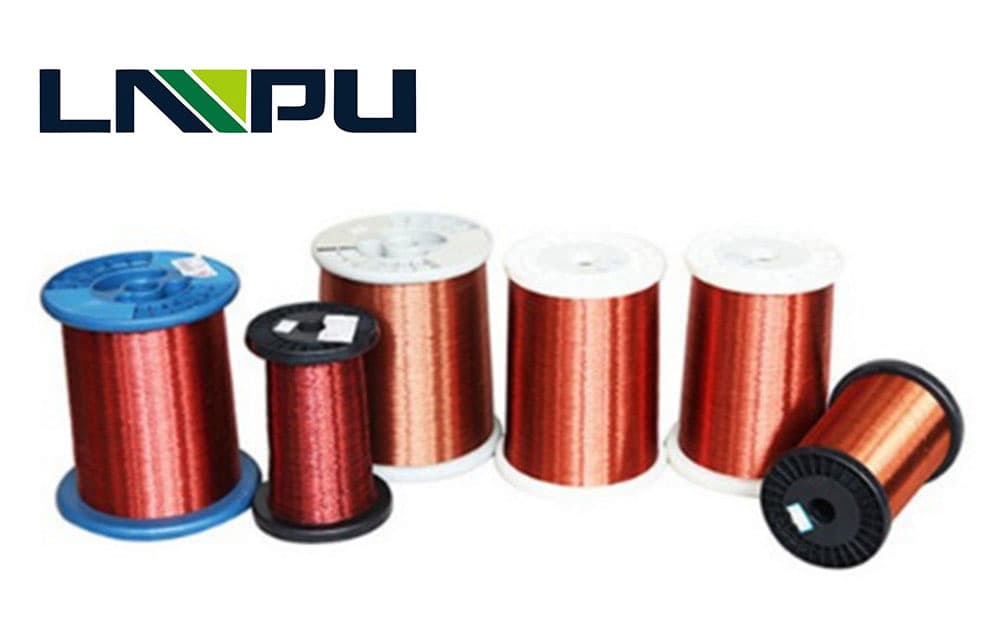

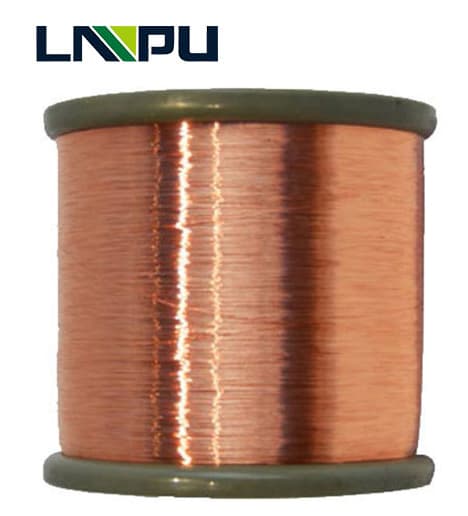

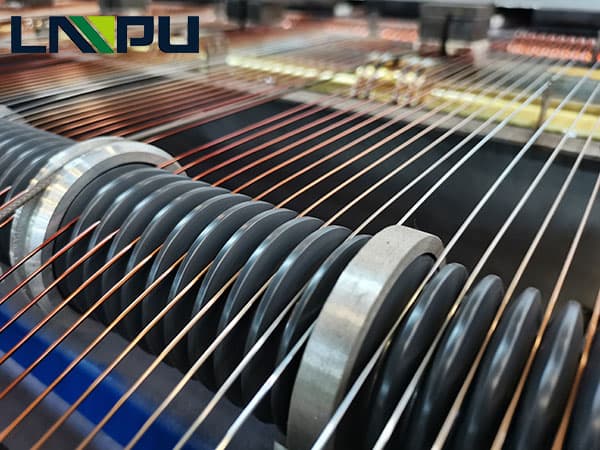

ECCA Enameled Copper Clad Aluminum Magnet Wire

Application:1. High-frequency transformers, ordinary transformers; 2. Inductances, electromagnetic coils; 3. Motors, including household motors, various micro motors, compressors and other motors with high environmental requirements; 4. Special electromagnetics for audio coils and optical drives Wire; 5. Electromagnetic wire for display deflection coil; 6. Electromagnetic wire for degaussing coil;

