Advantages of hydrogen-oxygen flame enameled wire welding machine

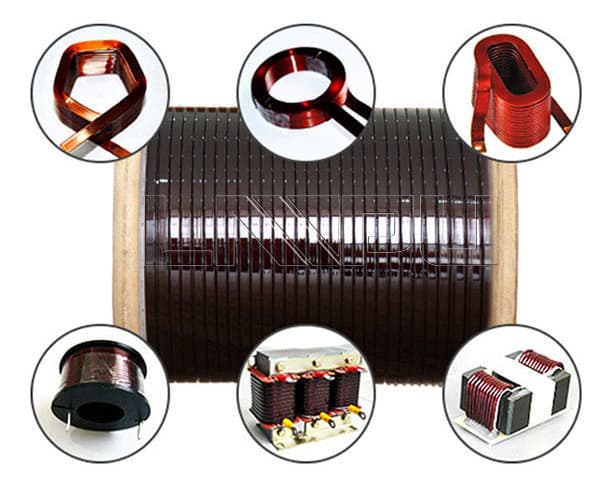

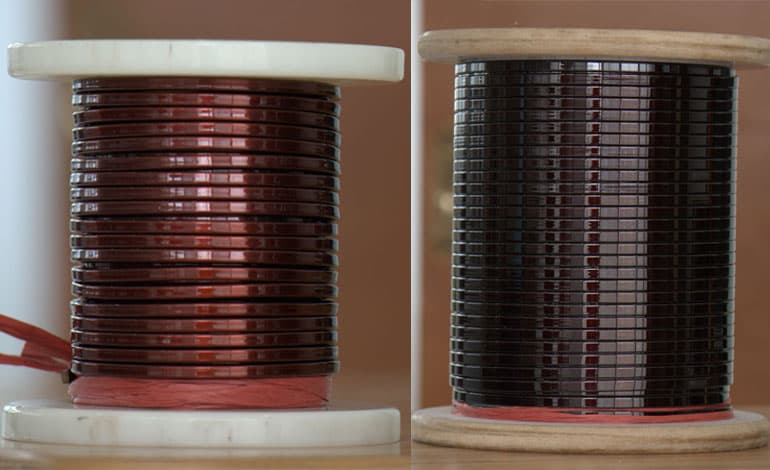

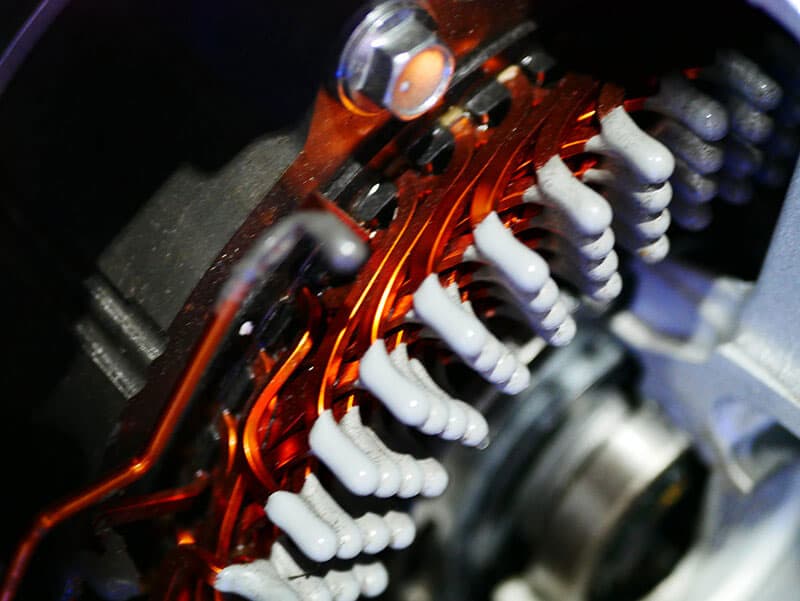

Use a hydrogen-oxygen flame welding machine to weld the coil lead wires of electronic devices such as motors, motors, and transformers.

working principle:

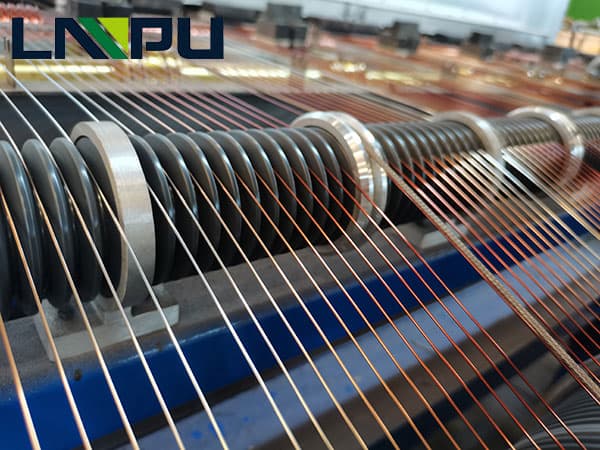

Water is composed of hydrogen and oxygen. In a specific electrolytic cell, water can be decomposed into hydrogen ions and hydroxide ions. The hydrogen ions move to the cathode to generate hydrogen gas, and the hydroxide ions move to the anode to generate oxygen. Hydrogen is a fuel. Oxygen can be used to support combustion. It can be ignited by a specific hydrogen-oxygen flame gun to form a hydrogen-oxygen flame, which can quickly weld the enameled wire.

Features of hydrogen-oxygen flame enameled wire welding machine:

1. Convenience: During the working process, the hydrogen-oxygen flame enameled wire welding machine uses only water and electricity to generate flames for welding operations, without the need for additional gas cylinders, so it is easy to operate. Compared with traditional enameled wire welding, there is no need to remove paint, and because the flame temperature is high, the excess leads can be burned directly, so as to maintain the flatness of the fusion part.

2. Safety: The hydrogen-oxygen flame enameled wire welding machine is ready for use and does not store gas, which avoids the risk of gas cylinder explosion.

3. High efficiency: The flame temperature of the hydrogen-oxygen flame enameled wire welding machine can reach 2800 degrees, which is higher than the temperature of other gases and has a fine flame, which is convenient for precise and efficient operation.

4. Energy saving: The hydrogen-oxygen flame enameled wire welding machine only uses a small amount of water and electricity, and the cost of use is more than 40% less than that of gas cylinders.

With the increasing use of fossil fuels, greenhouse gas emissions are increasing, and the global climate is abnormally intensified. Water welders that meet the energy-saving emission reduction standards advocated now have been applied to more and more industrial processes. Hydrogen-oxygen flame enameled wire welders fully comply with zero emission standards and produce zero harmful gases.