Difference between electromagnetic wire and enameled wire

Enameled wire is a type of electromagnetic wire, usually refers to the insulation wire used to make coil or winding in electrical products. It is also called the winding wire.

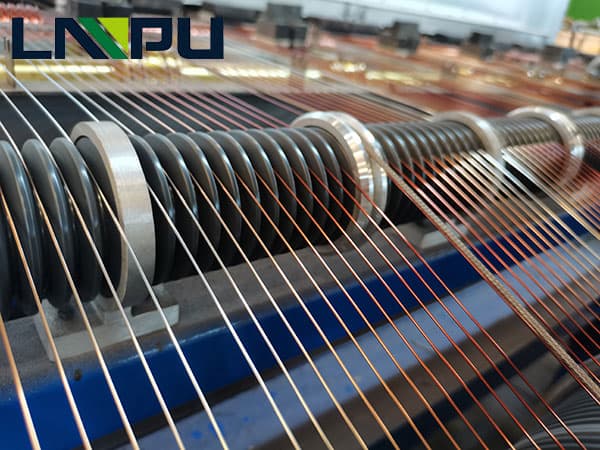

The electromagnetic wire must meet the requirements of various applications and manufacturing processes. The former includes its shape, specification, working at high temperature in short and long time, as well as the strong vibration and centrifugal force under high speed on certain occasions, resistance to corona and breakdown under high voltage, and chemical corrosion resistance in special atmospheres, and the requirements for tensile, bending and wear, as well as the requirements of drawing, bending and wear during winding and inlaying. Swelling and erosion during immersion and drying.

The electromagnetic wire can be classified according to its basic composition, conductor core and electrical insulation layer. It is usually divided into enameled wires,winding wires, enameled wrapping wires and inorganic insulated wires according to the insulation materials and manufacturing methods used in electrical insulation.

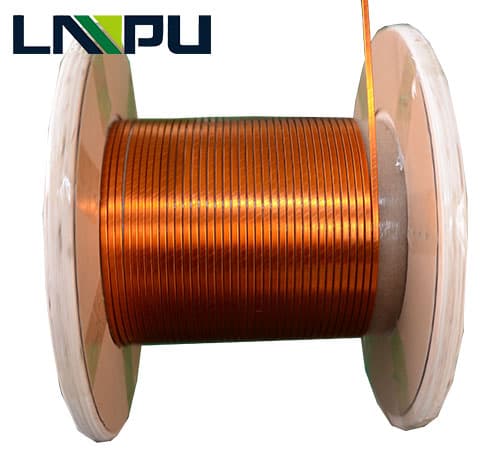

The enameled wire is coated with the corresponding paint solution outside the conductor, and then made by solvent evaporation and film solidification and cooling. The enameled wire can be divided into polyester enameled wire, polyester imide enameled wire, polyimide enameled wire, polyester imide / polyamide imide enameled wire, corona enamel line, and oil paint, acetal paint, polyurethane enameled wire, etc. Sometimes they are classified according to their special characteristics, such as self adhesive enameled wire, cold resistant enameled wire, etc.

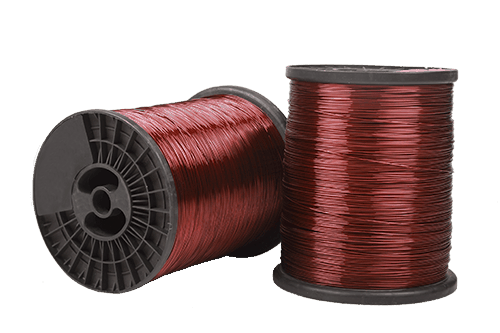

The earliest enameled wire is oil-based enameled wire, made of tung oil. The paint film has poor wear resistance and can not be directly used for manufacturing motor coils and windings. Later, polyvinyl formal enameled wire came out, its mechanical properties were greatly improved, it can be directly used for motor winding, and it is called high strength enameled wire.

With the development of weak current technology, a coil with self adhered enameled wire has been developed, which can obtain better integrity without impregnation and baking. But its mechanical strength is poor. It can only be used in micro motors and small motors. In addition, in order to avoid the trouble of removing the film before welding, the direct welding enameled wire has been developed. The coating can fall off at the high temperature stannum and make the copper wire easy to weld.

Due to the increasingly extensive application of enameled wire, the requirements are becoming stricter and stricter, and the composite enameled wire has been developed. The inner and outer coatings consist of different polymer materials, such as polyester imide / polyamide imide enameled wire.