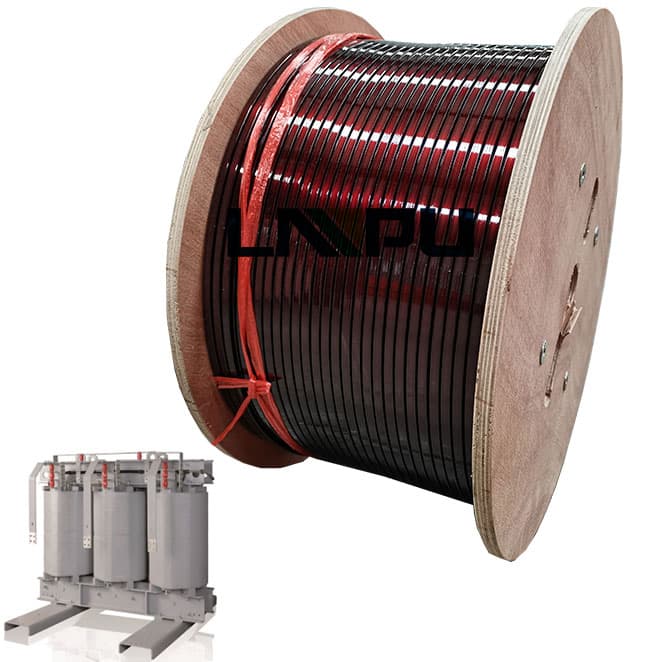

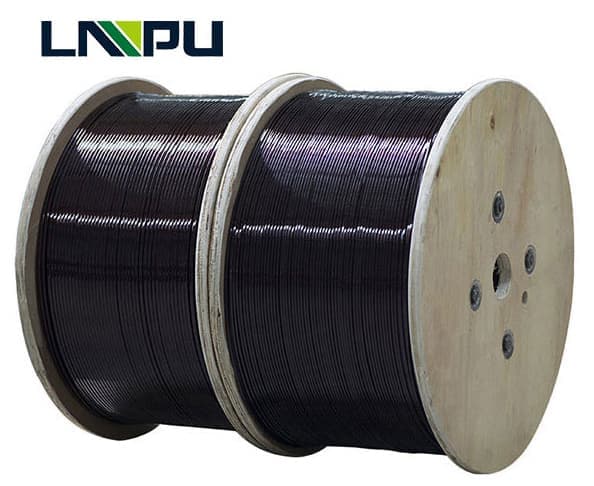

Copper lacquer wire transportation and preservation

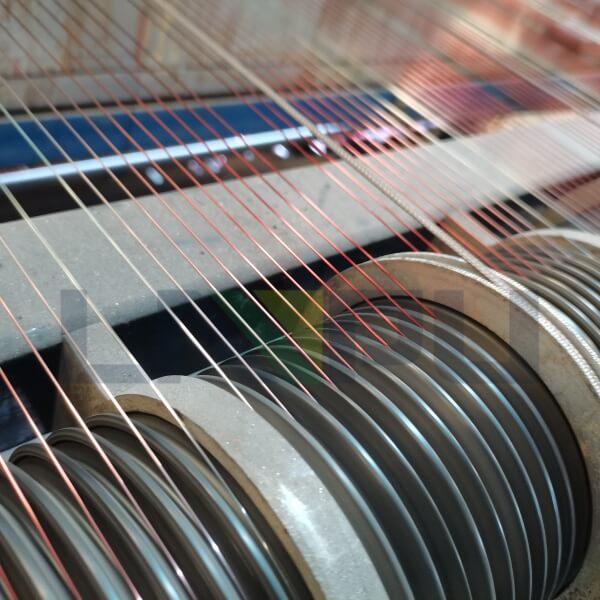

Speaking of the copper enameled wire, I believe everyone should know. Today, we introduce you to a wire, ie the copper paint package. Let us simply look at the transportation and preservation of copper-clad aluminum wires, because if many wires are transported incorrect, it is very likely to be used, so let us simply understand the transportation and preservation of the copper paint wire, so you can be here.

There is a better understanding.

