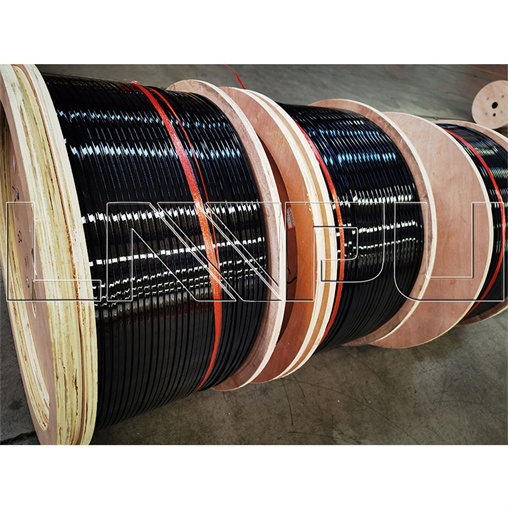

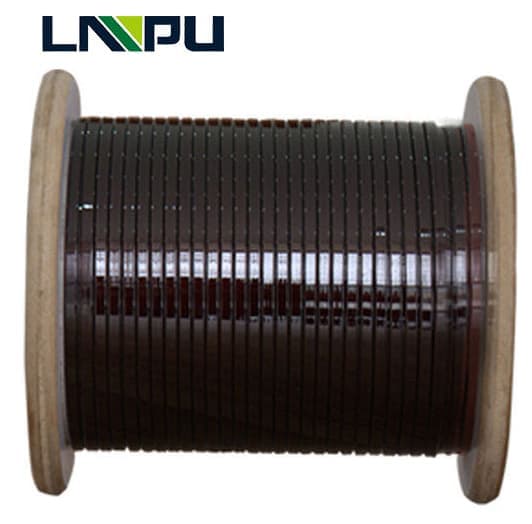

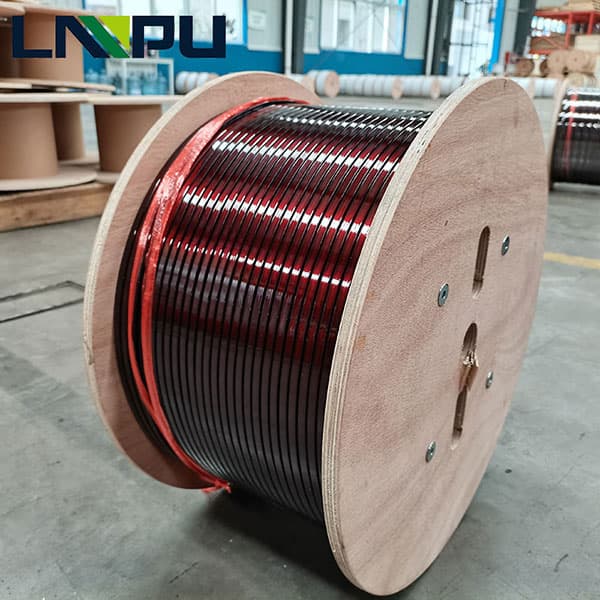

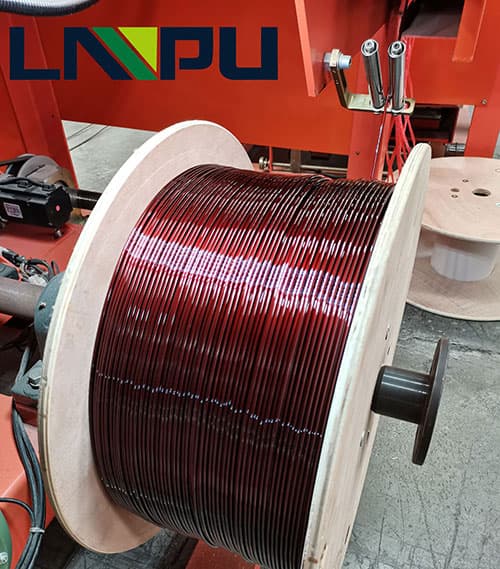

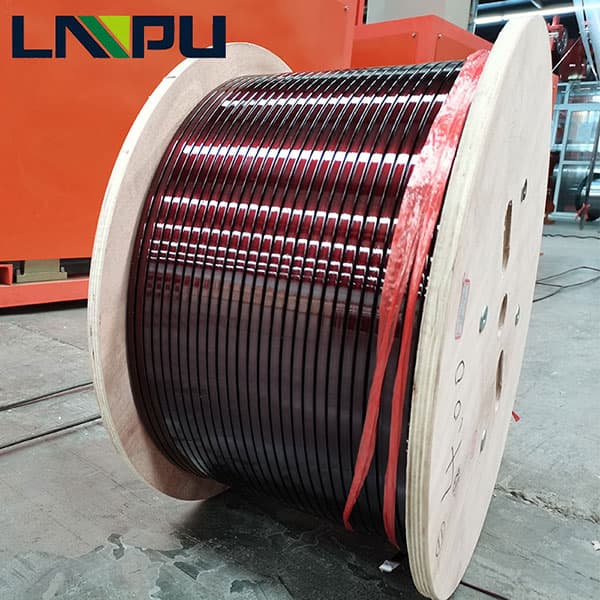

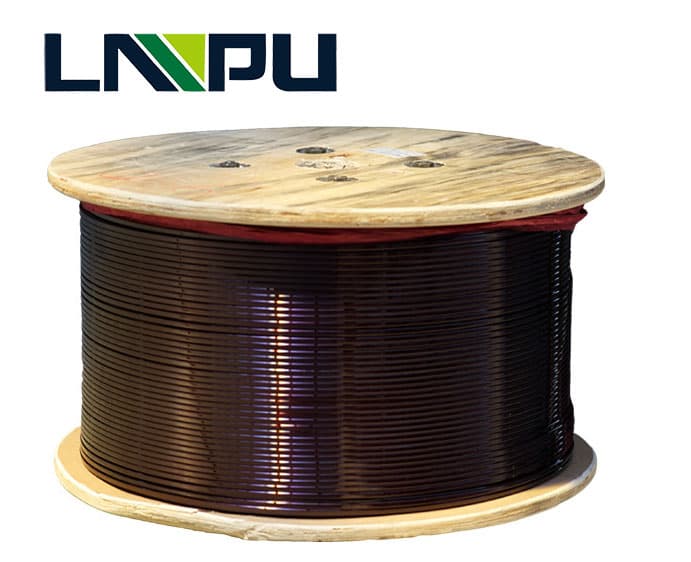

Aluminium Winding Wire

The winding wire is a conductive metal wire with insulation layer, used forwinding a coil or winding in electrical products , which’s usage is to produce the magnetic field by current, or cutting lines to generate theinduction current, conversion between electricity and magnetism, so it is also called electromagnetic wire(magnet wire) .

Classification:

