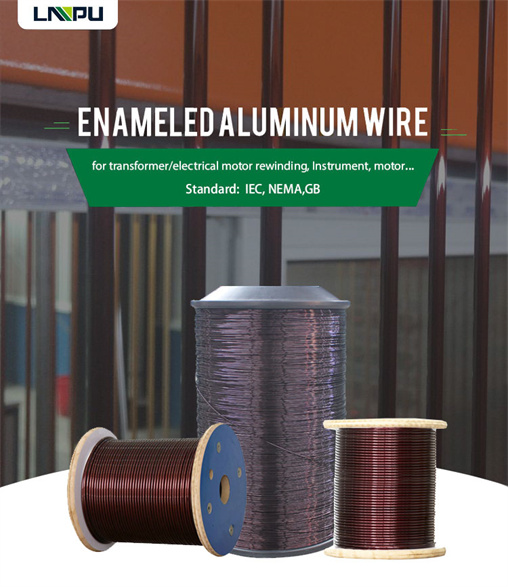

Electric motor winding materials aluminum winding wire

Aluminum is an excellent electrical conductor, and consequently, most electric motor manufacturers offer it as an option in their motor designs. So why isn¡¯t it used more commonly in motor applications? There are economic reasons and performance reasons that limit aluminum¡¯s usefulness in electric motors.

Detailed Description:

