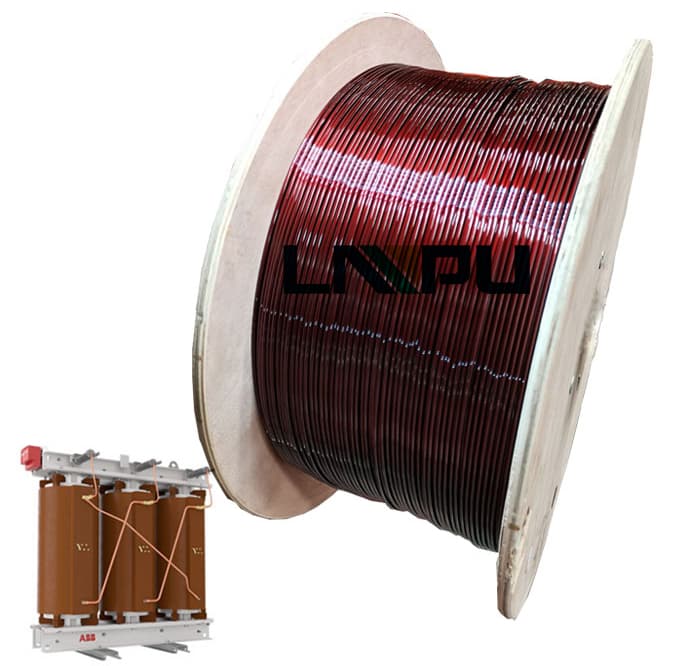

Aromatic polyimide tape-covered aluminum magnet wire

For Aromatic polyimide tape-covered aluminum magnet wire, after the aluminum magnet wire is taped with a tape that is 1.5 mm thick with 1.0 mm of this thickness being polyimide film and the remaining 0.5 mm being fluoroplastic, it is heated and heat-sealed.

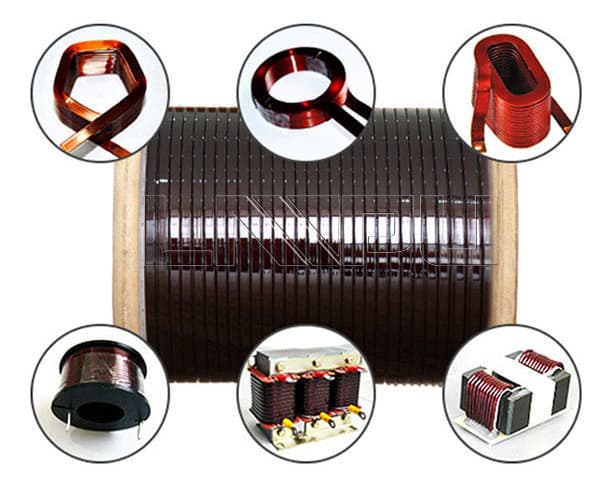

Aromatic polyimide tape-covered aluminum magnet wire has a higher space factor than that of glass-fiber covered aluminum magnet wire and fully satisfy class-H heat resistance requirements. When Aromatic polyimide tape-covered aluminum magnet wire is used as substitute for these glass-fiber covered aluminum magnet wire, electrical equipment can be expected to be reduced in size and weight. Aromatic polyimide tape-covered aluminum magnet wire has electrical characteristics and coating flexibility far superior to those of glass-fiber covered aluminum magnet wire. Aromatic polyimide tape-covered aluminum magnet wire is primarily used for electric motors in vehicles, large direct current machines, and drytransformers. However, the aluminum magnet wire is more costly than other winding aluminum magnet wires. It is recommended, therefore, to use them when, there are problems in terms of space factor in particular. The aluminum magnet wire is inferior to glass-fiber covered aluminum magnet wire in corona resistance. When using the aluminum magnet wire in high-pressure equipment, special consideration must be given to insulation design.

Conductor materials:

1.Polyimide film Covered Aluminum magnet wires strips should follow the standard of GB5584.3-85, at 20¡æ its conductivity resistance should be not more than 0.02801¡æmm2/m.

2.Flat conductor size and R angle should be in line with the national standard GB/T7673.1-87;

3. The surface of the round conductor shall be smooth, clean, without any abrasion, burr, oil and metal foam.

4. The connection of circular and flat conductor plane should be smooth, with sharp protrusions and not allowed.