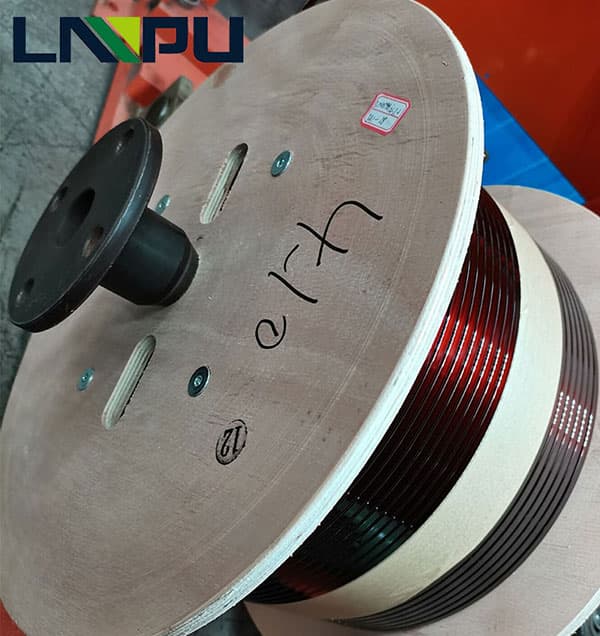

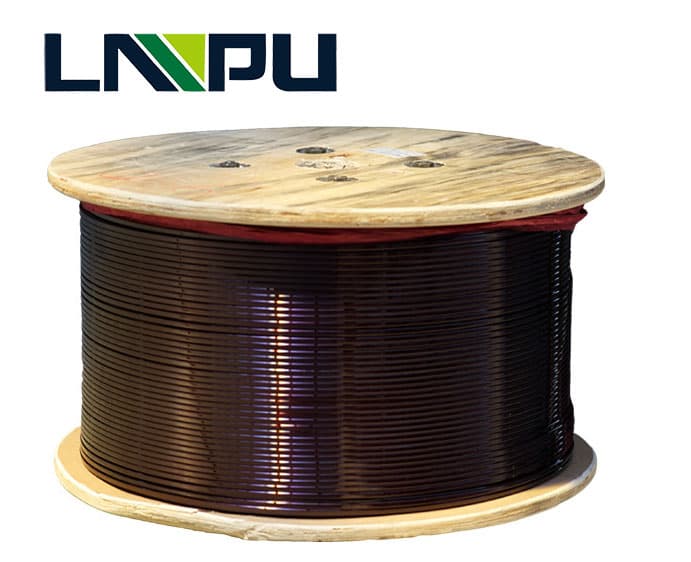

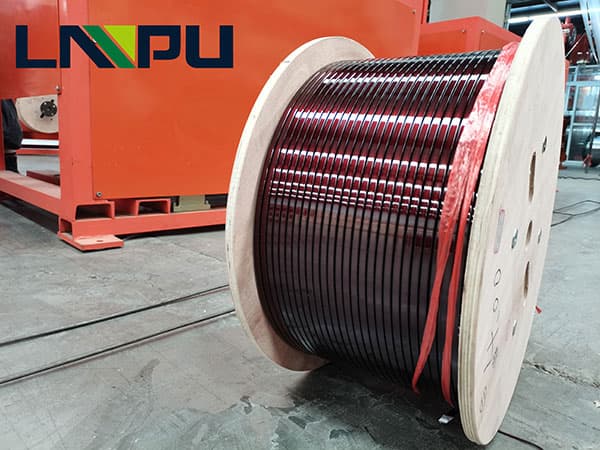

Class 180/200/220 self-bonding solderable over-coated enameled Aluminium wire

Specifications of Ultral Fine rectangular Enameled Aluminum Wire:

