Aluminum Wire: the new trend in transformer winding

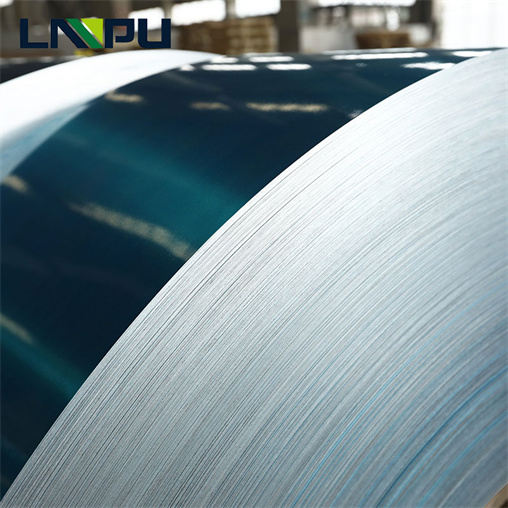

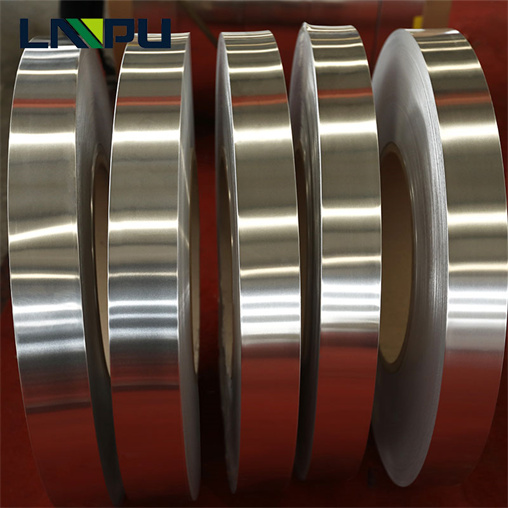

In North America, aluminum is the predominant choice of winding material for low-voltage, dry-type transformers larger than 15 kilovolt-amperes(kVA).

In most other areas of the world, copper is the predominant winding material. The primary reason for choosing aluminum windings is its lower initial cost.

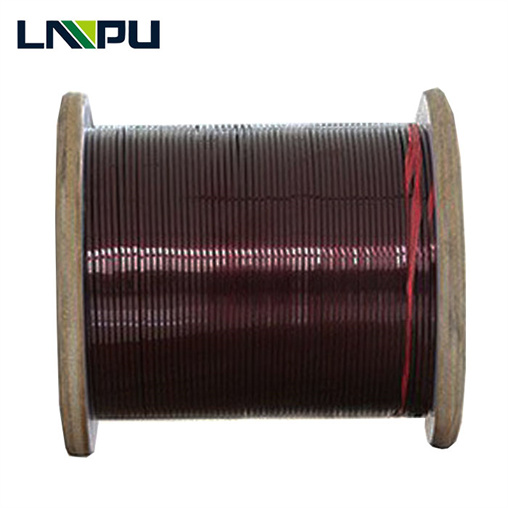

The cost of copper base metal has historically proven to be much more volatile than the cost of aluminum, so that the purchase price of copper conductor generally is the most expensive choice. So the enameled copper wire is not same with the Aluminum wire. Also, because aluminum has greater malleability and is easier to weld, it is the lower-cost manufacturing choice.

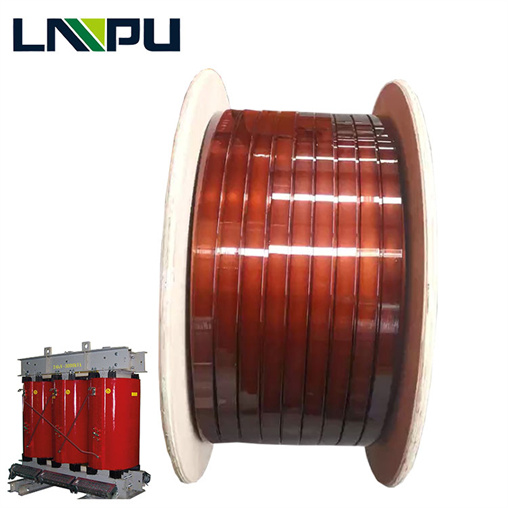

However, reliable aluminum connections require more discipline and expertise on the part of transformer installers than that needed for copper connections.

For aluminum coils to achieve the same current-carrying capacity as copper, the aluminum coil must be approximately 66% larger in its cross-sectional area. Responsible manufacturers design and test the hot-spot characteristics of their designs and utilize cooling surface area, coil geometry, air ducting, and conductor shape to produce acceptable hot-spot gradients regardless of winding material.

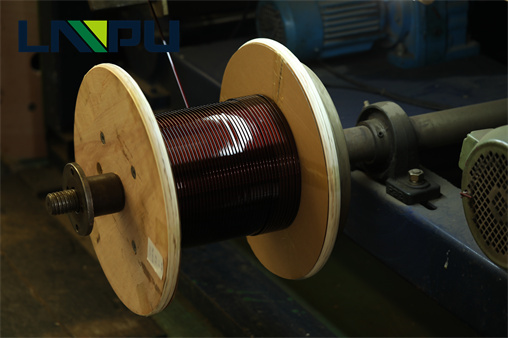

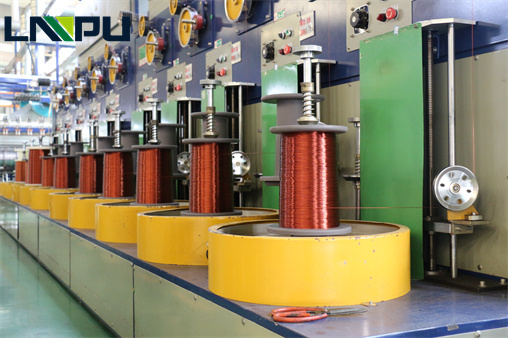

Welcome to see the enameled aluminum wire in Lanpu.