled wire and achieved rapid development in a short period of time. However, with the volatility of copper prices and cost pressures, aluminum has surfaced and developed rapidly.

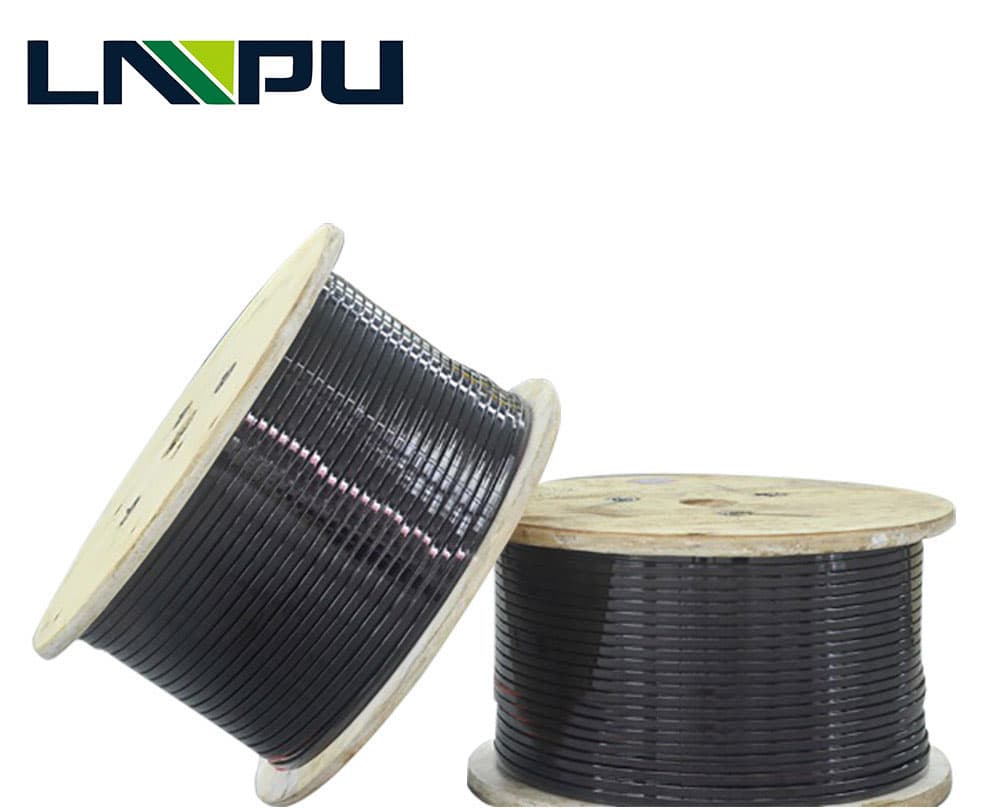

When it comes to using aluminum instead of copper, some customers will encounter the concept that using aluminum instead of copper is the opposite technology. In fact, this is incorrect. Enameled aluminum wires have been used in Europe and the United States. The International Electrotechnical Commission (IEC) and other international standards bodies have also formulated corresponding technical standards for enameled aluminum wires (IEC60317-0-3, IEC60317-25). , NEMA-1000, etc.) also shows that the use of enameled aluminum wire is technically mature. Therefore, some customers do not have to worry too much when using enameled aluminum wire. However, we must also correctly understand the use of enameled aluminum wire, which is different from copper enameled wire, especially its welding problem, which really plagues many customers. This also limited the development and use of enameled aluminum wire, but through unremitting efforts, the problem has been resolved by different customers. Some customers use crimping and riveting, some use flux welding, and some use argon arc welding. Different methods are adopted according to different products. In short, we will develop a good welding solution. And there are different types of enameled aluminum wire, including Rectangular Enameled Aluminum Wire.

With the further deepening of understanding of enameled aluminum wire, better use of technology, the trend of replacing copper enameled wire with aluminum has been irreversible and will be further expanded. As long as the design is reasonable and used correctly, the use of aluminum will be more extensive.