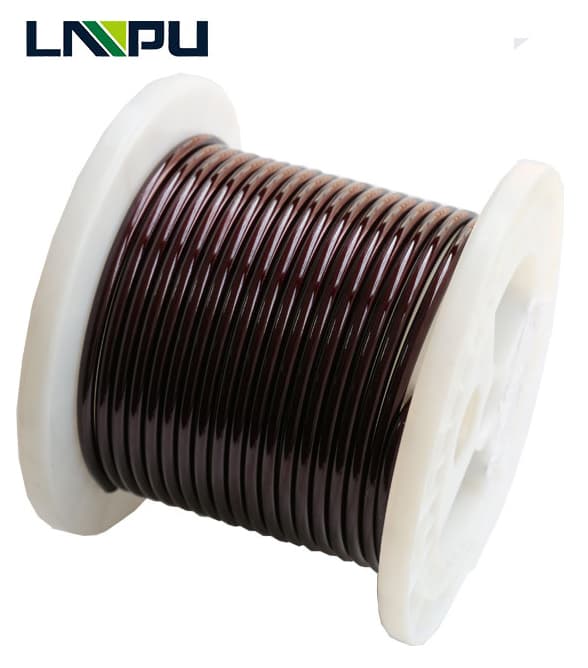

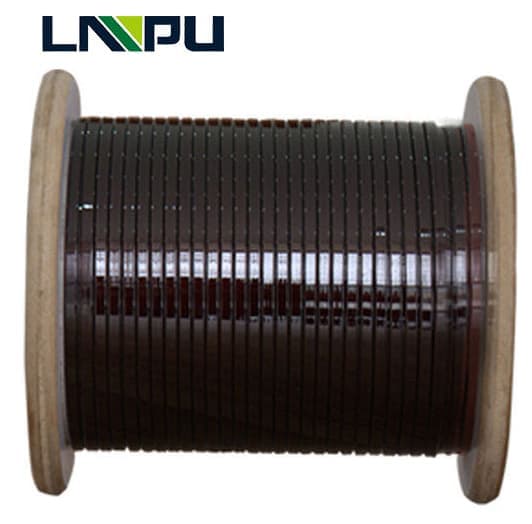

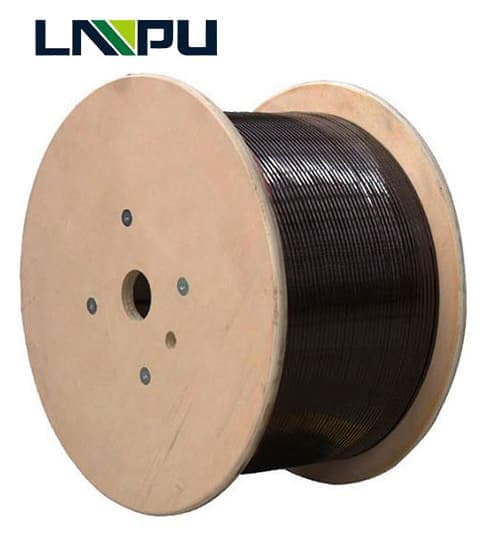

China Manufacturers Enamelled Aluminum Electric Submersible Winding Wires

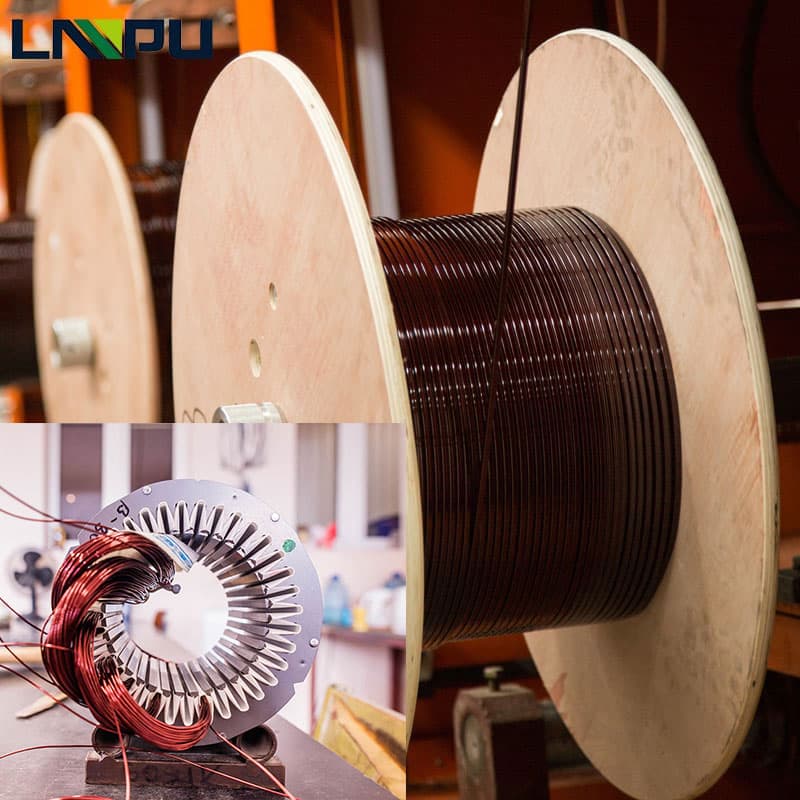

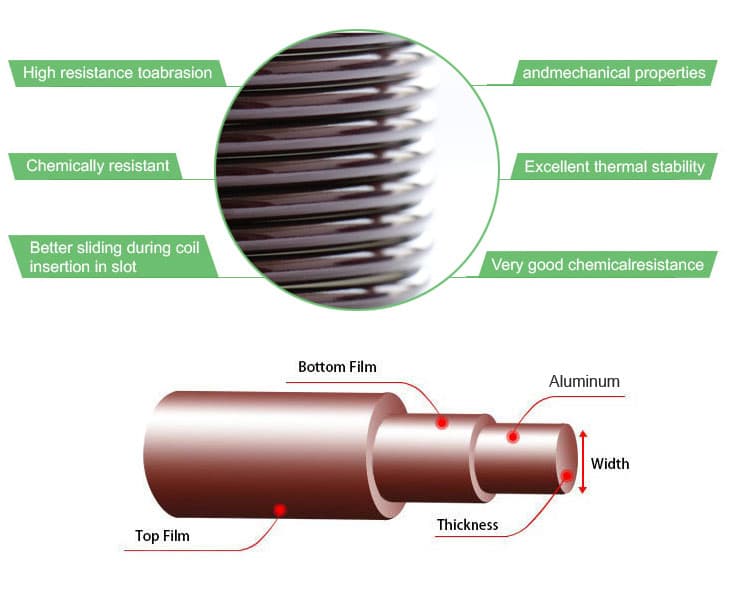

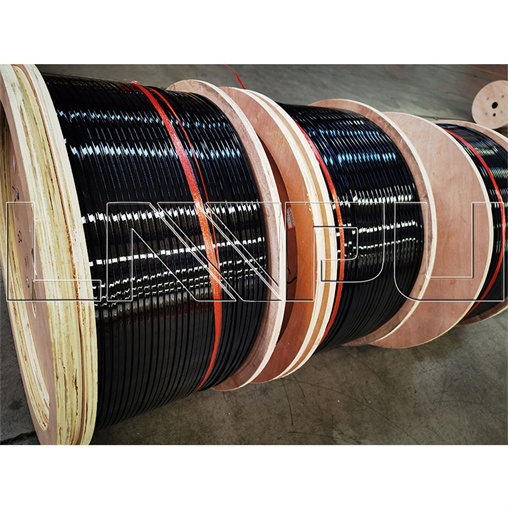

China Manufacturers Enamelled Aluminum Electric Submersible Winding Wires is used in the manufacture of submersible motor windings. Submersible motors are mostly used for oil extraction in oil mines and work at high temperatures. In order to maintain the internal and external pressure balance, the interior including the windings are immersed in high-pressure (for example, 10 MPa) water-containing oil. In order to avoid joints, the windings are mostly made of a single magnet wire repeatedly wound in the slot of the motor, so the insulation layer is required to have good wear resistance. Usually polyimide film is used to wrap the covered wire.

