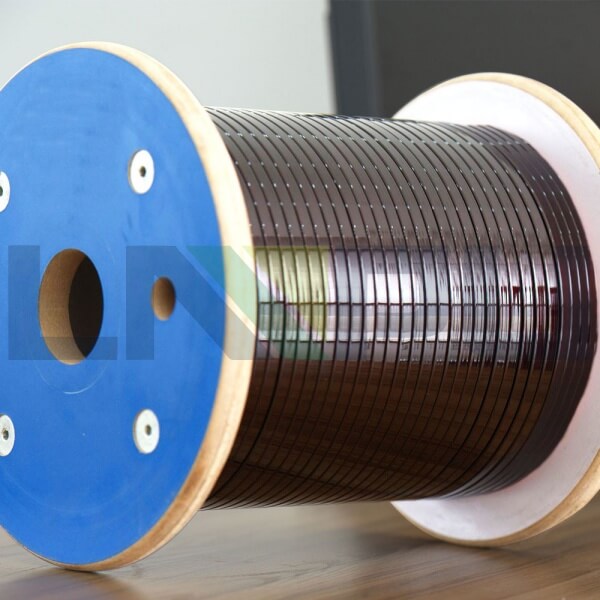

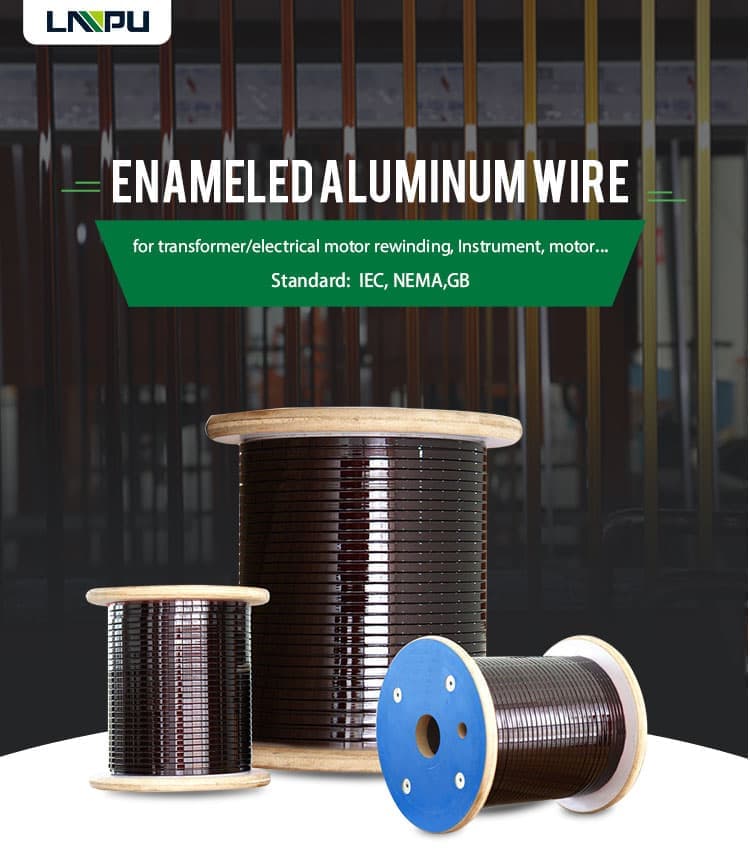

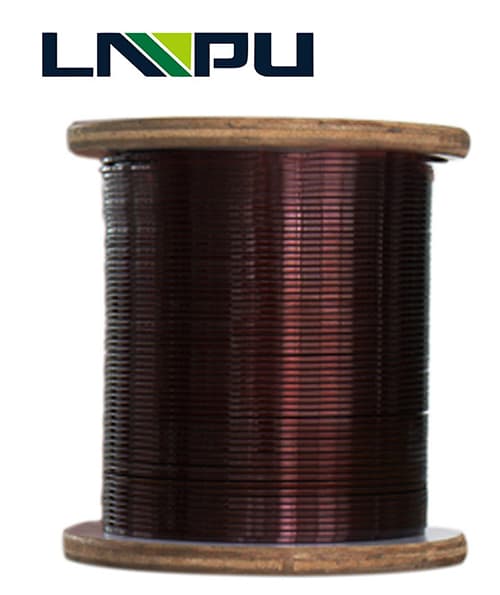

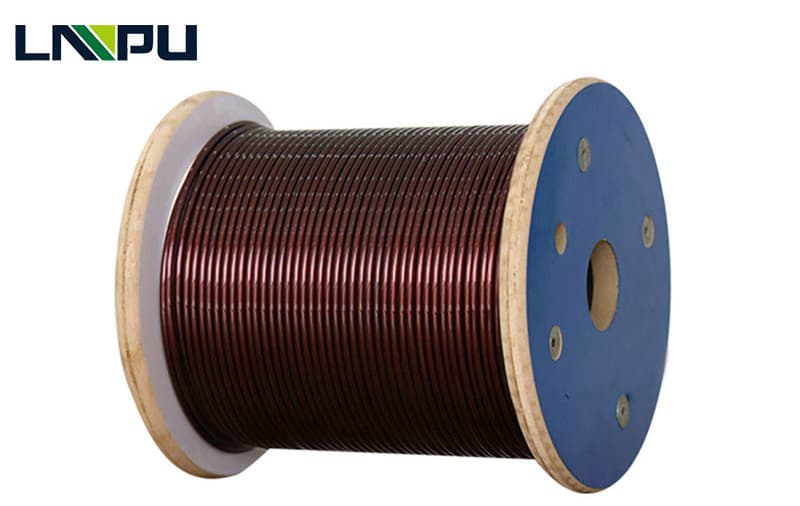

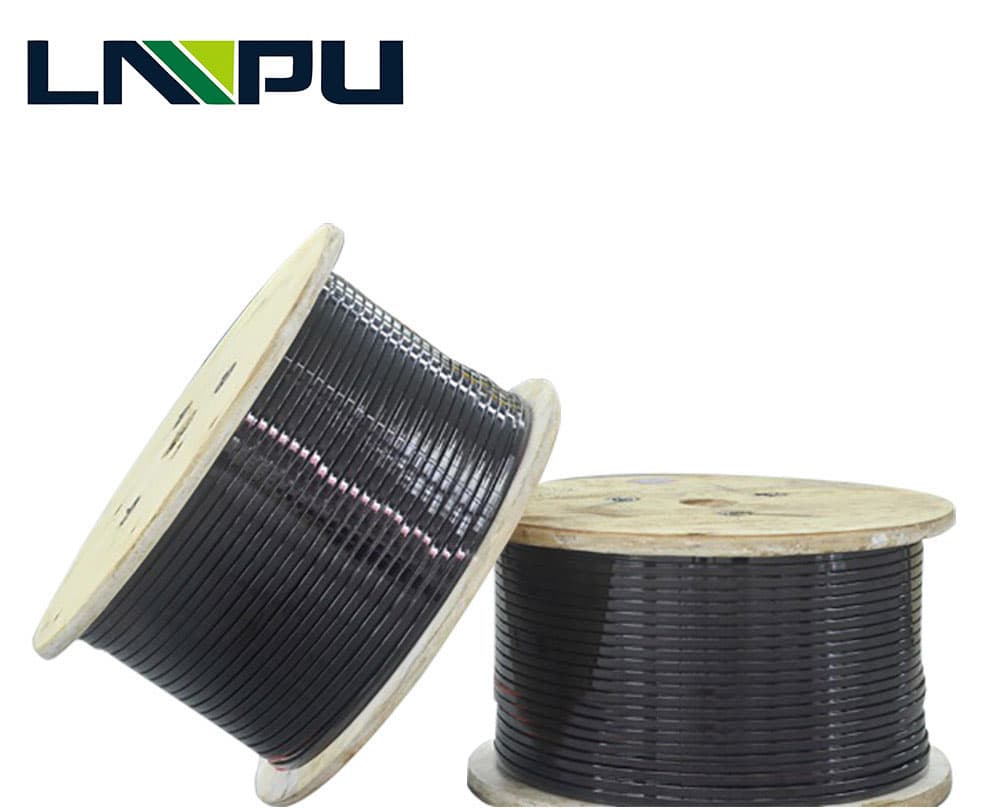

