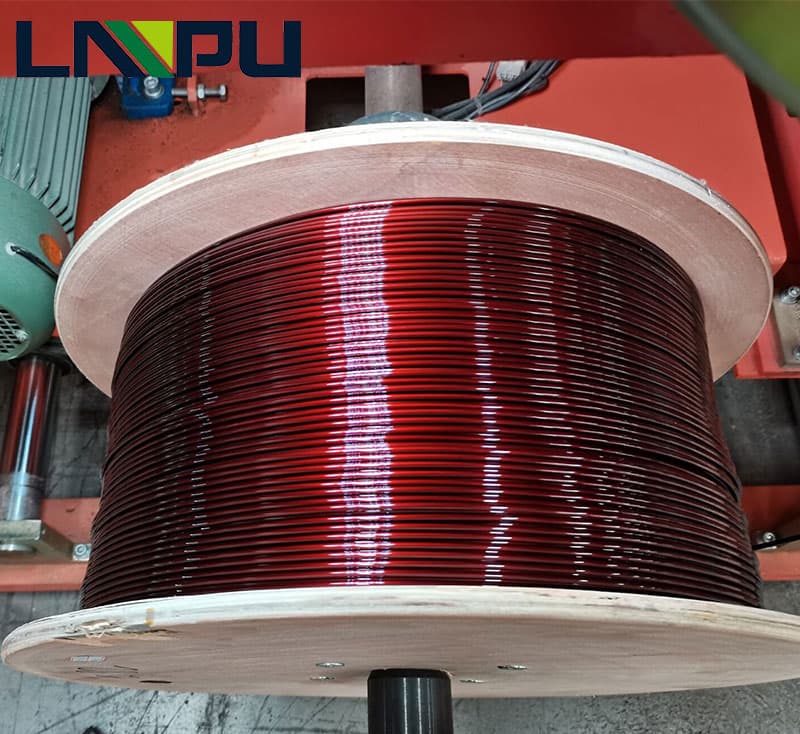

Enamel-covered wire characteristic

1. Polyester enameled wire (P.E.W.)

Polyester enamel-covered wire is made of heat-resistant Terephthalic Polyester resin as the main grease as the insulating film and baked on the conductor. Its characteristics are as follows:

¡ñThe heat resistance is superior to synthetic tree (P.V.F.) enameled wire and U.E.W. enameled wire.

¡ñExcellent chemical resistance (except alkaline) and solvent resistance.

¡ñThe mechanical strength is comparable to synthetic resin (P.V.F.).

¡ñThe force rate and dielectric rate are comparable to U.E.W. enameled wire.

¡ñAlkali resistance and moisture resistance are better than synthetic resin enameled wire (P.V.F).

2. Polyurethane lacquer (U.E.W.)

Polyurethane enamel package is made of Polyure thane resin as the main grease as the insulating film, and baking varnish on the conductor. Its biggest feature is that the film can be dissolved in a short time when the film is above 300 ¡æ, so it can be soldered without peeling. Its characteristics are as follows:

¡ñThe heat resistance is superior to synthetic tree (P.V.F.) enameled wire.

¡ñBecause it can be tinned without peeling, it can improve work efficiency.

¡ñAlcohol-resistant series solvents are slightly worse than general enameled wires, but there is no effect on the application.

3. Polyimide polyester E.I.W. enameled wire

The coating is Polyester-imide resin with high thermal stability and high dielectric strength. Its characteristics are as follows:

¡ñGood thermal shock resistance.

¡ñGood abrasion resistance and flexibility.

¡ñGood heat resistance and chemical resistance.

¡ñCold resistant R-12 and R-22.

4. Polyimide amide enameled wire (AI.W)

The coating is made of Polyamide-imide resin, which has excellent heat stability. Its characteristics are as follows:

¡ñExcellent heat resistance.

¡ñGood abrasion resistance.

¡ñGood chemical resistance.

¡ñCold resistant R-12 and R-22.

5. Self-fusing polyurethane enameled wire (SBW)

Self-melting polyurethane enameled wire is made of U.E.W enameled wire plus a layer of thermoplastic film. Its characteristics are as follows:

¡ñHave all the characteristics of U.E.W. enameled wire.

¡ñThe heating and drying treatment can save COIL vacuum impregnation time, improve work efficiency and reduce cost.

¡ñIt can be adhered to the interlayer paper to prevent slippage between the lines.

6. Oil-based resin enameled wire (EW)

Oil-based resin enameled wire is the earliest commonly used enameled wire, which is made of natural resin and dry oil as the insulating film, which is baked on the conductor according to the specified thickness. Its characteristics are as follows:

¡ñIn the enameled wire, the volume is the smallest, which can make the COIL lighter. It saves the use of materials and reduces the cost.

¡ñExcellent water resistance, moisture resistance, and short-term heat load.

¡ñDue to solvent resistance and poor oil resistance, it is necessary to choose a solvent when immersing in oil.