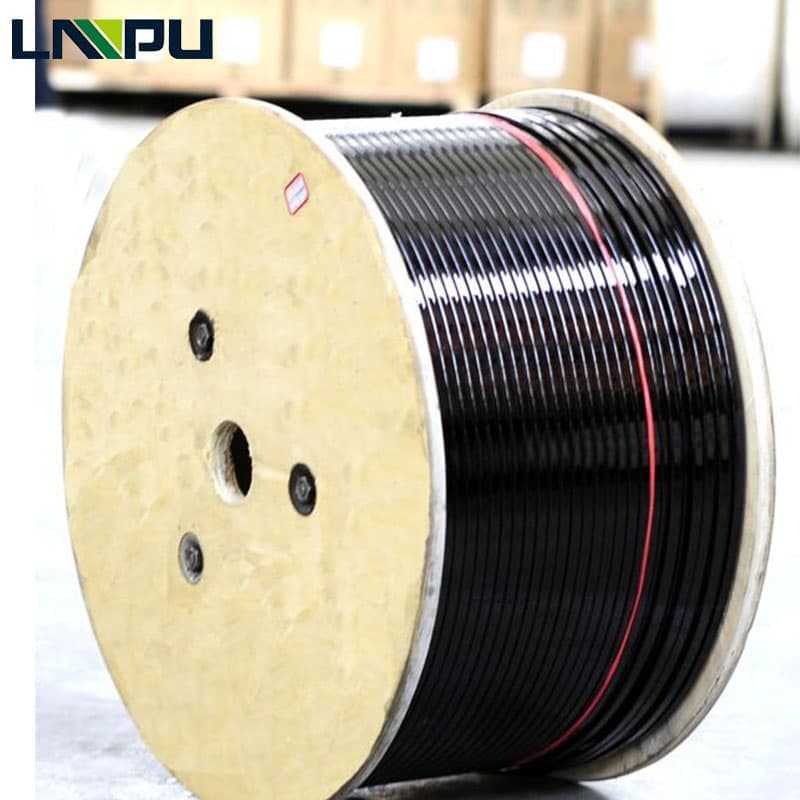

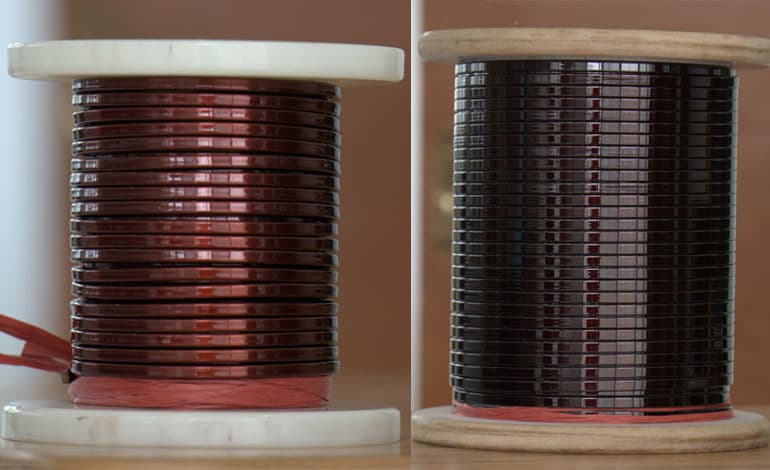

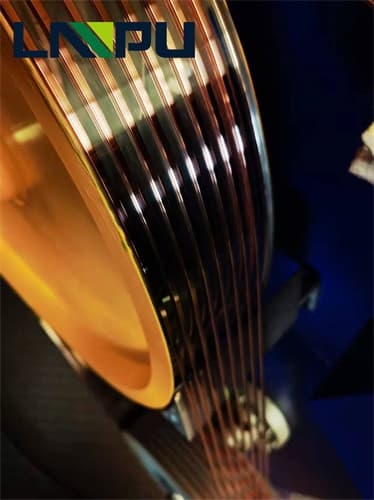

1. During transportation and loading and unloading, the copper-clad aluminum wire and the wire plate should not be injured. It is strictly forbidden to push the copper-clad aluminum wire tray directly from the car. The wire drive should not be transported and stored. 2. Before transporting or rolling coils, it is necessary to ensure that the copper enameled coil is stable and closely wound. When scrolling, you need to follow the direction of arrow or wire in the scroll. 3, the copper paint wiring and its annex arrived at the site, the following requirements should be tested in time:

(1) The product technical paper is complete.

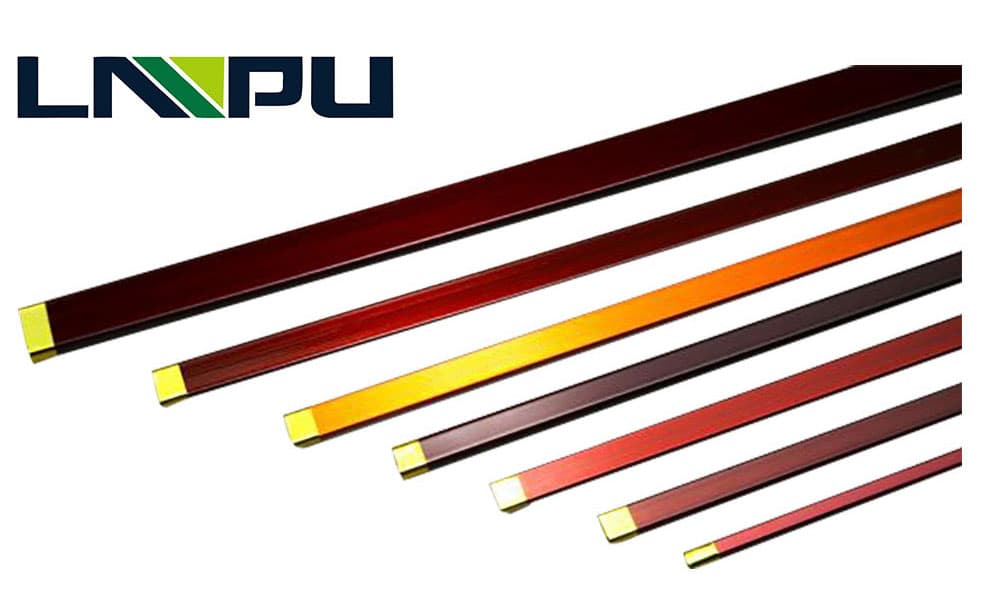

(2) The model, specifications, and length of the production wire should meet the order requirements, the accessories should be complete; the appearance should not be damaged.

(3), the pipewire seal should be careful. When any questions are checked on the appearance, it should be given a moisture judgment or test. 4. If the copper paint wiring and its related materials are not installed immediately, it should be stored in a centralized and classified manner, and the type, voltage, specifications, and length should be indicated.