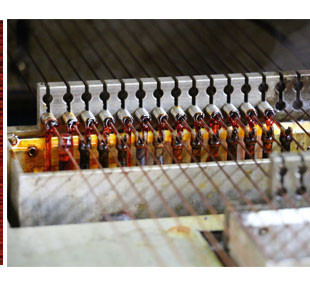

Materials and manufacturing

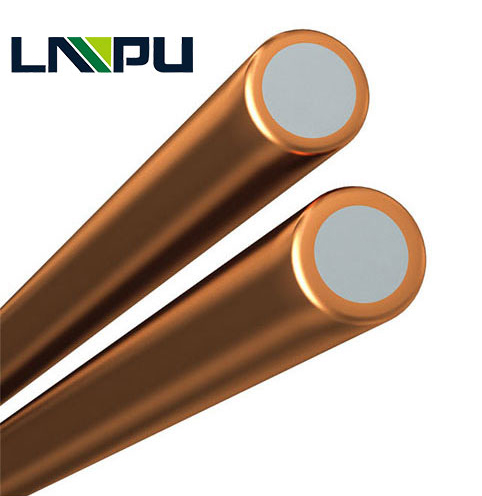

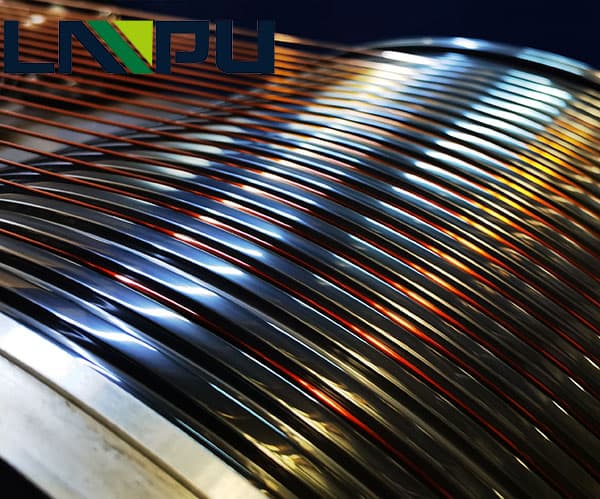

The copper-clad aluminum wire should be composed of an aluminum core and a continuous copper layer covering, and the copper layer should be fully combined with the core wire. The quality of copper clad aluminum wire shall meet the requirements of this standard.

Size quality

The size of copper clad aluminum wire should be expressed by wire diameter in inches, and the decimal point is accurate to 0.0001 inch (0.003 mm). For wire diameters below 0.0100 inches (0.254 mm), the wire diameter change should not be greater than ¡À0.0001 inches (¡À0.003 mm) of the specified diameter, and for wire diameters equal to and greater than 0.01130 inches (0.254 mm), the wire diameter change should not be greater than The specified diameter is ¡À1%, and the size is accurate to 0.0001 inch (0.003 mm).

Product quality appearance

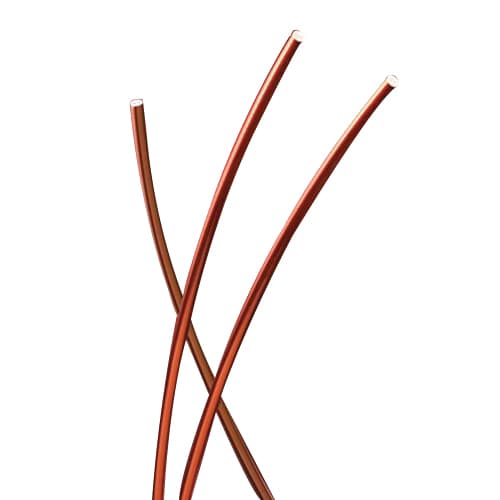

The copper clad aluminum wire should be free of dents, cracks, exposed aluminum or other defects that are inconsistent with good industrial practice.

For copper-clad aluminum wires with a diameter of 0.0720 inches (1.829mm) and above, the surface finish inspection should be performed with the naked eye (normal glasses are also possible). For copper-clad aluminum wire with a diameter less than 0.0720 inches, the surface finish inspection should be carried out under the condition that the magnification does not exceed 10 times.