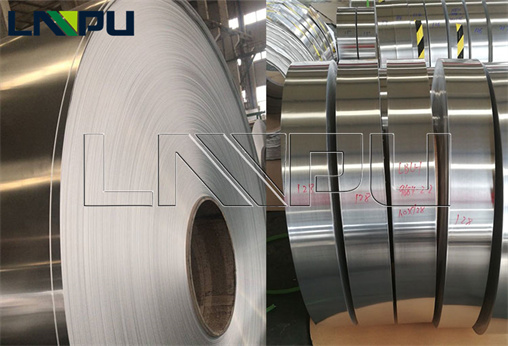

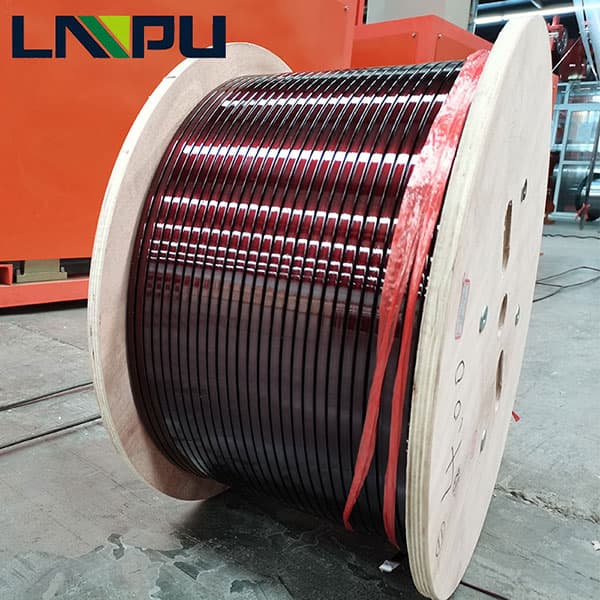

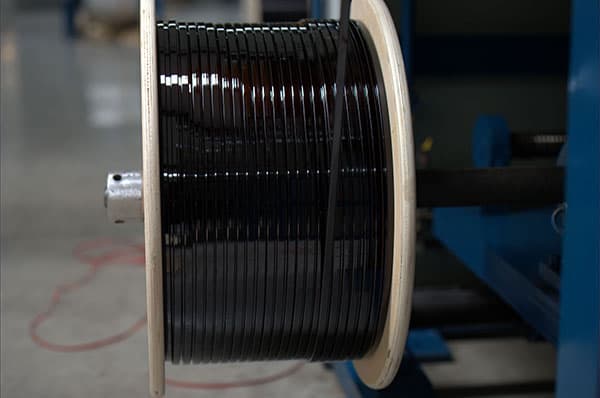

Conductive aluminum film coil 1000 aluminum foil roll strip

Grade: 1000 Series

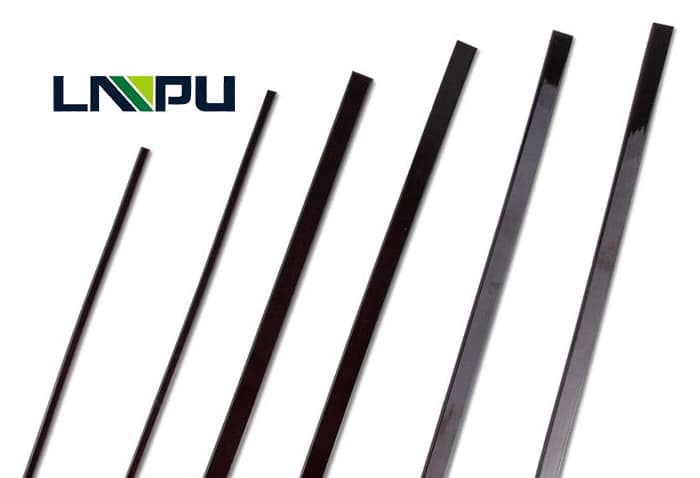

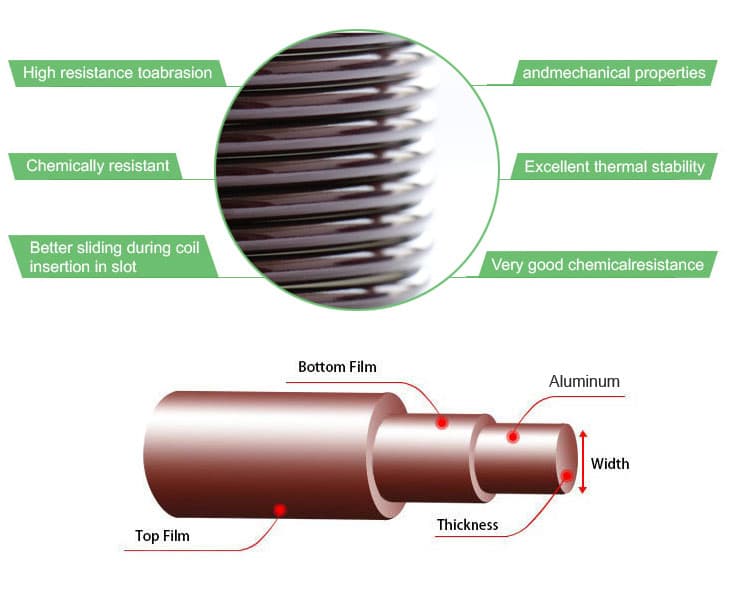

Thickness: 0.2mm–3.0mm

Width: 20mm — 1500mm

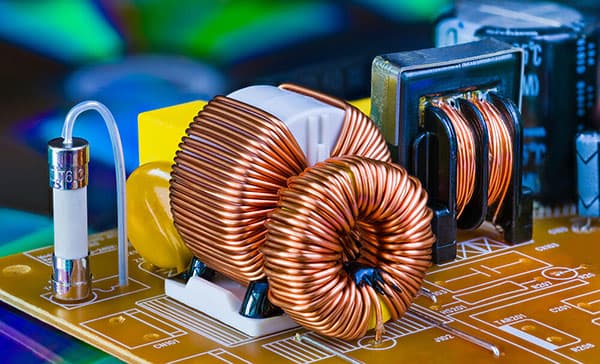

Usage: Dry-type transformers, Distribution transformers

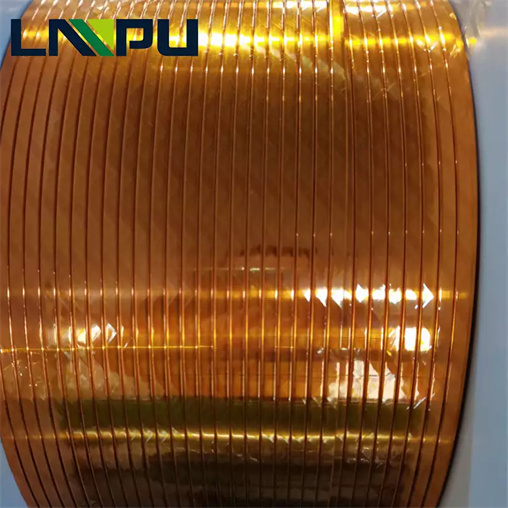

Materials Grade: 1060-O, 1050, 1050A, 1070, 1070A, 1350

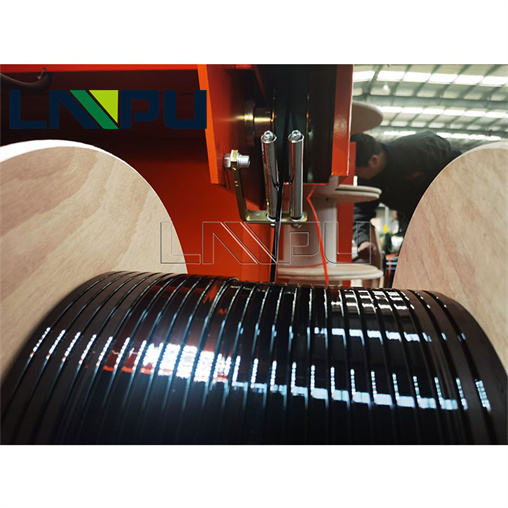

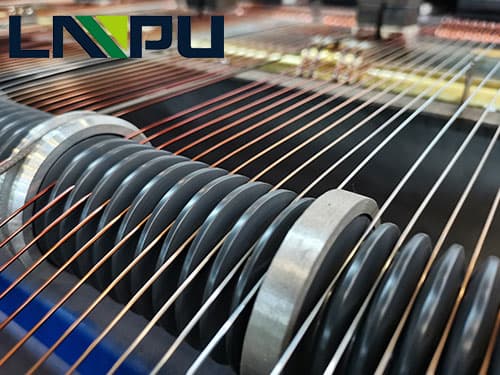

LP Aluminum foils are soft with high conductivity, flat surface, smooth edge and no burr. They are the key raw materials for making Transformer winding. Using qualified Aluminum strip, transformer will have the advantages on compact in size, light weight, nice insulation properties, anti-flame, pollution free, low partial discharge, moisture resistant, stable operation, quiet and low maintenance cost etc.

Transformer aluminum foil or strip generally use Grade 1060 aluminum strip. Its aluminum content are more or less than 99.6%, also known as pure aluminum which is a commonly used series in the aluminum coil family. The advantages of this aluminum coils is the most commonly used series, its production process is relatively simple and the technology is relatively mature, and the price compared to other high-grade aluminum alloy has a huge advantage. This coils have good elongation and tensile strength, and can fully be able to meet the conventional processing requirements (stamping, stretching) high formability.

It’s the industrial pure aluminum with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not be strengthened machinability is not good; gas welding, hydrogen atom welding and contact welding, brazing is not easy; Pressure processing and extension, bending.