1 Type:

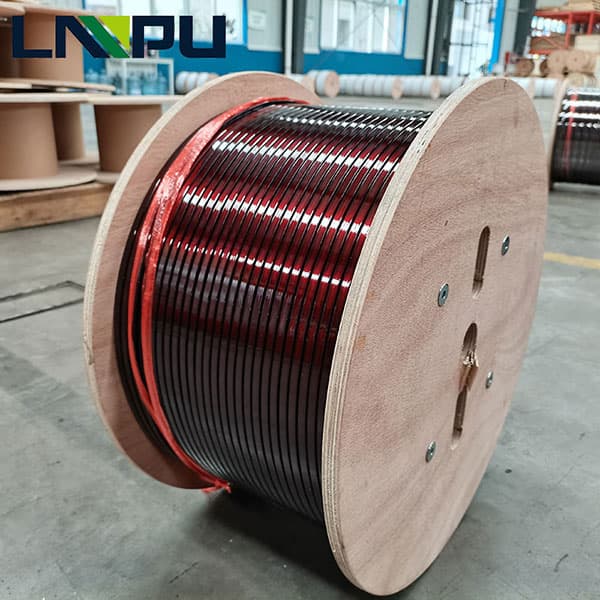

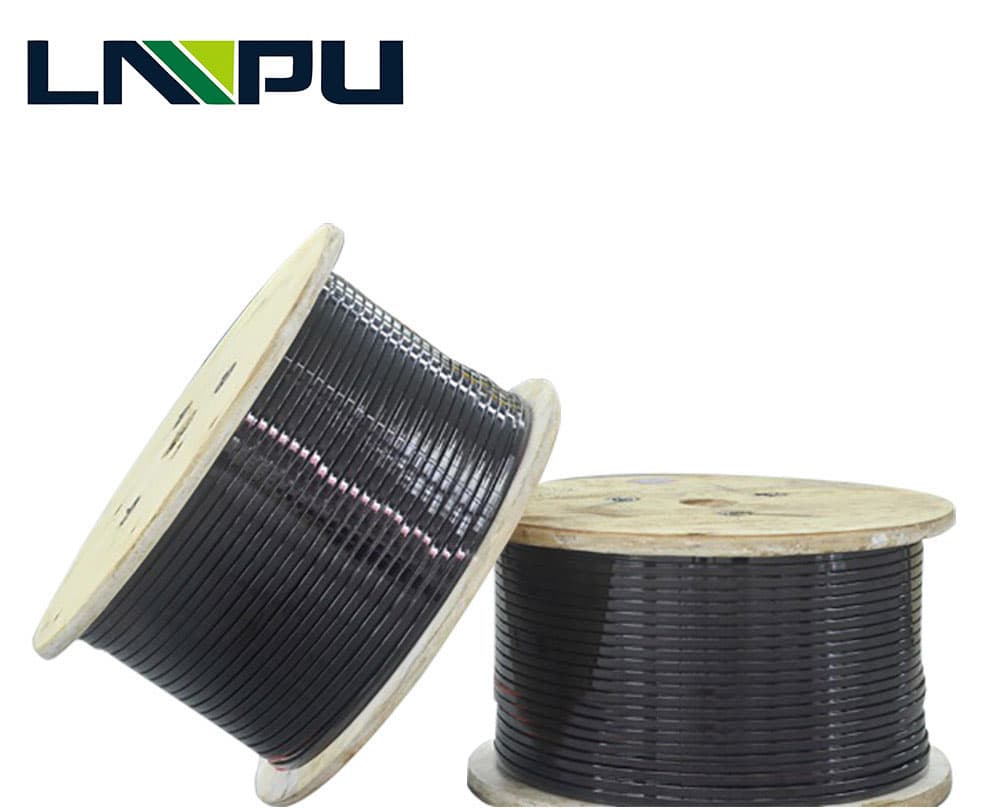

Enameled aluminum round and flat wire

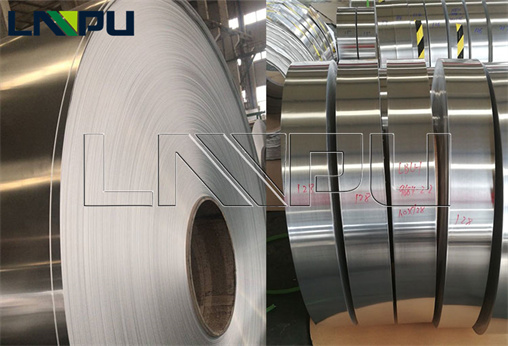

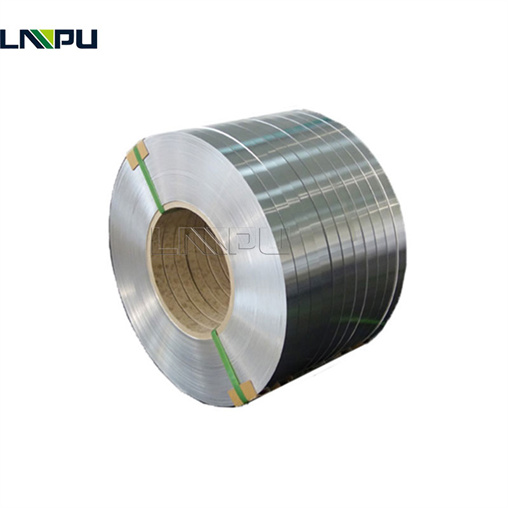

2 Base material:aluminum

3 Space factor:

1)Appro*78% Array winding

2)Appro*91% Array winding

3)Appro*96% Edgewise winding

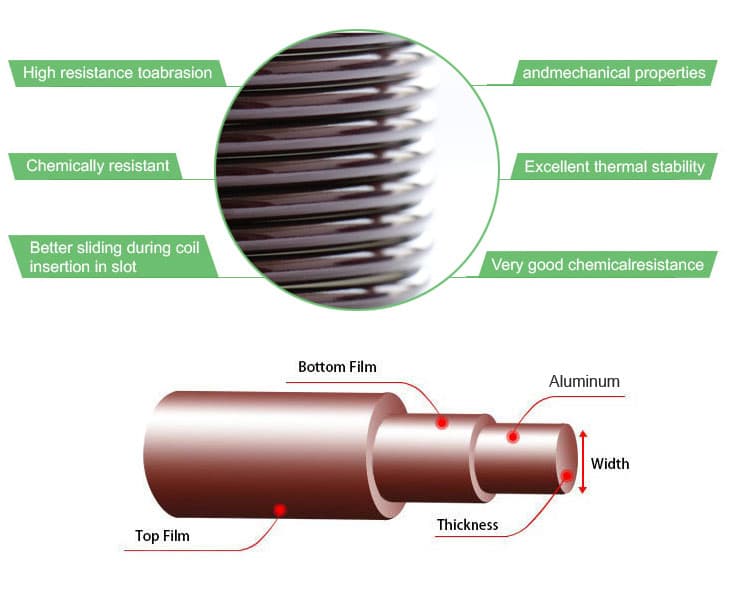

4 Structure:Insulating film bonding film , Aluminium wire

5 Size:0.050-0.800mm

Features of Ultral Fine rectangular Enameled Aluminum Wire:

High temperature resistance

Chemical corrosion resistance

Transformer oil resistance

Low temperature resistance

Radiation resistance

High breakdown voltage

Good mechanical properties

Other features: Self-bonding,solderable

Material :

High quality aluminum;

Good quality of insulation varnish;

Standard :

Applicable standard or part of the reference standard

IEC60317-0-2

IEC60317-29

Application :

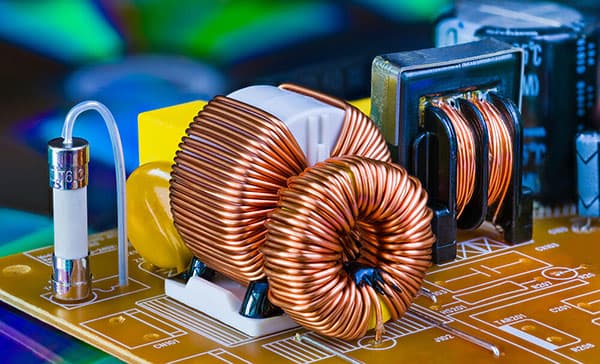

Electronic transformer;

Mico motor;

Computer cable;

Voice coil and other application purposes;

1) Voice coils

2) Moving coils

3) Hollow coils for motors

Can be winded neatly to increase the slot fullness and reduce the space, excellent formability, more surface area, good heat dissipation.