China’s enameled wire industry technology development status

Enameled wire is used for camcorder, electronic clock, micro relay, automobile, electronic instrument, washing machine, TV element, etc. Development direction in the diameter, use the specification range of ¦Õ0.06 ~ 0.08 mm and all thickened insulation

[1) Diameterization

Due to the miniaturization of the electrical product, such as camcorder, electronic clock, micro relay, automobile, electronic instrument, washing machine, TV element, etc. Development direction in the diameter. For example, color electricity high-pressure packets, such as integrated wire, output the flushing transformer, using the segmental groove, use the specification range of ¦Õ0.06 ~ 0.08 mm and all thickened insulation, and is now designed to change to a flat wind method. After the interlayer insulation is wound, the wire diameter is changed to ¦Õ0.03 to 0.04 mm, and the lacquer layer can be.

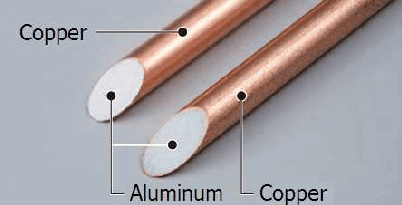

(2) Lightweight

According to the design requirements of the electrical product, the lightweight method employed in some cases in which it is required is to materialize light weight rather than the diameter, such as some requirements. Not high micro motor, speaker voice coil, artificial pacemaker, microwave transformer, etc. Light, low price, there is also a shortcomings of difficulty in processing, poor welding, tensile strength. Only a microwave oven transformer, according to my country’s production of 10 million units per year, it is considerable.

(3) Self-adhesive

Special properties of self-adhesive enameled wires are manifested in windless boneless coils or impregnated. Mainly used in color TV deflection, speaker voice coils, buzzers, micro motors, electronic transformers, etc. According to the different combinations of the bottom paint, the selection of materials also have different heat resistance, which can meet different use occasions. This variety is considerably used in electroacoustic and color TV deflection.

Due to the diameter of the lacquer wire, the market demand in the micro-wire is increasing, considering that the micro-wire is small in the winding process, the system is difficult to break, in order to improve safety tension Taking into account other features, the alloy copper that is mixed with other ingredients is considered to increase the safety tension greatly improved. At the same time, the decwire in conductivity is almost, such as Japan’s Dong Te. HTM wire safety tension is 125% of ordinary copper wire, the conductivity is 93%, and the wire specification is ¦Õ0.015 ~ 0.10mm.

Consistency of winding parameters

For occasions, inductance, inductance, distribution capacitors such as resistance, inductance, distribution capacitance, etc., the lacquer wire wire diameter conductor tolerance and outer diameter tolerance cannot be satisfied with the standard It must be strictly controlled to reduce the tolerance band, which puts higher requirements for the production process, production equipment, and the general production process and domestic lacquer wire equipment can not meet this production requirements.

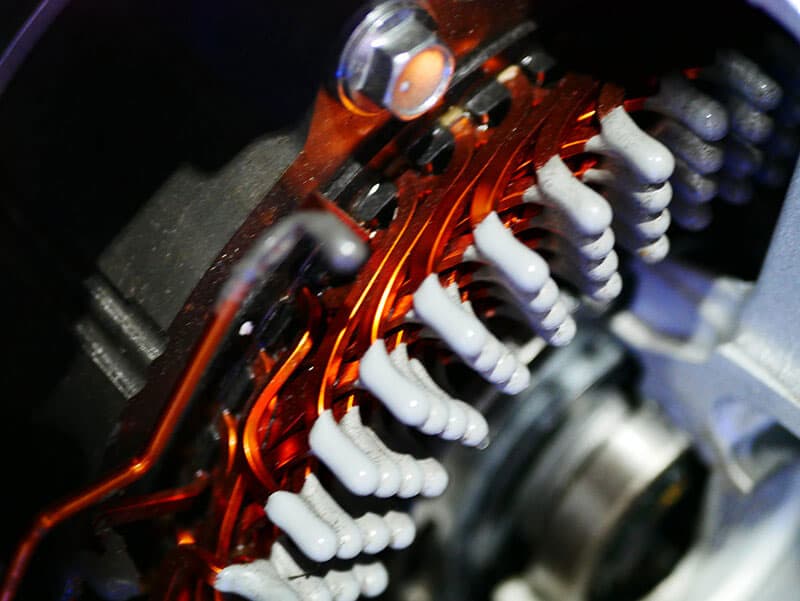

¢Ê High-voltage high voltage characteristics and high Q value characteristics

Electrical products are in addition to the development of miniaturization, meet a variety of needs, and adapt to a variety of environments and should pay more attention. For example, in the enamel wire, improve the use frequency, the high peak voltage of the winding coil and the wire, and the assessment of the winding coil is test high frequency turntable pressure and the like.

