Copper Magnet Wire Manufacturing Process

Copper Magnet Wire Manufacturing Process includes important three steps – enameling, winding and Inorganic insulated wires. Mainly introduce the method to ensure the quality of copper enameled wire.

We can classify it according to the basic composition of copper magnet wire, conductive core, and electrical insulation. Generally, according to the insulating material and manufacturing method used in the electrically insulating layer, it is divided into enameled wire, winding wire, and inorganic insulated wire.

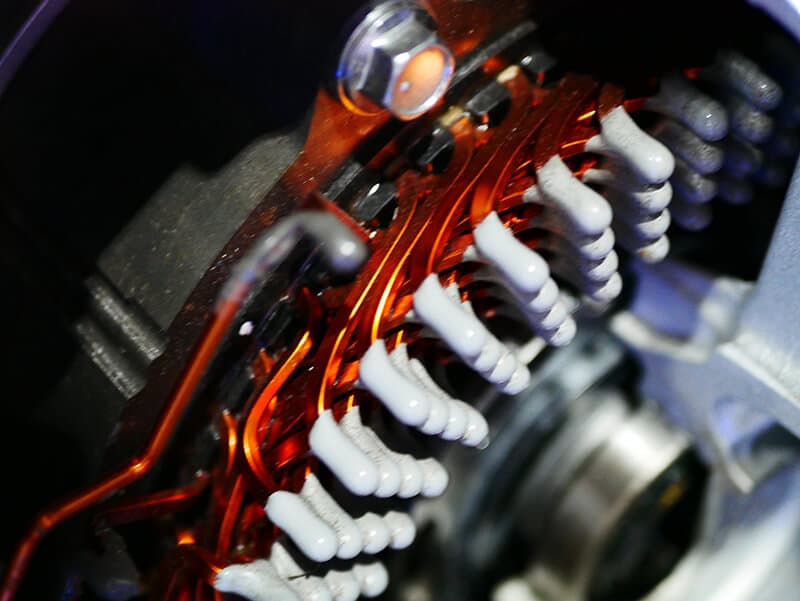

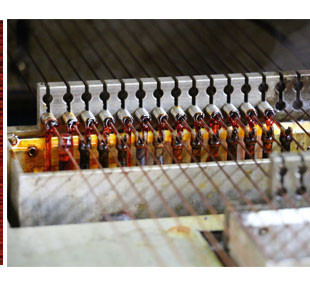

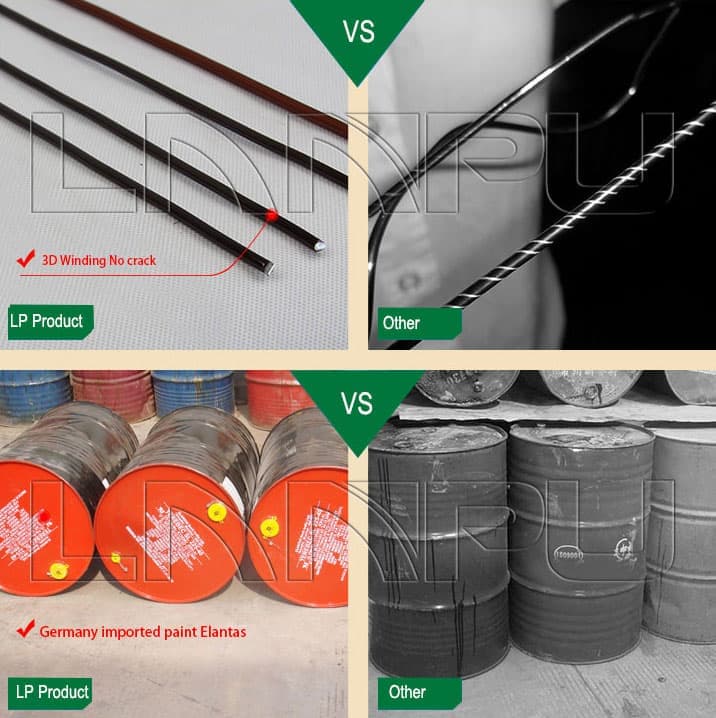

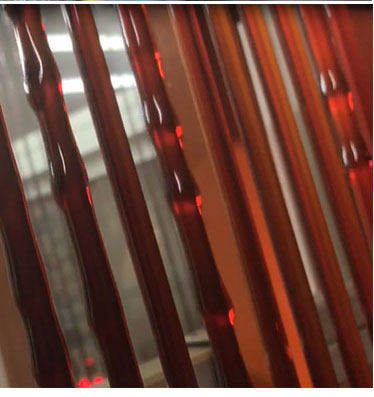

Enameled wire: Coat the corresponding varnish solution on the outside of the conductor, and then make it through solvent volatilization and coating film solidification and cooling. Enameled wire can be divided into polyester enameled wire, polyester imide enameled wire, polyamide-imide enameled wire, polyimide enameled wire, polyamide-imide enameled wire, corona-resistant enameled wire, oil paint, shrinkage Aldehyde paint, polyurethane enameled wire, etc. It is also classified according to the particularity of its use, such as self-adhesive enameled wire, refrigerant-resistant enameled wire, etc.

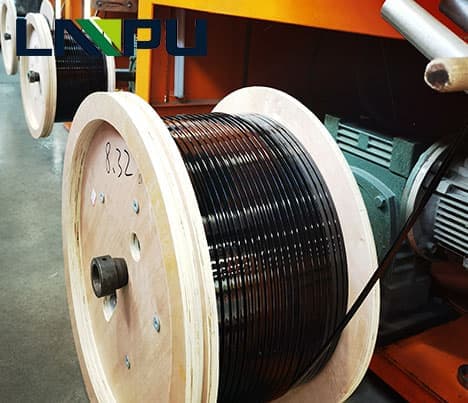

Winding: an important variety of winding. In the early days, cotton yarn and silk were called yarn-covered wire and silk-covered wire, which were used in motors and appliances. Due to the large thickness of the insulating layer and low heat resistance, most of them have been replaced by enameled wires. Currently only used as high-frequency winding wire. In large and medium-sized winding wires, when the heat resistance level is higher and the mechanical strength is higher, glass fiber coated wires are also used, and appropriate bonding paint is used in the manufacturing. Paper-covered wire still occupies a considerable position in the wrapped wire and is mainly used for oil-immersed transformers. The oil-paper insulator formed at this time has excellent dielectric properties, low price, and long life. In recent years, film wrapping lines have developed rapidly, mainly polyester film and polyimide film wrapping lines.

Inorganic insulated wires: When the heat resistance level exceeds the limit of organic materials, inorganic insulating varnishes are usually used. The existing inorganic insulated wires can be further divided into glass film wires and oxide film wires.