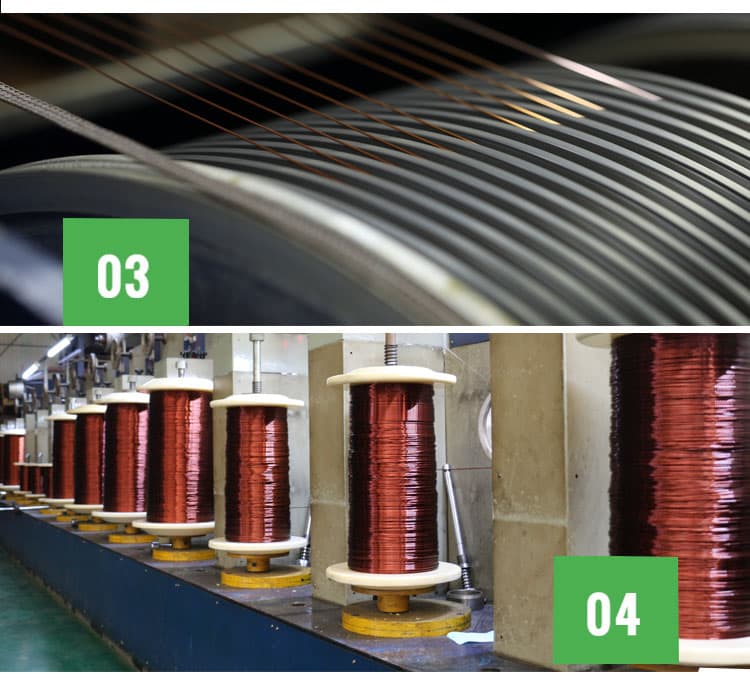

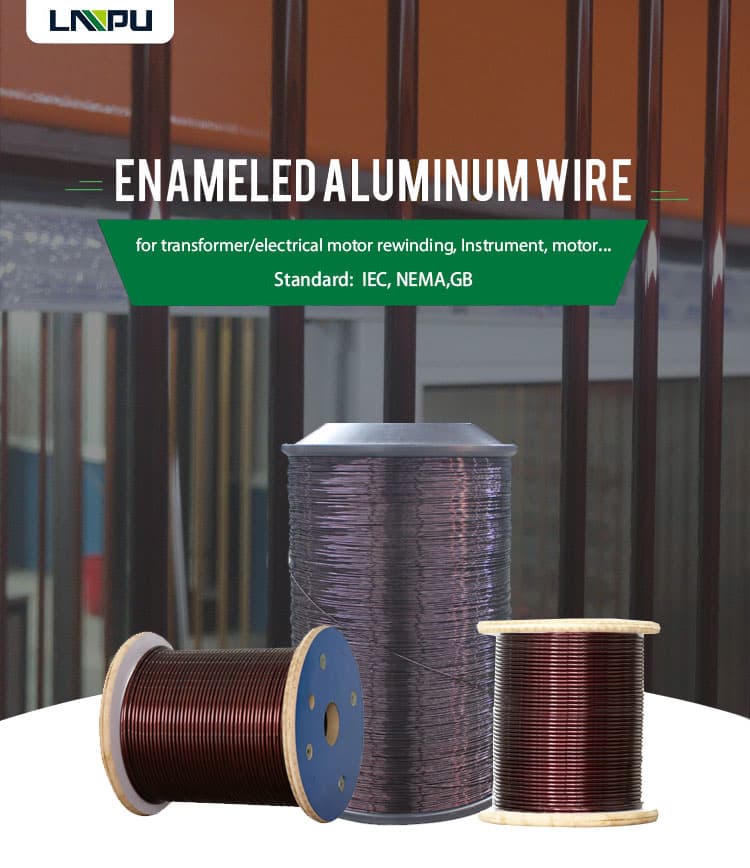

According to the conductor material can be divided into: copper wire, aluminum wire, alloy wire.

According to the insulation materials can be divided into: enameled wire, wrapped wire, inorganic insulated wire.

