Home » enameled aluminum wire » Aluminum Wire Rod Manufacture For Electrical Purposes Aluminum Foils

Content

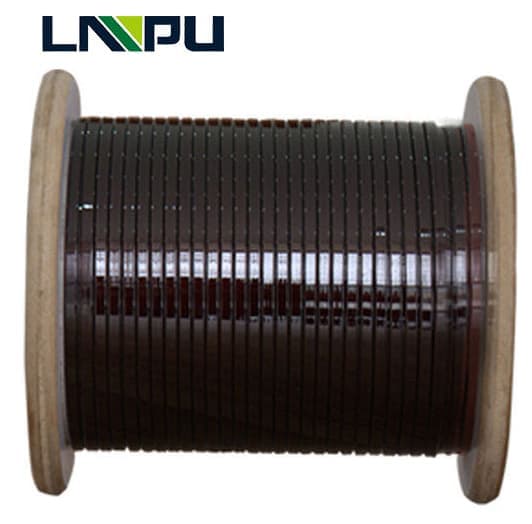

Tolerance on Thickness and Width

| Alloy-Temper | 1060-0 | ||||

| Thickness (mm) | 0.15- 0.4 | 0.4- 0.8 | 0.9- 1.1 | 1.2- 1.6 | 1.8- 3.5 |

| Tolerance | + 0.01 | + 0.015 | + 0.02 | + 0.025 | + 0.03 |

| Width (mm) | < 100 | 100- 200 | 201- 500 | 501- 1250 | > 1250 |

| Tolerance | + 0.1 | + 0.2 | + 0.2 | + 1 | + 2 |

Tolerance on Burr and Collapse

| Thickness (mm) of Strip | Height of Burr (mm) | Height of Collapsed Side (mm) |

| < 0.2 | 0.01 | > 0.05-0.1 |

| 0.2-1.0 | 0.015 | |

| 1.1-1.5 | 0.02 | |

| > 1.6 | 0.03 |

Specification

| Alloy type | 1060-0 | ||||||||

| Chemical Proportion (%) |

Si | Fe | Cu | Mn | Mg | Ni | Zn | Ti | Al |

| 0.057 | 0.24 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.022 | 99.64 | |

