Advantages Of Enameled Aluminum Wire Compared To Enameled Copper Wire

Enameled Aluminum Wire Compared To Enameled Copper Wire have some advantages

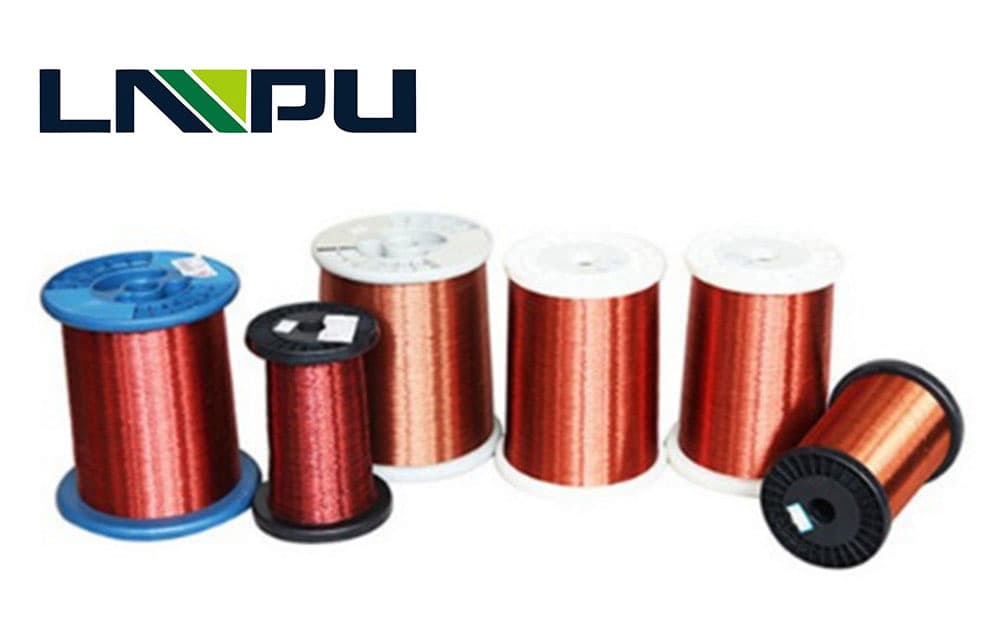

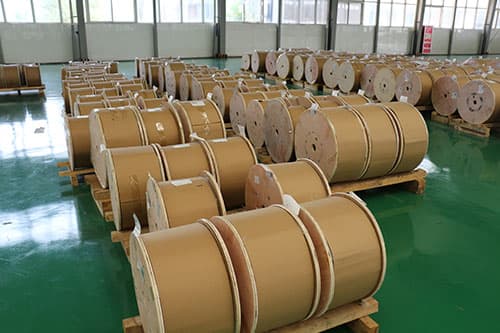

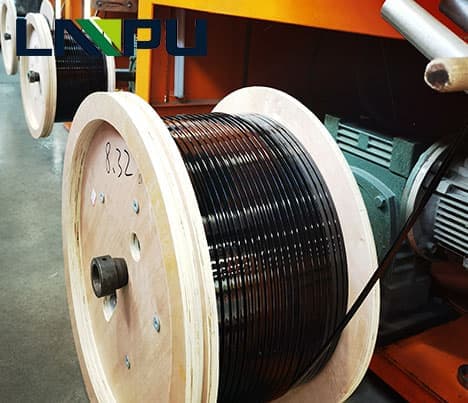

Aluminum /Copper Wire/foils

Dimension:0.2–10.0mm,

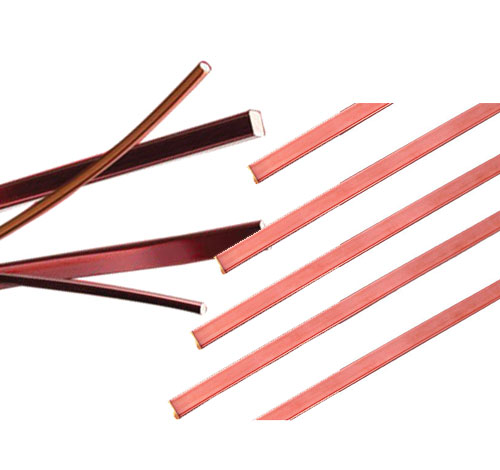

Rectangular: A> 0.8–8mm, B> 2-22.5mm

Square: 0.4*0.4mm–8*8mm

Foils:Thickness:0.2–2.5mm, width:60–1250mm

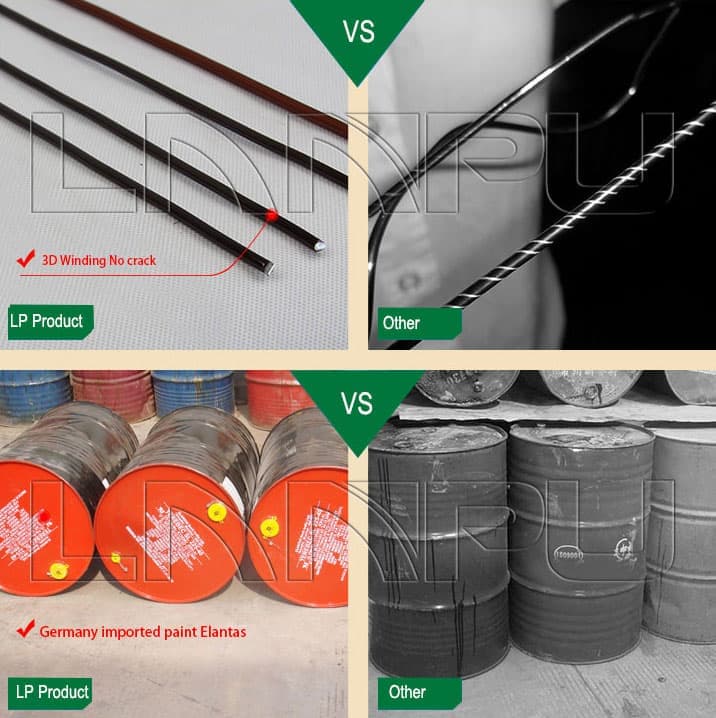

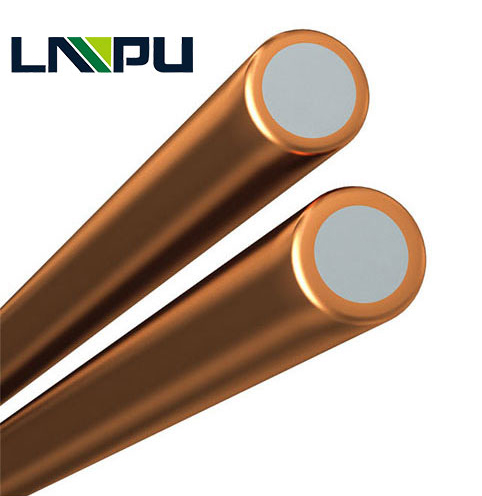

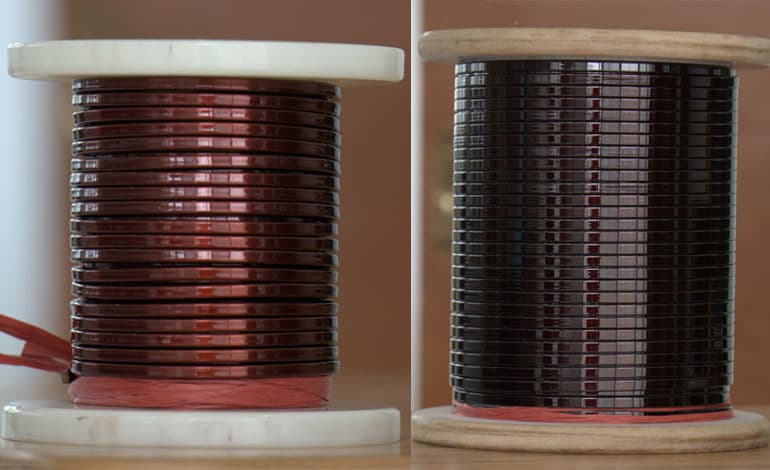

Compared with enameled aluminum wire, enameled aluminum wire has a solid oxide coating on its surface, so it has good insulation effect and long life.

