Application and Advantages of enameled round aluminum wire

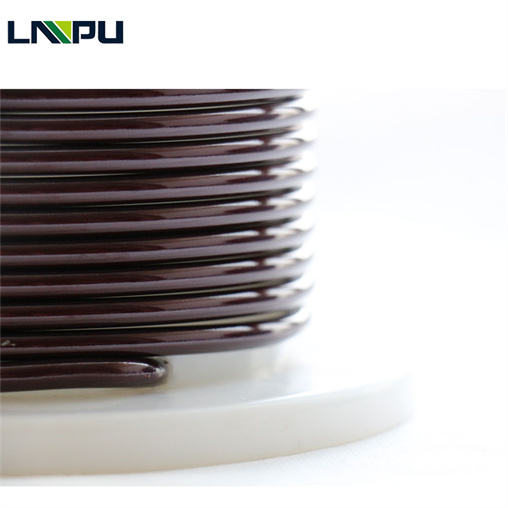

Aluminum is not only cheaper than copper, but also as an excellent conductor, it has better flexibility than copper, its density is only 1/3 of copper, and the same weight of aluminum conducts electricity twice as much as copper; therefore, aluminum Wire requires a larger wire gauge than copper wire to conduct the same current.

Compared with copper, another advantage of enameled round aluminum wire is that the NEMA standard recognizes aluminum wire as a higher thermal enameled wire. For example, replacing copper wires with aluminum wires, using high-temperature polyester TeresterR@ C966, and composite polyamide-imide topcoat, the thermal level can be increased from 200 to .220. The reason is that during the aging experiment of the enameled copper wire, the catalysis of copper ions promotes the aging of the paint film.

Application of enameled round aluminum wire

| Application | insulating varnish requirement | insulating varnish type |

| Microwave oven transformer, reactor | Composite coating above 200 level (PE, PEI/PAI) | Primer: Tongvar 308, Tongvar 355, Terester 966 Finish: Tongmid 595 |

| Motor | B, F grade PE, PU | Tongsold 220£¬Tongsold 240£¬Terestera 966 |

| Ballast | Single coating or composite coating above grade H (PE, PEI/PAI) | Primer: Tongvar 308, Terester 966 Finish: Tongmid 595 |

| Rectifier or other transformer | B, F, H single coating or composite coating (PU; PE; PEI:/PAI) | Terester 966, Tongsold 220, Tongsold 240Tongvar 308 |