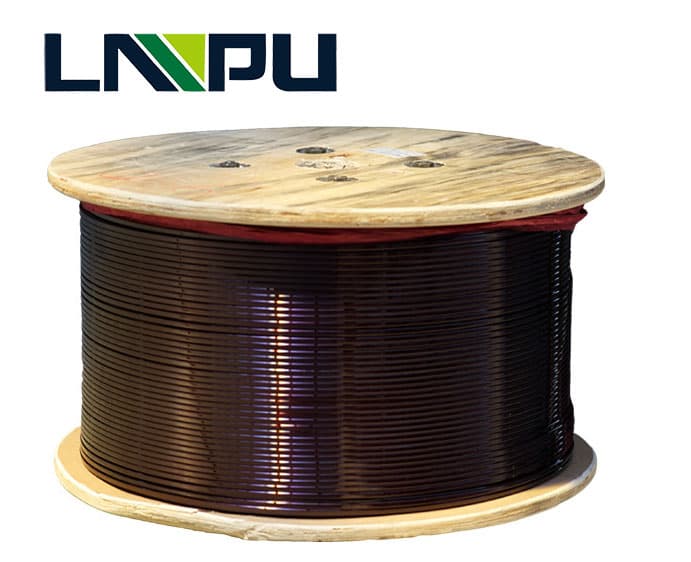

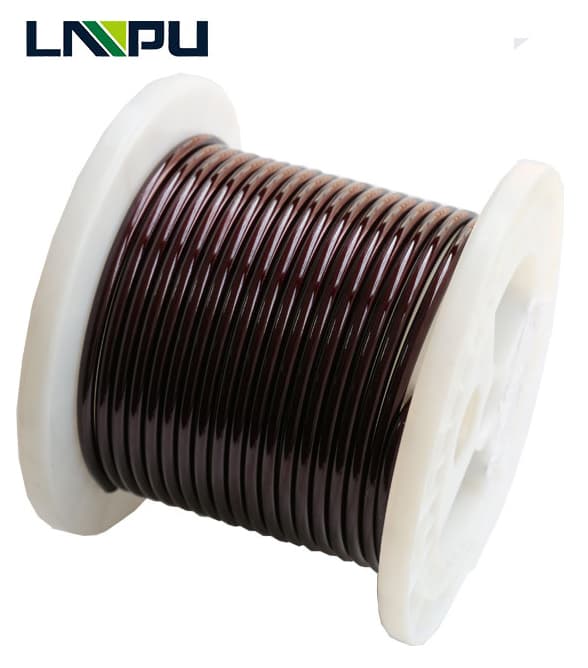

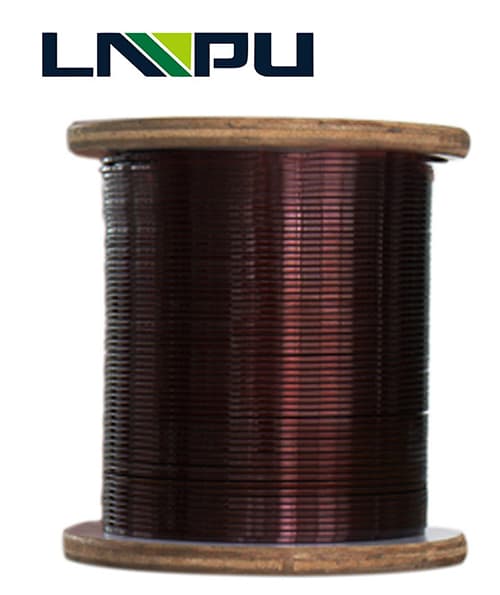

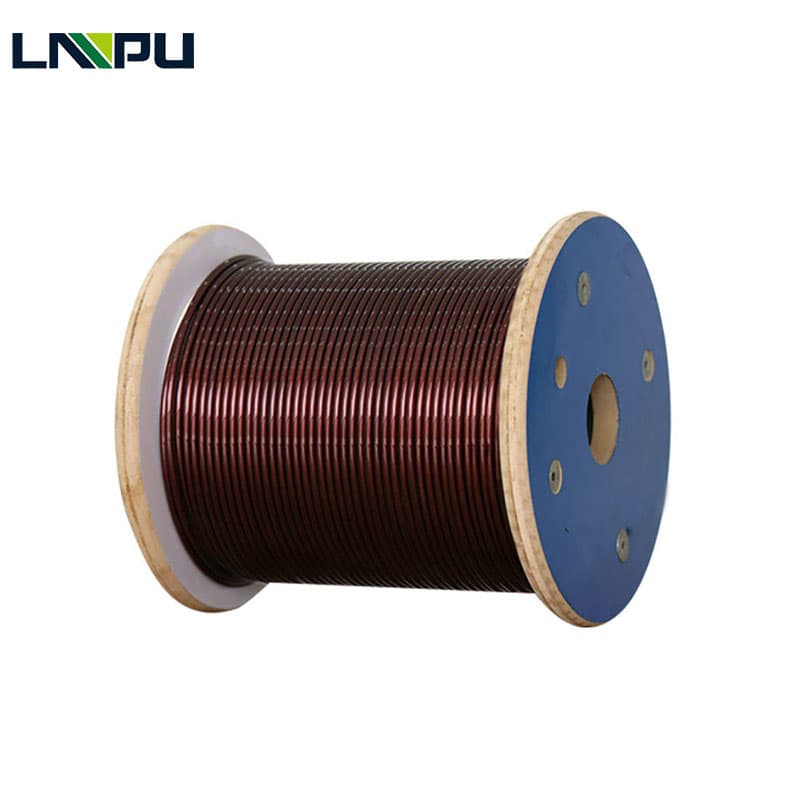

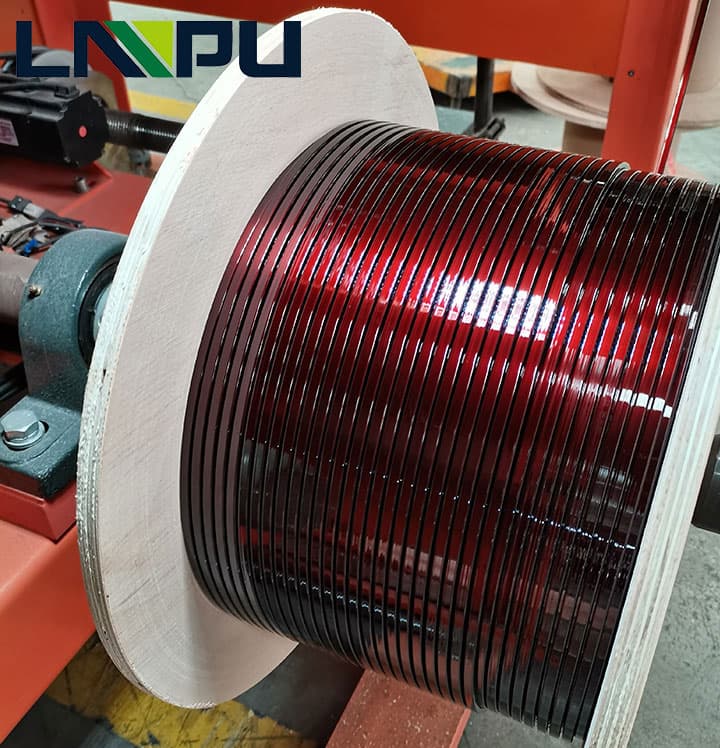

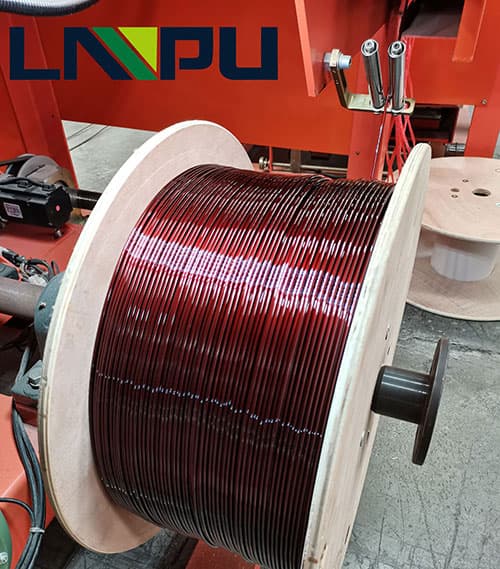

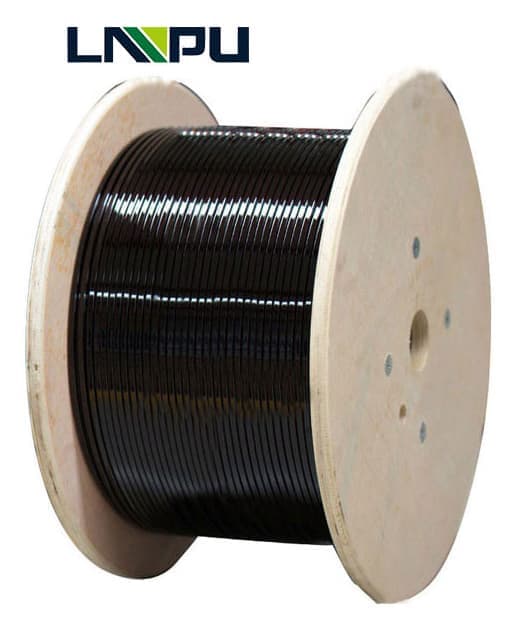

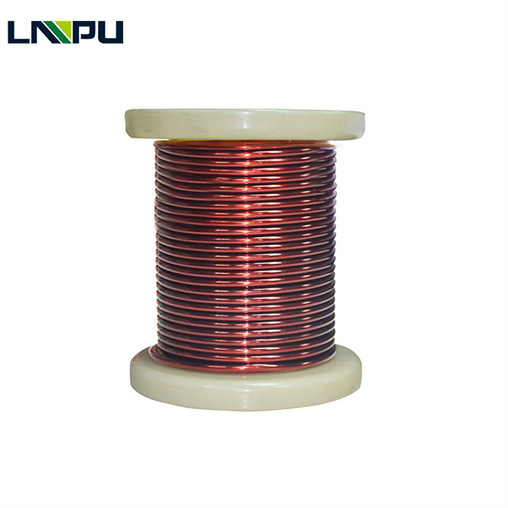