Due to the solid oxide coating insulating layer on its surface, the heat resistance of enameled aluminum wire is better than that of copper wire.

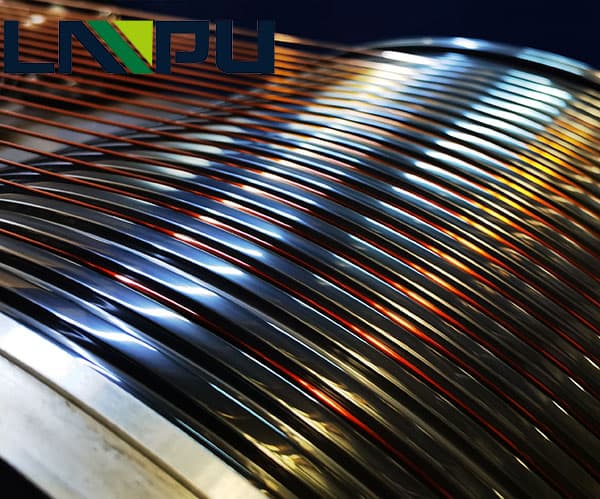

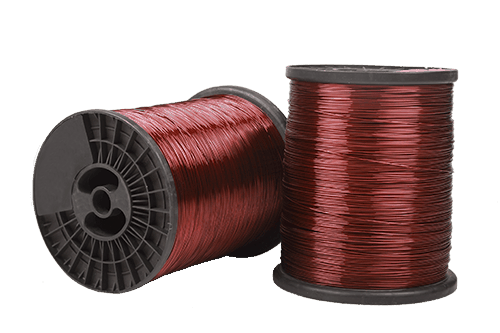

The advantage of using aluminum enameled wire is its light weight. Its weight is only about 1/3 of copper wire. And because aluminum is very cheap compared to aluminum, it can greatly reduce production costs. It is easy to connect to the implant, which can also reduce freight and transportation during the operation.

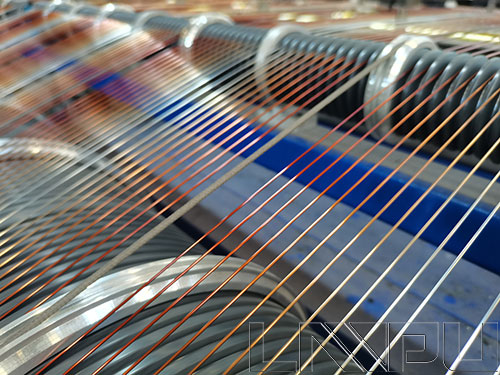

Magnet wires play a vital role in the three fields of energy conversion: electrical to electrical, electrical to machinery, and mechanical to electrical.

Common enameled aluminum wires include round enameled aluminum wires and Rectangular Enameled Aluminum Wire.