Can Enameled Aluminum Wire And Enameled Copper Wire Be Connected?

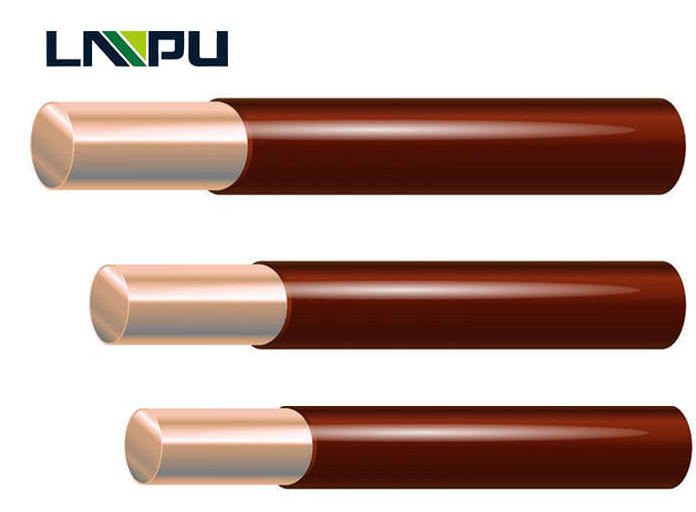

Enameled Aluminum Wire connects Enameled Copper Wire with the short service life according to the test. The contact part of the enameled copper wire and the enameled aluminum wire will accelerate the oxidation of the aluminum wire.

The electric potential of enameled copper wire and enameled aluminum wire is different. Due to the reaction of the galvanic battery, the contact part of the enameled copper wire and the enameled aluminum wire will accelerate the oxidation of the aluminum wire. After long-term use, the connection of the enameled aluminum wire connector of the enameled copper wire will deteriorate. time. If you want to connect them together, you must use enameled copper wire and enameled aluminum wire to wrap or wrap the pipe.

This is a chemical problem. The chemical properties of metals are relatively reactive and inert. For example, gold never rusts, which means gold has no chemical activity, iron just rusts, and iron is more active than gold. Putting the metals together will accelerate the oxidation of the active metals. Compared with enameled copper wire, enameled aluminum wire is more active. The connection of the two cables will accelerate the oxidation (ie rust) of aluminum and affect the application.

When copper and aluminum conductors are directly connected, the contact surfaces of these two metals can easily form an electrolyte under the action of moisture in the air, carbon dioxide, and other impurities, and then use aluminum as the negative electrode to form a primary battery. The use of copper as the positive electrode causes galvanic corrosion of aluminum, which then causes the contact resistance of the junction between copper and aluminum to increase.

In addition, due to the large difference between the modulus of elasticity and thermal expansion coefficient of enameled copper wire and enameled aluminum wire, after multiple cooling and heating cycles (power-on and power-off) during operation, there will be Create a larger gap. Influence contact. It also increases the touch resistance. Increasing the touch resistance will cause the temperature to rise during operation. Corrosion and oxidation at high temperatures will intensify, leading to a vicious circle, which will further deteriorate the quality of the connection, resulting in excessively high contact temperatures, and even accidents such as smoke and burns. Or it would be wiser to seek help from the enameled wire factory.