Does water quality affect the production of enameled wire?

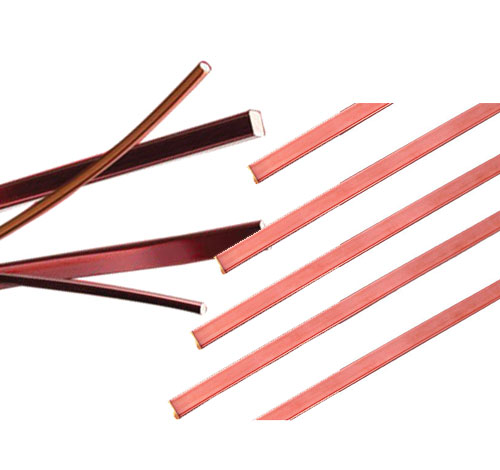

Enameled wire production water also has many uses, and similarly, the requirements for water quality are also different. According to the water quality requirements of the purpose of use, it can be divided into: annealing furnace sealing water, equipment cooling water, lubricant manufacturing water, etc.

1. Affect the quality of enameled wire.

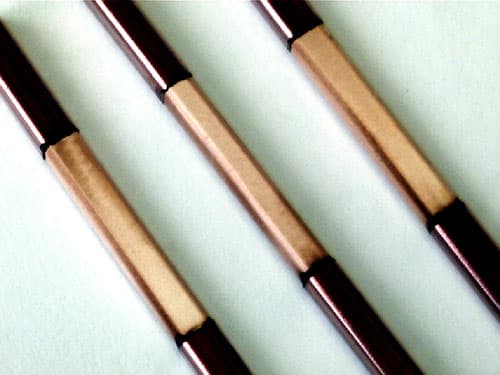

During the enameled wire production process, if the particles in the water remain on the copper wire, the surface of the copper wire will be uneven and small holes will occur; the pollution of ionic impurities will increase the surface charge density of the copper wire and cause the electrochemical performance of the oxide layer to decrease. Thereby affecting its parameters. During the stretching process, these impurities are adsorbed on the copper wire and diffuse into the copper wire, affecting the surface lubrication of the copper wire, resulting in uneven local resistance and easy breakdown. It is also caused by oil or organic substances in the water. The effect of painting and the poor adhesion of the paint film lead to the decrease of the pore insulation parameters. In particular, CL pollution will occur due to deliquesce. Dark spots occur in humid climates. This is the cause of enameled wire dark spots. Therefore, the paint film is perforated and moisture invades further, resulting in a decrease in the quality of the enameled wire. It is also the cause of the voltage drop.

2. The impact on mechanical parts.

We know that in the transmission process of mechanical equipment, in order to ensure that the equipment continues to work at high speeds and metal collisions, the equipment must be cooled. If the cooling water contains a lot of impurities, it will happen: equipment pollution, corrosion, scaling, salinization, pipeline mud, scale, and scale. The cooling effect of the device is reduced. Equipment damage is fast, maintenance pressure increases, and mechanical life is reduced, which will seriously affect the production power and economic benefits of the equipment.