Description Of Enameled Aluminum Wire

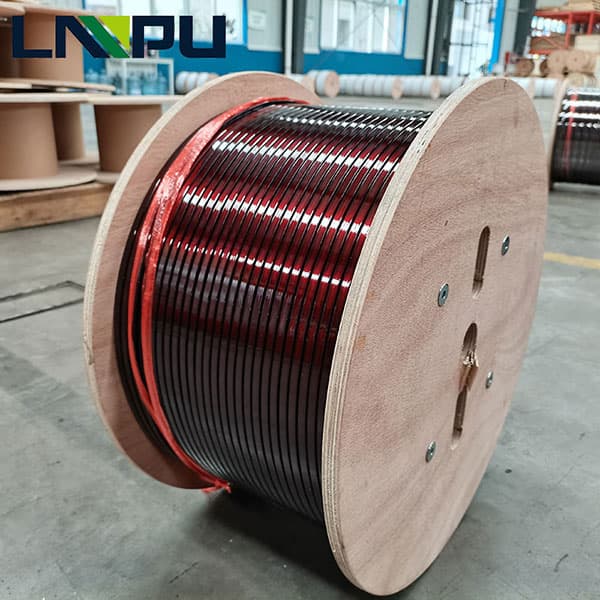

Enameled Aluminum Wire is used for Transformers, Inductors, Motors, Speakers, Hard disk head actuators, Potentiometers, Electromagnets, etc.