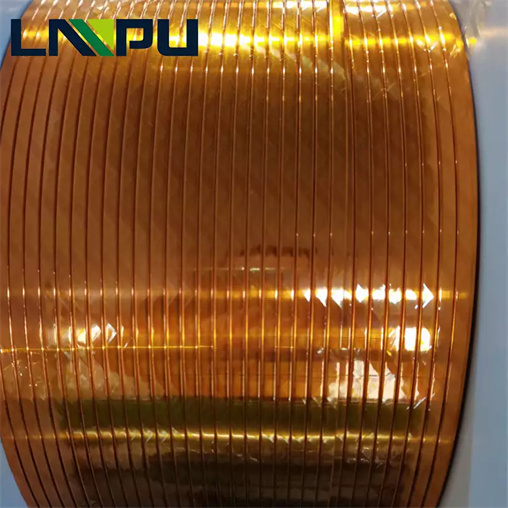

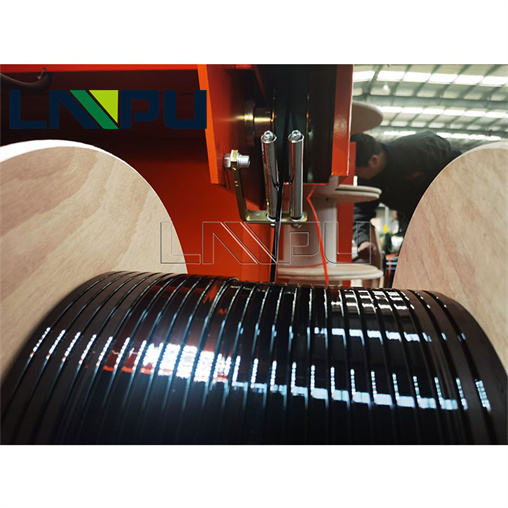

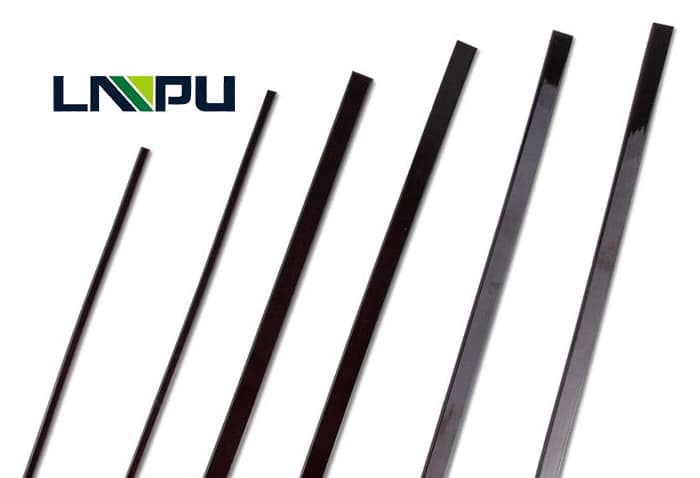

According to the conductor shape can be divided into: round, flat, special-shaped wire.

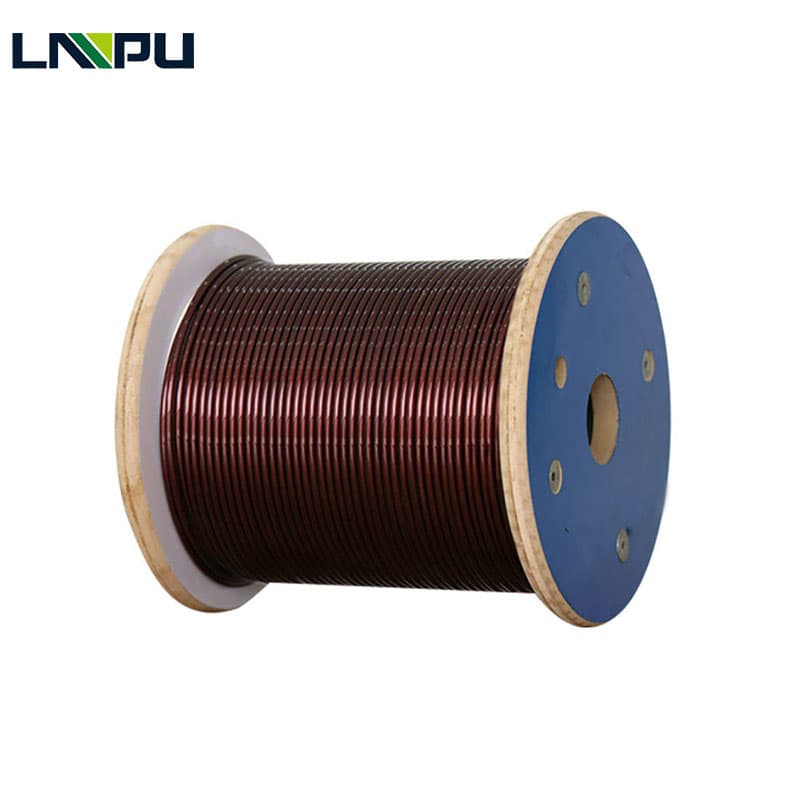

The electromagnetic wire (winding wire) refers to the insulated wire used as the winding or the original in the motor, the electrical appliance and the electrical instrument. There are two kinds of wires in common electromagnetic wires: round wire and flat wire. At present, copper wire and aluminum wire are mostly used. Because of the insulating material is covered on the outside the conductor, the electromagnetic wires have different heat resistance grades.