Product : Enameled aluminum winding wire

Diameter : Enameled Aluminum winding wire:0.12-6.5mm

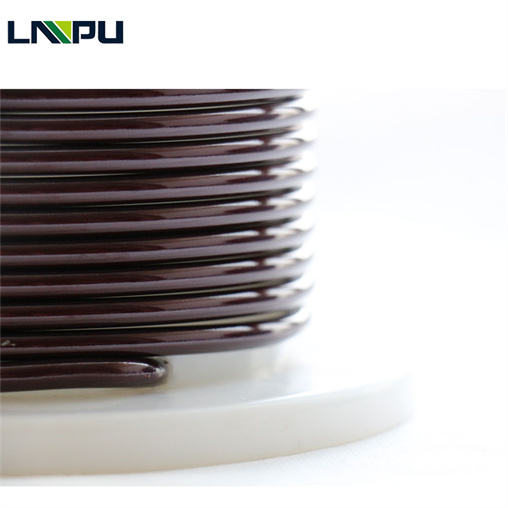

Insulation material : Polyester,Polyurethane,Polyester-imide,Enameled;

Grade : 130,155,180,200,220

Insulationg tickness : 0.007-0.14mm

Core number : one

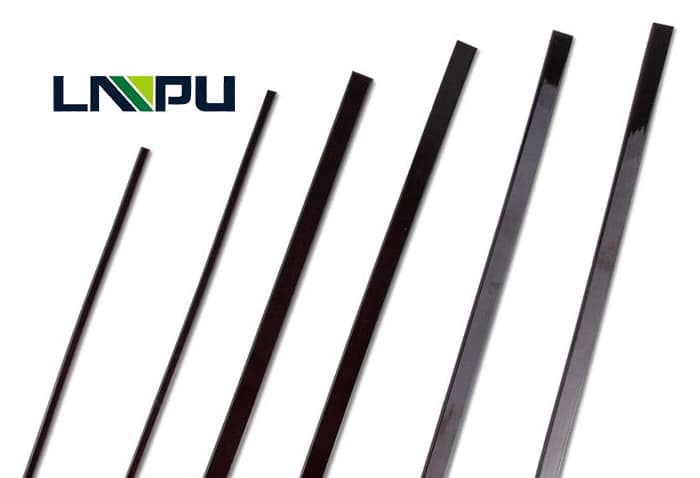

Shape materials : Round,rectangular;

