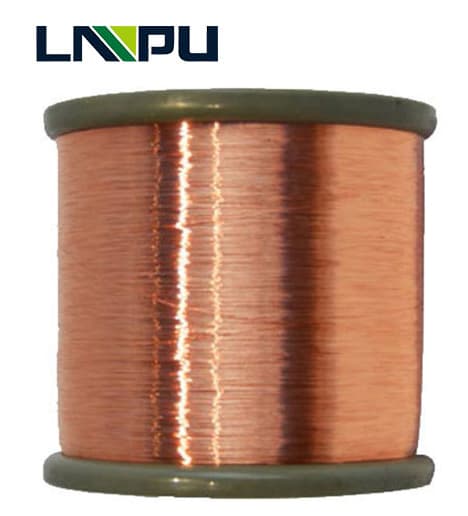

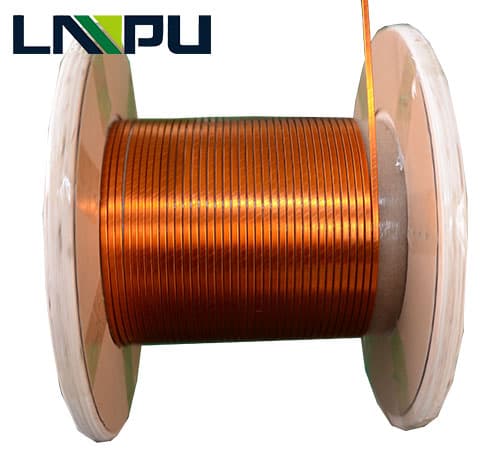

china manufacturer insulated winding flat copper aluminum magnet wire

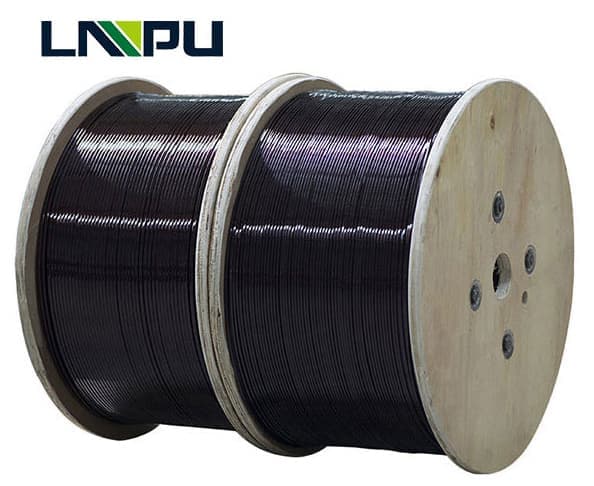

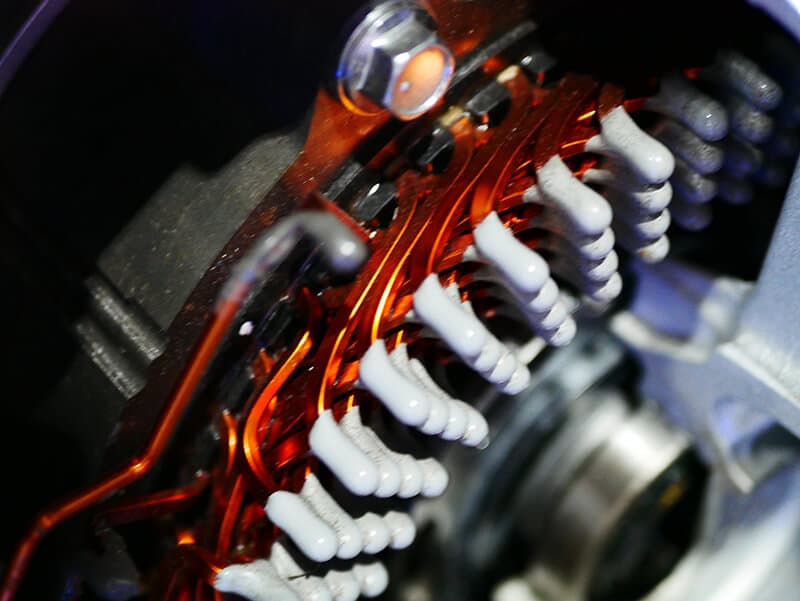

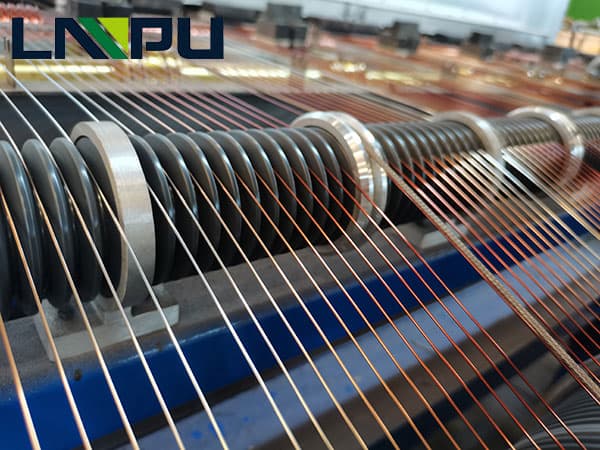

Flat enameled wire is a type of enameled wire. It is a winding wire made of oxygen-free copper rods or electrical aluminum rods that are drawn, extruded or rolled by a certain specification die, and then coated with insulating paint for many times. The thickness is from 0.025mm To 2mm, the width is generally less than 5mm, and its aspect ratio ranges from 2:1 to 50:1. Flat enameled wire has a wide range of uses, especially in the windings of various electrical equipment such as telecommunication equipment, transformers, motors and generators.

Feature:

Compared with general enameled wire, flat enameled wire has better softness and flexibility, and has excellent performance in current carrying capacity, transmission speed, heat dissipation performance and occupied space volume. It is especially suitable for electrical and electronic equipment. Jumper wires between circuits. In general, flat enameled wire has the following characteristics:

(1) The occupied volume is smaller. Flat enameled wire occupies less space than enameled round wire coil, which can save space by 9-12%, and the production volume of smaller and lighter electronic and electrical products will be less affected by the volume of the coil, which will obviously save more Material;

(2) The coil slot full rate is higher. Under the same winding space conditions, the slot full rate of the flat enameled wire can reach more than 95%, which solves the problem that the coil is difficult to improve for a long time, so that the resistance is reduced, the capacitance is larger, and the application of large capacitance and high load can be better met. The requirements;

(3) The cross-sectional area is larger. Flat enameled wire has a larger cross-sectional area than enameled round wire, and its heat dissipation area is also increased accordingly, and the heat dissipation effect is significantly improved. At the same time, it can greatly improve the “skin effect” (when the alternating current passes through the conductor, the current will be concentrated in the The surface of the conductor flows) to reduce the loss of high-frequency motors.

Because of the great advantage of copper in electrical conductivity, flat enameled wires are generally made of copper today, that is, flat enameled copper wires. For different performance requirements, the flat enameled copper wire can be adjusted accordingly according to the characteristics of the required performance. For example, for components with particularly high requirements for flattening and light weight, flat paint with ultra-narrow, ultra-thin and large width-to-thickness ratio is required. Copper-clad wire; For components with particularly high requirements for low power consumption and high performance, high-precision flat enameled copper wires need to be produced; and for components with particularly high impact resistance, high-toughness flat enameled copper is required Wire; For parts that require a particularly high service life, durable flat enameled copper wires are required.