The commonly used electromagnetic wireis divided in two Classification:enameled wire and wrapped wire:

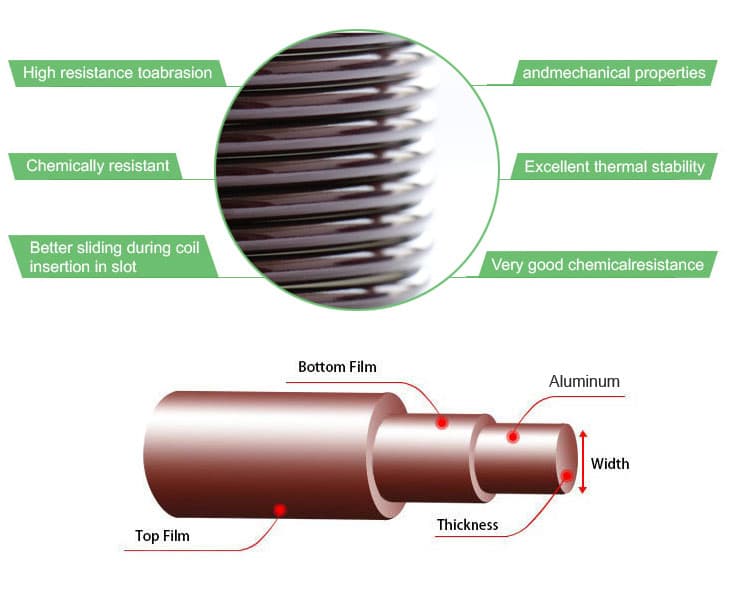

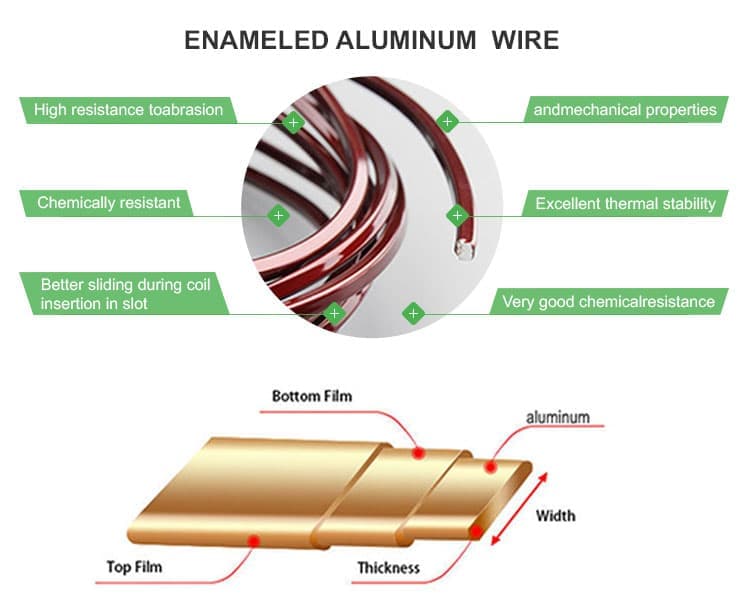

1) enameled wire. The insulating layer of enameled wire is the paint film, which is widely used in small and medium motors and micro motors, dry type transformers and other electrical products.

2) wrapped wire. The wrapped wires are tightly wrapped around the conducting wire core with glass wires, insulating paper or synthetic resin film, and also it can wind the insulating layer on the outside of fibreglass wire