Dry-type transformer

Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminal CNC machinery equipment and other places. Simply put, dry-type transformers refer to transformers whose cores and windings are not immersed in insulating oil.

Cooling methods are divided into natural air cooling (AN) and forced air cooling (AF). When natural air cooling, the transformer can run continuously for a long time under the rated capacity. When forced air cooling, the output capacity of the transformer can be increased by 50%. It is suitable for intermittent overload operation or emergency accident overload operation; due to the large increase in load loss and impedance voltage during overload, it is in a non-economic operation state, so it should not be kept in continuous overload operation for a long time

structure type

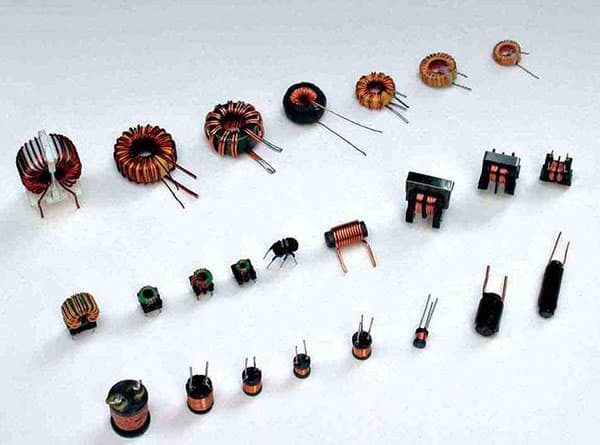

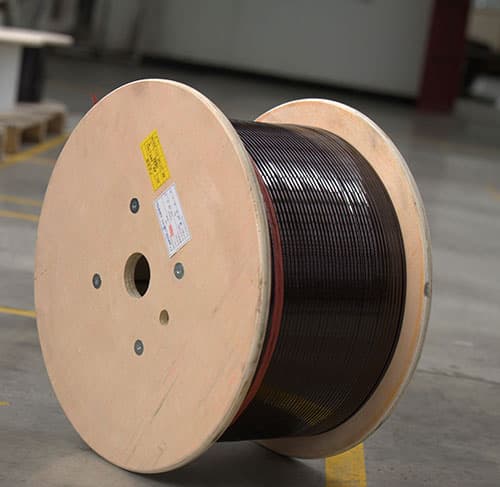

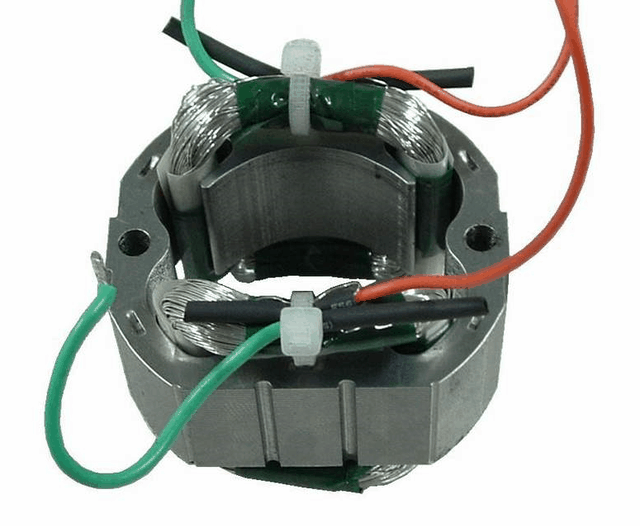

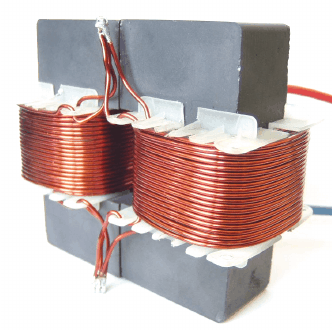

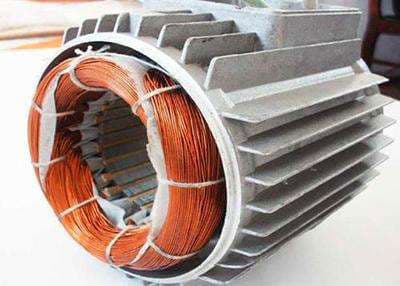