Heat fuse

Special outside of thermal blowing wireThe insulating layer has thermal blow protection characteristics, so it is widely used in the power transformer, which is used to wind a primary coil. When the coil is overflow or temperature rise exceeds a certain particular value, the outer insulating layer of the enamel wire is rapidly melted, resulting in short circuit protection of the power supply to avoid damage to the machine.

Heat resistance, cold media, direct welding

The mainstream of domestic products is:

Heat resistant wire: modified polyester paint brlass F-class; polyester Imaly-enameled wire: H-class; cold-resistant medium wire: polyester imine / polyamide imide C-stage straight welding wire: polyurethane paint package wire B, F-stage

The above product has been basically mature, and is gradually starting Occupy the dominant position of the home appliance product, but in the insulting paint, the above-mentioned several products have a paint or less there is some problems to be solved, such as: heat resistant to the moisture resistance, polyurethane paint wire Cracking, self-lubricity, solder no residue, softness, etc. There is a fairly gap between similar products, and it has to be improved.

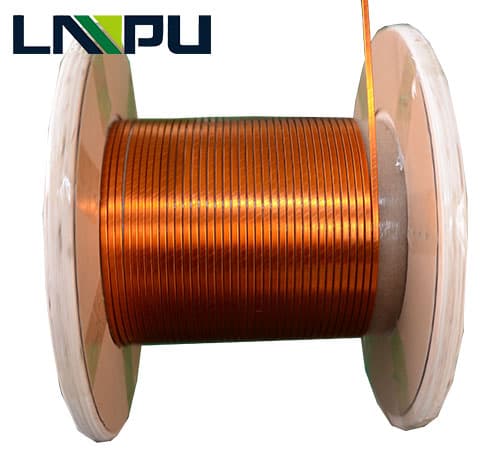

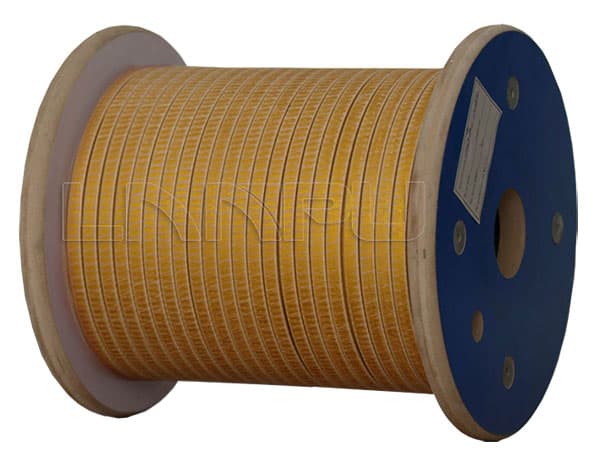

¢Í ¢Í ¢Í,, in the coil winding process, there is a problem with a volumetric share of a lacquered wire in the skeleton in the process of winding. The maximum share of the round wire is 91%, the electrical product The development of miniaturization is bound to require components to be miniaturized, and increasing volume share is one of the problems necessary to consider the coil design. Common methods have a square wire, a rectangular flat wire, an increased volume share, which can reach 96%, which is widely used on a high-power speaker voice coil. In addition, in terms of LITZ wire winding power supply transformer, due to the thickness of the Litz wire, the volume share is small.

Non-magnetic and high electrical conductivity

We produce copper materials used in the enameled wires or less magnetic elements and other impurities such as iron, nickel, cobalt, and other impurities, while others need to exclude these interference Or obtain high conductivity, therefore puts higher requirements for copper, there is no good processing performance and has good electrical performance, which has applied single crystal copper to some high-fidelity digital transmission and some foreign countries. Precision meter.