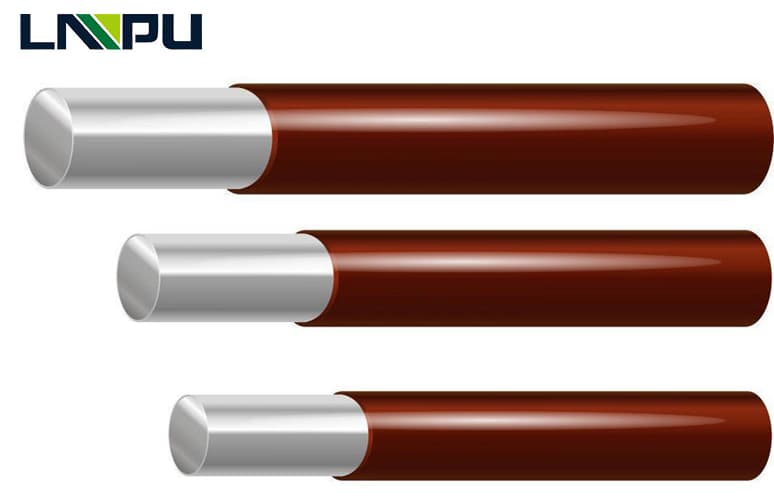

type: flat type and round type

Standard: IEC, NEMA, JIS, GB

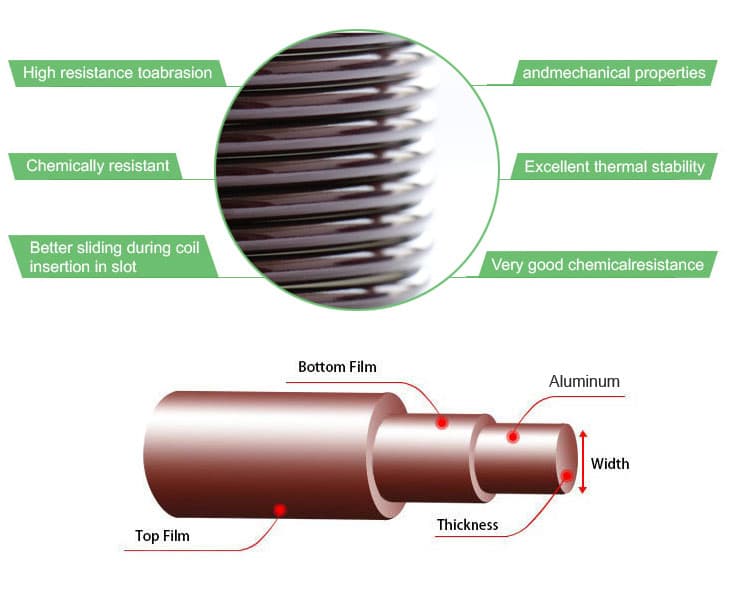

Enameled aluminum wire is one of the main types of winding wire, which is composed of a conductor and an insulating layer. The bare wire is softened by annealing, then painted and baked many times. However, it is not easy to produce products that not only meet the requirements of the standards but also meet the requirements of customers. It is affected by the quality of raw materials, process parameters, production equipment, environment, and other factors. Therefore, the quality characteristics of enameled aluminum wire and enameled copper wire are different. The same, but all have four major properties: mechanical properties, chemical properties, electrical properties, and thermal properties.

Features edit

Enameled aluminum wire has excellent high-temperature resistance, mechanical properties, electrical properties and chemical properties, and excellent

Enameled aluminum wire

Freezing resistance, suitable for long-term refrigeration equipment and chemically corroded electrical equipment, dry-type transformers, oil-immersed transformers, epoxy cast transformers, iron separators, electromagnets, and other electromechanical equipment that work at 200°C for a long time. Enameled aluminum wire is not only used in equipment but also the main raw material commonly used by aluminum artists. Enameled aluminum wire initially.

When used in handicrafts, it was unexpectedly used by the aluminum art master Yang Liehao. Its special color and physicality determine the nobility and elegance of handicrafts.