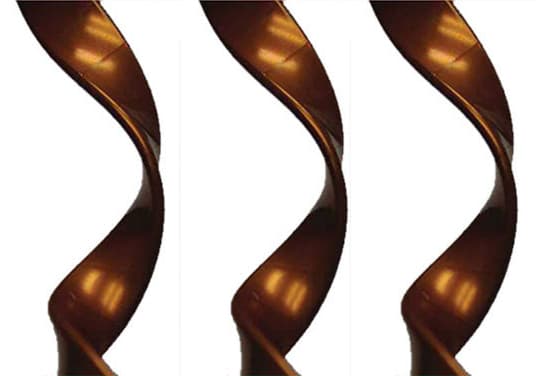

Polyimide film has excellent heat resistance, dielectric properties, oil and water resistance, for example, long-term oil-water resistance test at 155 ¡æ, its electrical properties and appearance have no obvious changes. Since the film itself is infusible and insoluble, it cannot form a continuous sealed insulation. Usually a layer of fluorine-46 plastic is coated on the upper surface or the upper and lower sides as an adhesive, which is called HF film.

The submersible wire is wrapped with HF film in multiple layers, and the number of layers depends on the voltage and mechanical properties. For example, when the rated voltage of the motor is 1000 volts, a three-layer film half-overlap is used for wrapping, and then high-temperature sintering is performed to melt the fluorine-46 into a continuous sealed integral insulation.