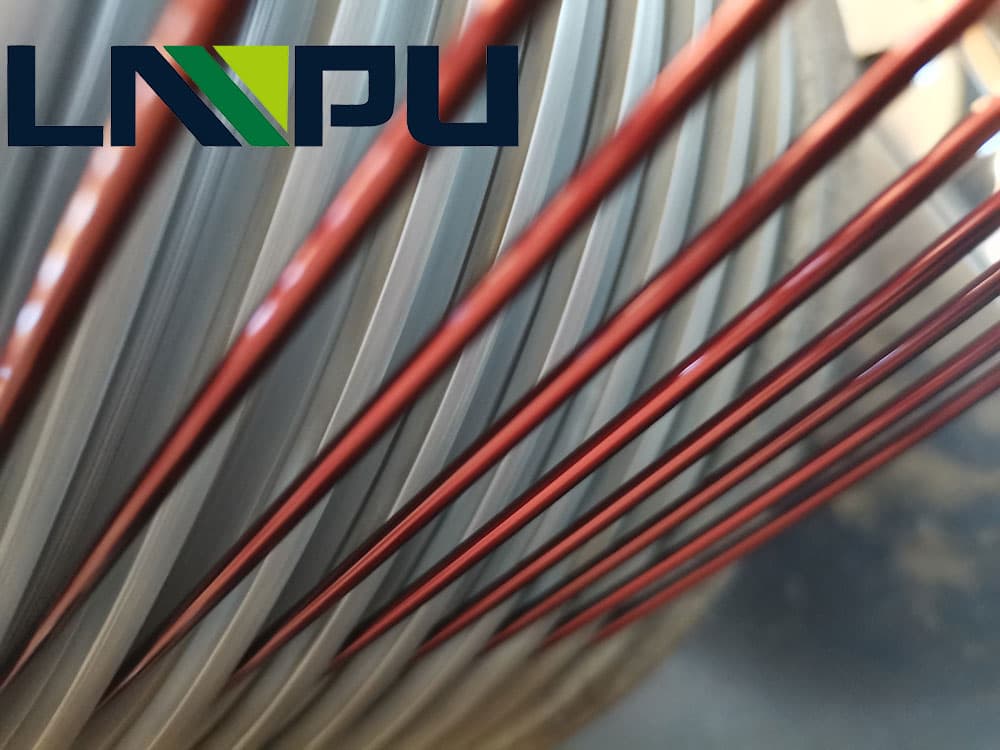

It is mainly composed of an iron core composed of silicon steel sheets and a coil which is composed of enameled copper wire or enameled aluminum wire and magnetic core, etc. cast by epoxy resin. An insulating tube is placed between the high and low voltage coils to increase electrical insulation, and the coil is supported and constrained by a spacer. Loose performance.

Construction performance:

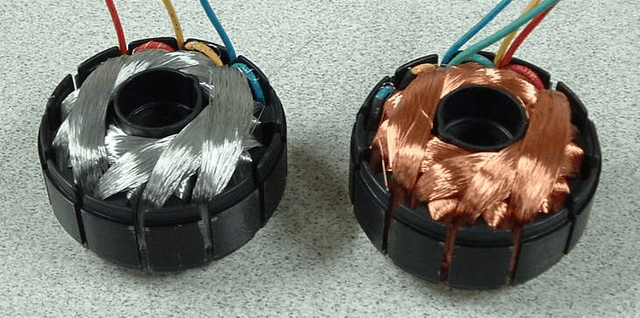

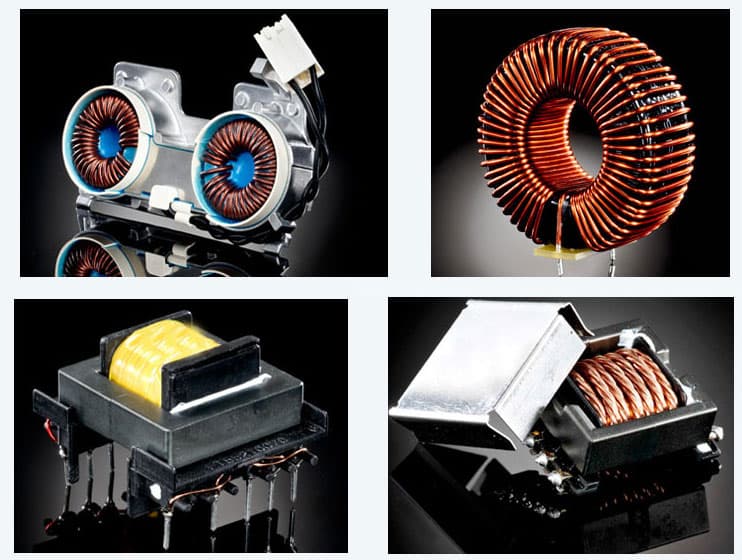

Solid insulation encapsulated winding

No enveloping winding

Winding: Of the two windings, the higher voltage is the high-voltage winding, and the lower one is the low-voltage winding.

From the relative position of the high and low voltage windings, the high voltage can be divided into concentric and overlapping types.

The concentric winding is simple and convenient to manufacture, and this structure is adopted.

Overlap type, mainly used for special transformers.