Elongation : >15%

Tensile strength : 130-150Mpa

Paint : 1730,1736,1745,1754

Packing : Carton

Standard: IEC, NEMA, GB, JIS

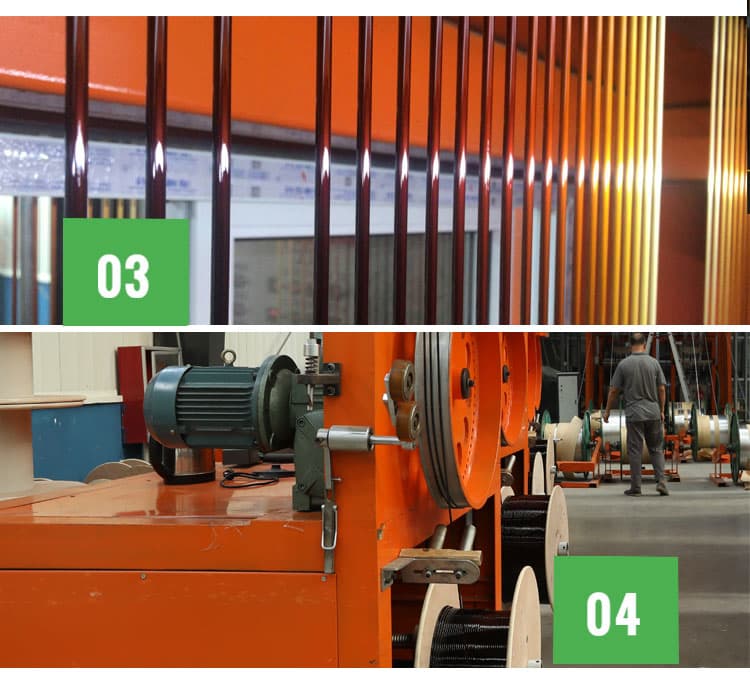

Certification: ISO9001, ISO14001, UL, RoHS, Reach

Advantages:

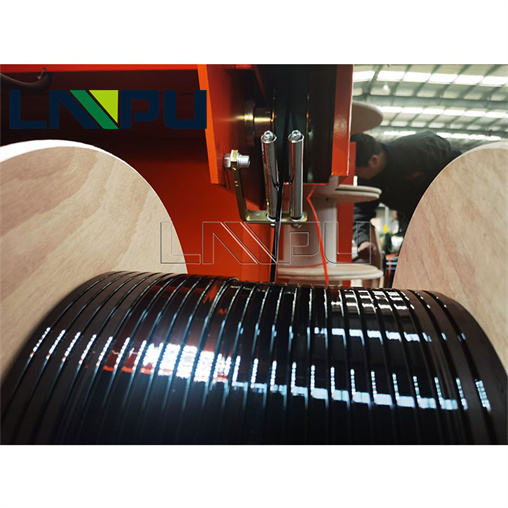

1. Compared with the copper enameled wire, enameled Aluminum winding wire is easier to winding, also there is asolid oxide film on the surface of enameled Aluminum winding wire, which make it has a good insulating effect, a long life.

2. Due to the good insulating effect of aluminum film layer, it’s heat-resistant temperature can be 20 degrees higher than the copper wire;

3. The greatest benefit of using aluminum is that it is 1 / 3 lighter than copper which significantly lower the production costs, second it can attach to the solids easily, and third it can also reduce the freight and transportation during the operation.

Main Export Markets:

Eastern Europe;

North America;

Mid East/Africa;

Central/South America;

Asia;

Western Europe;

Australasia;

Application feilds:

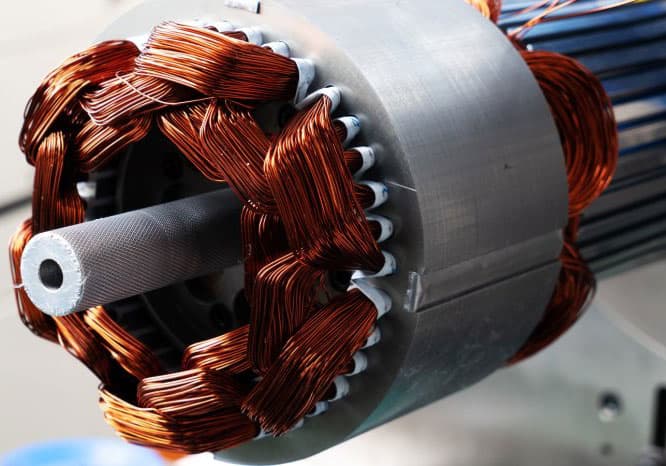

1.Used in production of light weight, relatively high conductivity, heat resistance and good windings, especially the transmission of high frequency signal windings;

2.Used in magnet wires of high-frequency voltage devices, common transformers, inductance coils, electromotors, household appliance, electrical tools and micromotors;

3.Used in ballasts, automotive electronics, refrigerator, microwave oven, air conditioner compress, communication tools, instruments, generators, electromotors, etc.