Comparison of Chinese winding wire materials with international standards

The raw materials for winding wire mainly include copper, aluminum conductor, insulating paint, insulating paper, polyester mesh belt, polyester film, corona-resistant film, etc.

Domestic materials can basically meet the requirements of use. The imported materials selected according to product characteristics include aramid paper, Minschke insulating paper, Weidmann heat-resistant paper, DuPont 410 paper, DuPont corona-resistant film, etc. to meet the needs of customers. Different high temperature resistance, high mechanical strength, corona resistance and other requirements.

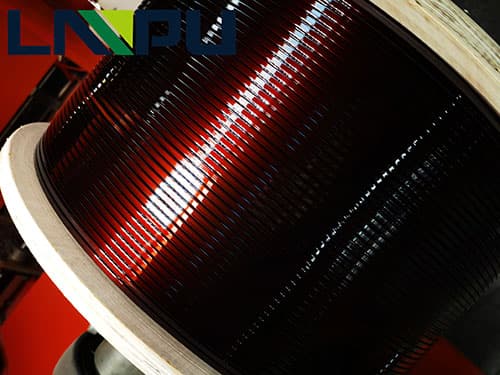

(1) Conductor

For a long time, the winding wire conductors are mainly copper and aluminum. In terms of copper conductors, the quality of China’s copper billet products can meet the actual needs. However, only 8mm continuous casting and rolling rods are produced in China, and there are no copper rods of 10mm and above. As a result, the large-section copper wire can only be produced by the continuous extrusion process using the upper lead copper rod, which has low efficiency and large loss.

(2) Enameled wire paint

As one of the main raw materials of winding wire, enameled wire enamel is a unique insulating material for enameled wire and an essential core material. The demand for enameled wire paint also indirectly reflects the demand for winding wire to a large extent, and most varieties of enameled wire paint are almost exclusively produced for enameled wire.

(3) Insulating paper

For special insulating paper, due to the relatively small industry, the domestic supply chain is relatively weak.

(4) Mica tape

Most of the foreign countries use calcined mica tape as the wrapping wire material, while the domestic mica tape used for wrapping wire is mainly non-calcined mica. Compared with calcined mica, it has more impurities and poor bending performance.

(5) Polyimide film

The output of domestic polyimide film is not low, but it is mainly uniaxially oriented polyimide film produced by casting process. Compared with foreign biaxially oriented film, it has excellent thickness uniformity, mechanical properties and electrical properties. Many differences. Special films with corona resistance function are also produced in China, but the comprehensive performance is still far from DuPont’s similar products.

(6) Dipping paint for glass wire covered wire

Compared with the same type of glass fiber covered wire produced in China, there is a big gap in technical indicators such as flexibility and breakdown voltage, which is mainly caused by dipping paint.