Application of 200-class enameled aluminum flat wire

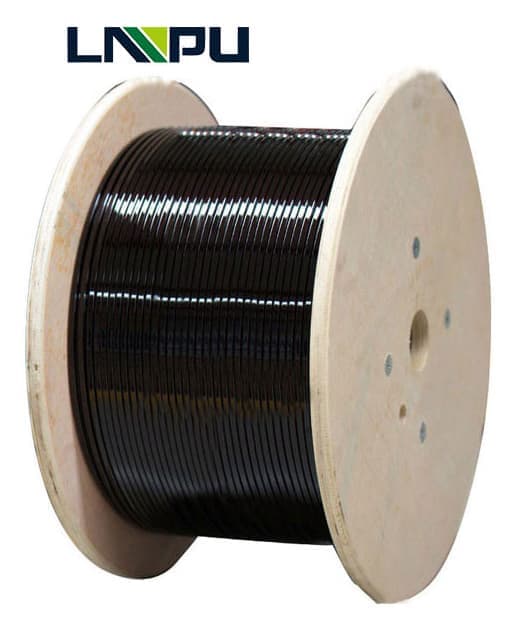

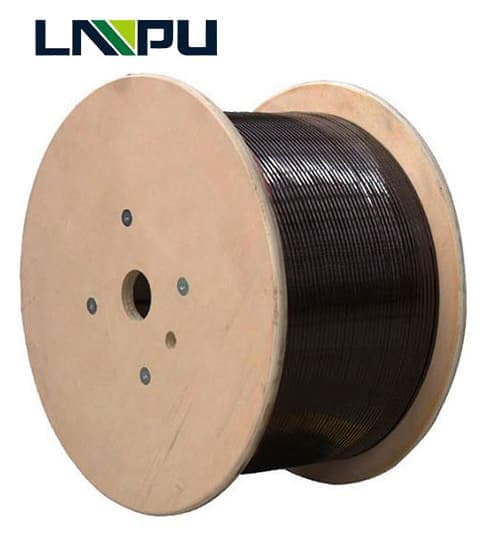

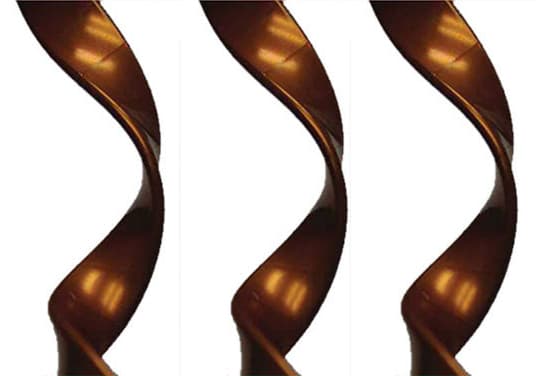

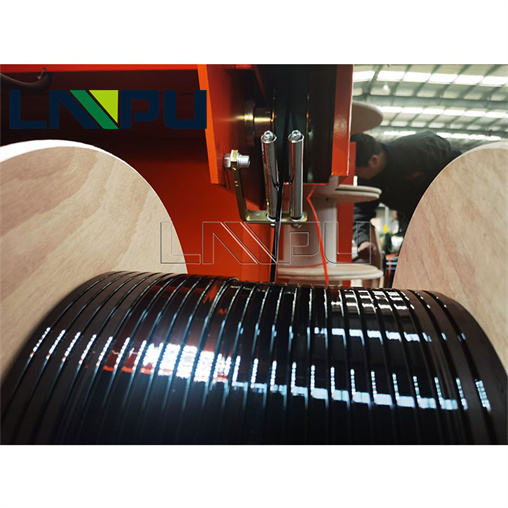

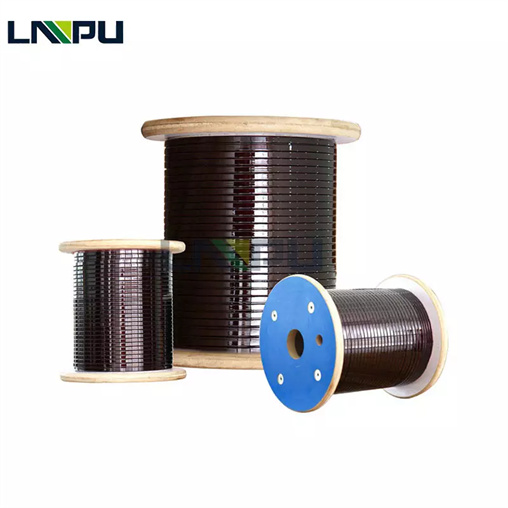

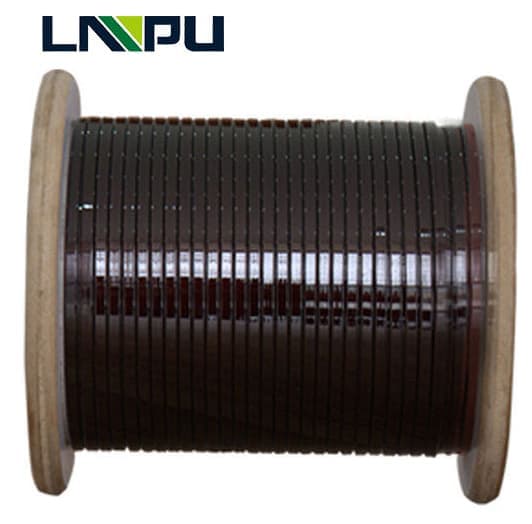

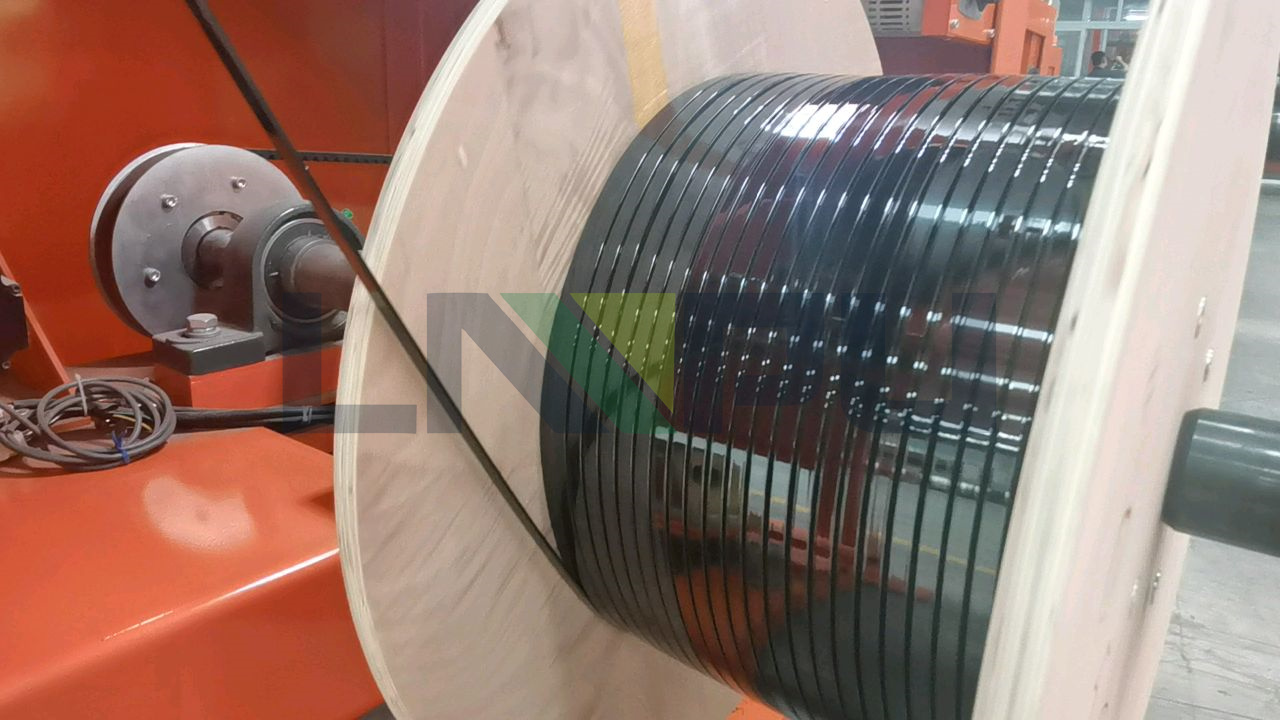

Class 200 enameled aluminum flat wire is a kind of winding wire that is coated with polyester-imide composite polyamide-imide insulating varnish on the surface of electrical aluminum wire as the conductor, and baked at high temperature. It has light weight. Easy to wind and relatively low cost, it is widely used in the windings of motors, UPS power supplies, intermittent power supplies and other products.

With the influence of high copper prices in recent years, 200-class enameled aluminum flat wire, as a new product, replaces enameled copper wire used in windings of motors, UPS power supplies, intermittent power supplies and other products. Its function is similar to enameled copper wire, its specific gravity is smaller than that of copper, its price is much lower than that of copper, its cost is greatly reduced, and it has excellent insulation and heat resistance, which has attracted wide attention from the industry. Enameled aluminum flat wire is mainly composed of aluminum conductor and insulating varnish. Due to the characteristics of aluminum and the problem of processing technology, China’s enameled aluminum wire has not been widely developed for many years, especially in the aspect of enameled aluminum flat wire. More lagging behind, the main reason is that there are many shortcomings in the traditional wire-making process.

There is no national standard or industry standard for enameled aluminum flat wire. Therefore, we have formulated our own corporate standard based on the American NEMA (American Electrical Manufacturers Association) standard. The main performance control indicators are conductor size, conductor fillet size, and paint film. Items such as thickness, dimensions, elongation, resilience, flexibility and adhesion, solvent resistance, DC resistance, room temperature (high temperature) breakdown voltage, thermal shock, etc.