Best Selling 155 Class Enamelled Copper/Aluminum Winding Wire

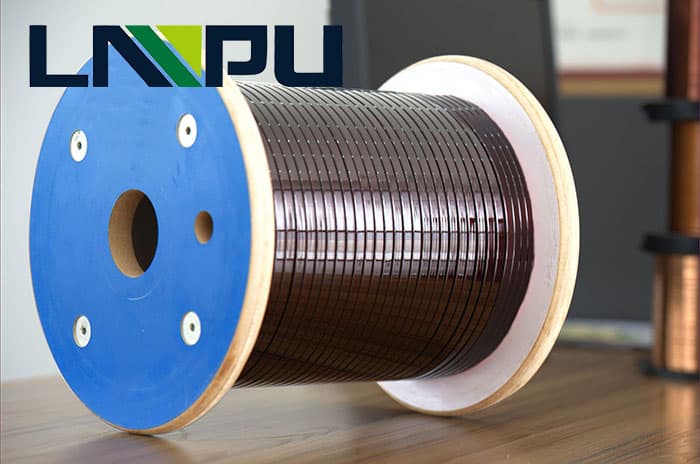

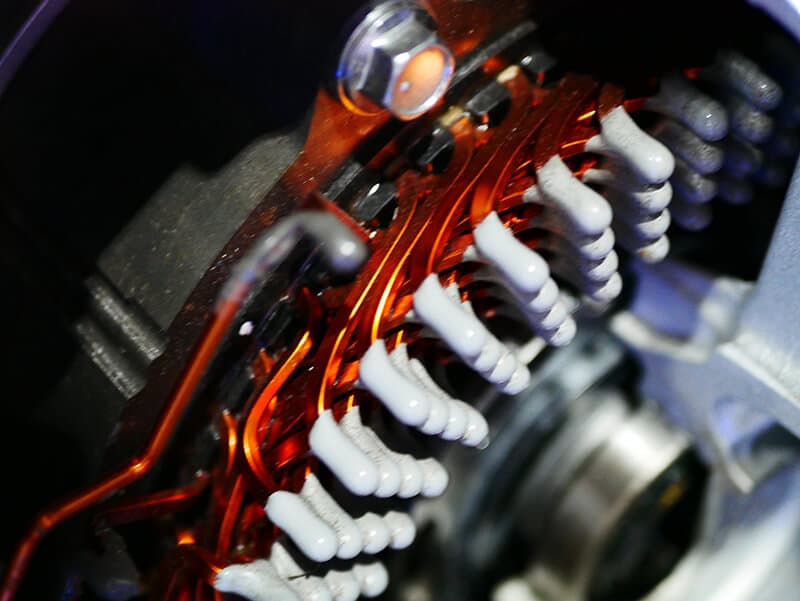

Best Selling 155 Class Enamelled Copper/Aluminum Winding Wire includes copper wire and aluminum wire used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers. Thermal Class:Class 155, popular used for low voltage dry type transformers.

The most suitable materials for magnet wire applications are unalloyed pure metals, particularly copper. When factors such as chemical, physical, and mechanical property requirements are considered, copper is considered the first choice conductor for magnet wire.

Self-supporting coils are wound with wire coated with at least two layers, the outermost being a thermoplastic that bonds the turns together when heated.

Other types of insulation such as polytetrafluoroethylene (Teflon) can be found. Older insulation materials included cotton, paper, or silk, but these are only useful for low-temperature applications (up to 105¡ãC).

For ease of manufacturing, some low-temperature-grade magnet wire has insulation that can be removed by the heat of This means that electrical connections at the ends can be made without stripping off the insulation first.

Classification

Like other wire, magnet wire is classified by diameter (SWG or millimeters) or area (square millimeters), temperature class, and insulation class.

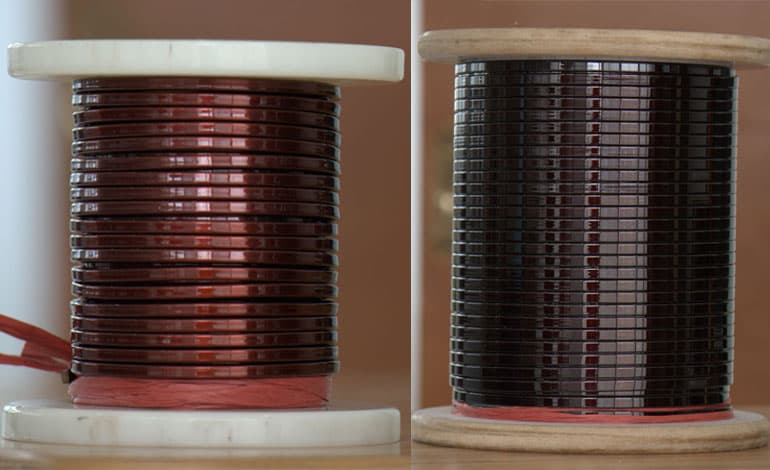

Cross-sectional view of magnet wire taken using a scanning electron microscope

Breakdown voltage depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher breakdown voltages.