Application of wholesale enameled wire

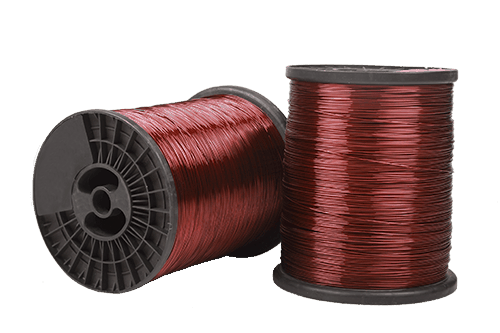

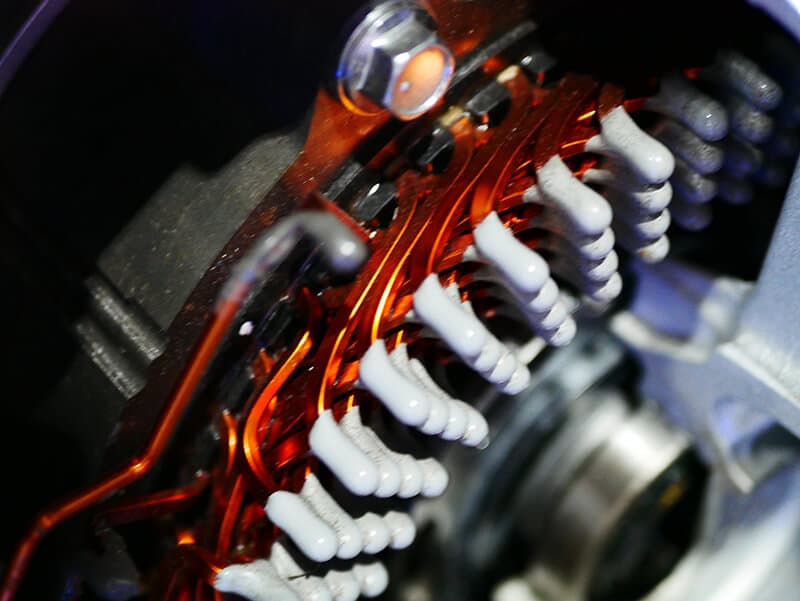

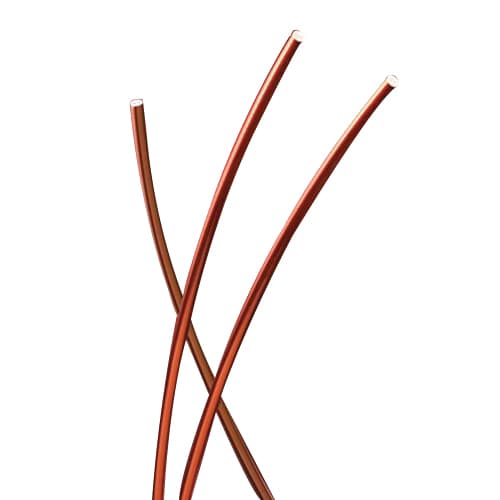

Enameled wire is a main type of magnet winding wire. It is composed of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. However, it is not easy to produce products that not only meet the requirements of the standard, but also meet the requirements of customers. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have Mechanical properties, chemical properties, electrical properties, and thermal properties

1. Acetal enameled wire with two thermal grades of 105 and 120. It has good mechanical strength, adhesion, resistance to transformer oil and refrigerant, but the product has poor moisture resistance, low thermal softening breakdown temperature, and durable benzene-alcohol mixed solvent Weak performance and other defects, only a small amount is used in the windings of oil-immersed transformers and oil-filled motors.

2. For polyester and modified polyester enameled wires, the thermal class of ordinary polyester enameled wires is 130, and the thermal class of enameled wires after modification is 155. The product has high mechanical strength, good elasticity, adhesion, electrical properties and solvent resistance. The weakness is poor thermal shock resistance and low moisture resistance. It is currently the largest product in China, accounting for about two-thirds, and is widely used in various motors, electrical appliances, meters, telecommunications equipment and home appliances.

3. Polyurethane enameled wire; thermal grades are 130, 155, 180, 200. The biggest feature is that it has direct solderability, good high frequency resistance, easy coloring, and good moisture resistance. It is widely used in electronic appliances, precision instruments, telecommunications, and meters. The weakness of this product is that the mechanical strength is slightly poor, and the heat resistance is not high. , And the flexibility and adhesion of the production of large-size wires are poor, so the specifications of the product are mostly small and medium-sized wires.

4. Polyesterimide/polyamide composite enameled wire, thermal class 180. This product has good thermal shock resistance, high softening and breakdown temperature, excellent mechanical strength, good solvent and refrigerant resistance, and its weakness is that it is easy to resist under closed conditions. Hydrolysis is widely used in windings of motors, electrical appliances, meters, power tools, and dry-type power transformers that require high heat resistance.

5. Polyesterimide/polyamideimide composite layer enameled wire is a heat-resistant enameled wire widely used at home and abroad. Its thermal class is 200. This product has high heat resistance, and is also resistant to refrigerants, cold, and radiation. Features, high mechanical strength, stable electrical performance, good chemical resistance and refrigerant resistance, and strong overload capacity. It is widely used in refrigerator compressors, air-conditioning compressors, electric tools, explosion-proof motors and motors and electrical appliances used under conditions such as high temperature, high cold, radiation resistance, and overload.