| Tensile Strength | 76Mpa | ||||||||

| Elongation (%) | 34 | ||||||||

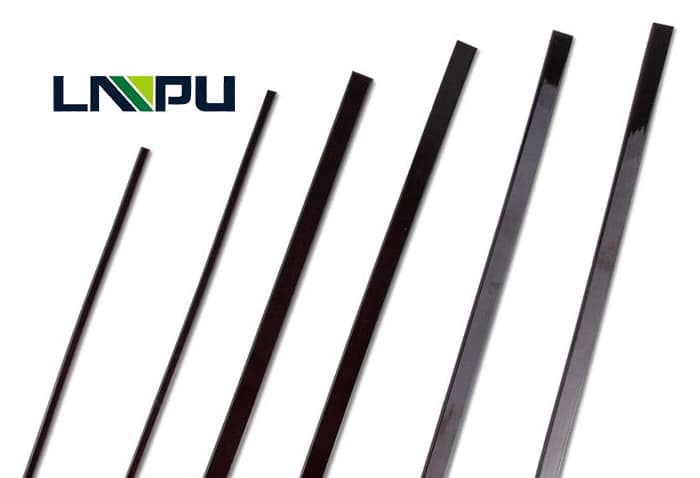

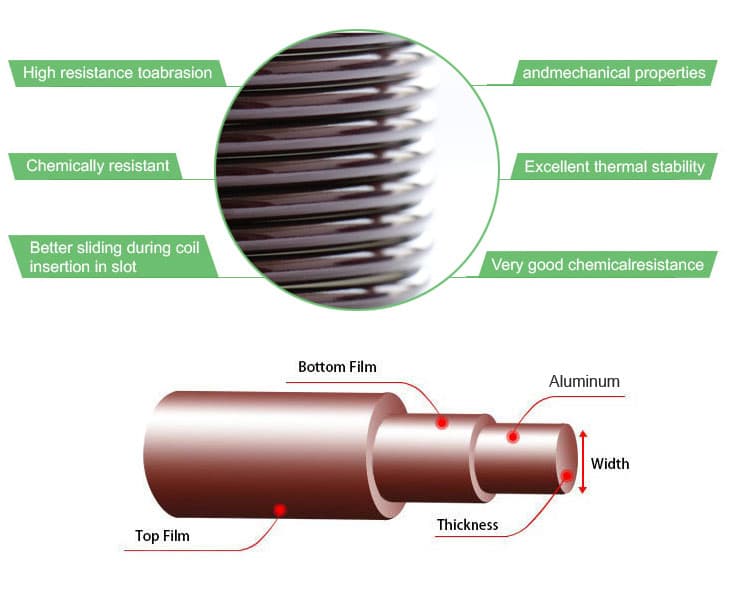

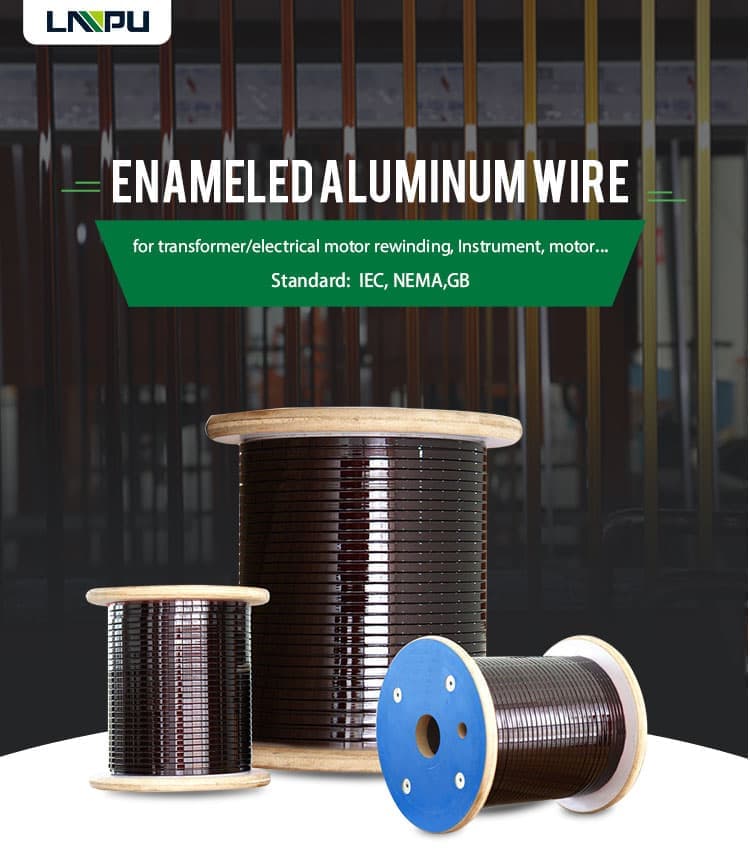

Application

Cable/ Fiber optic cable/ Transformers/ Heater/ Building/ Aerospace/ Automobile industry/ other fields

Go to see the aluminum foil in Lanpu.

Inquiry

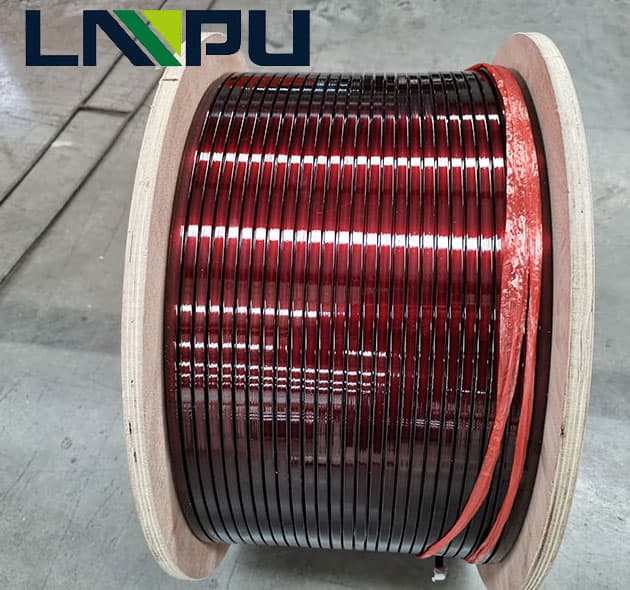

More enameled aluminum wire