Aluminum Magnet Wire

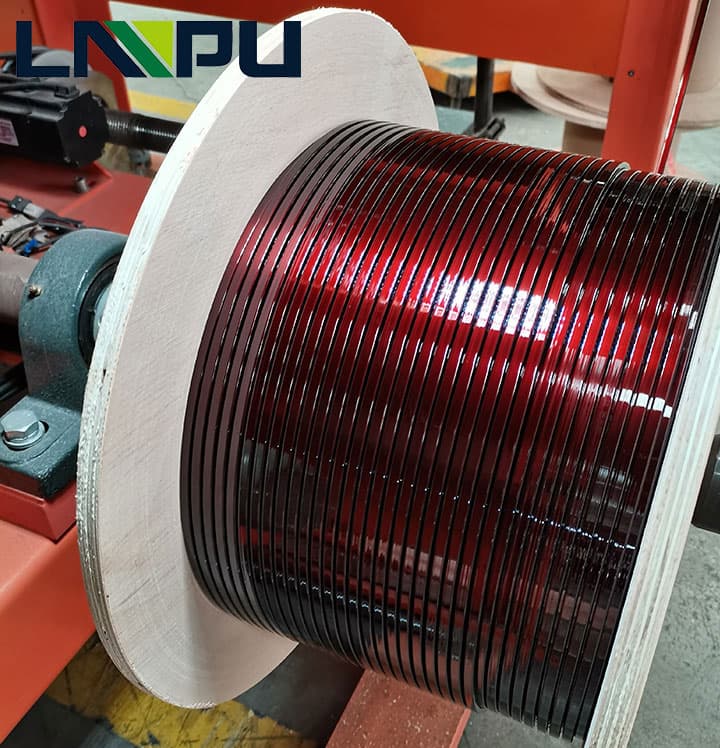

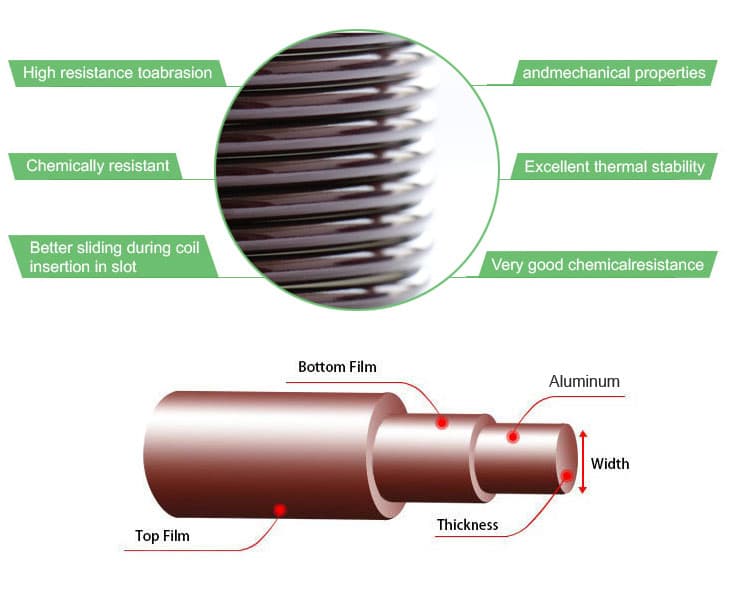

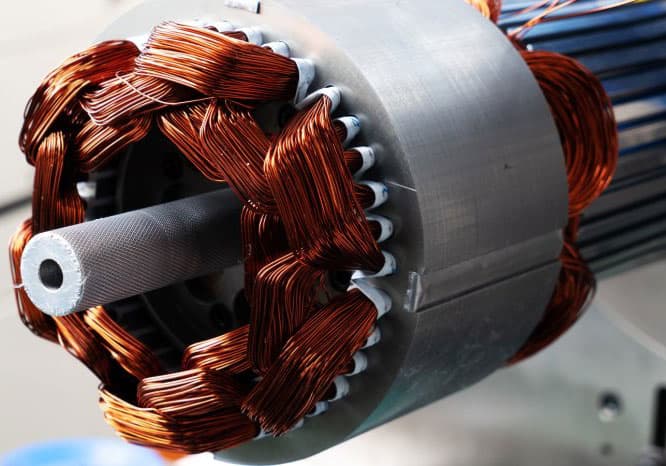

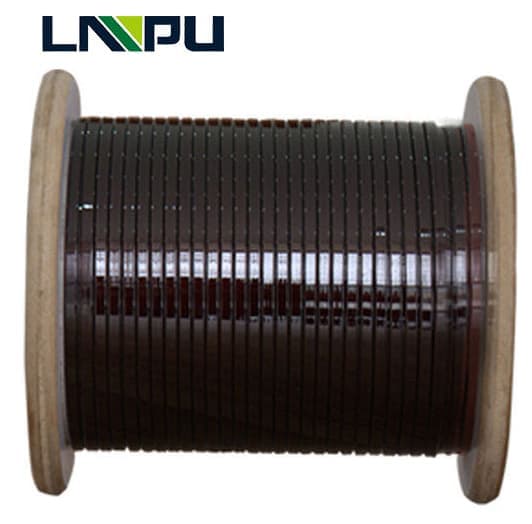

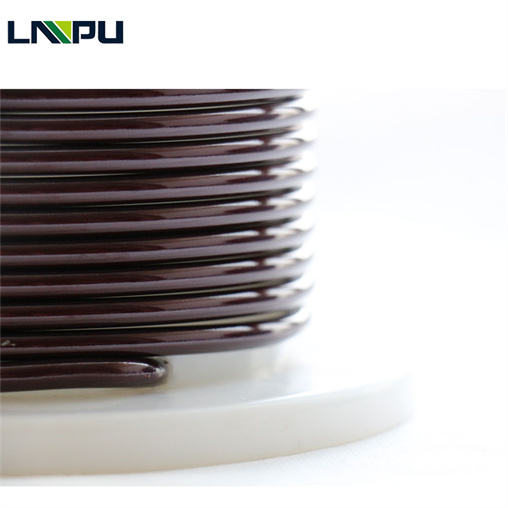

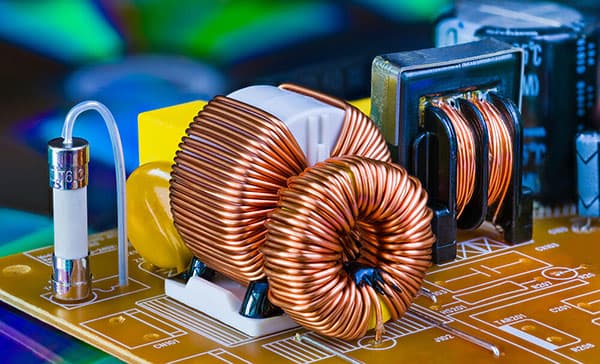

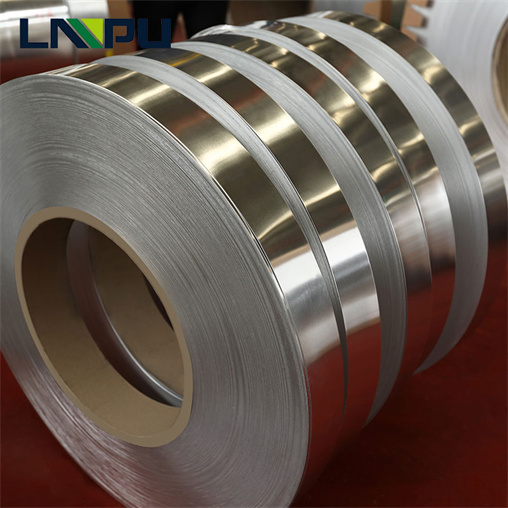

Aluminum Magnet Wire can be divided into round aluminum wire and flat aluminum wire, also includes self-bonding aluminum wire and soldering aluminum wire. and aluminum magnet wire is widely usedfor transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

The aluminium Magnet wire is one of the strongest wires. It is used in many different industries, such as automobiles, electronic equipment, and wires. Compared with copper wire, this type of wire has many advantages. The copper wire has a tendency to rust after it is outside. It is also prone to deterioration when exposed to moisture. For most applications, this makes copper wire a poor choice.

Standard alumina wire is cheap and can be used with most electronic devices. It sometimes wraps around or even wraps around the object. Wires are relatively non-conductive, but it is relatively easy to wrap various objects on the wires. The biggest weakness of aluminum magnet wire is that it cannot provide enough strength to support heavy objects. As a result, the wire will bend significantly before the object receives any strain.

There are two configurations of plastic-coated enameled wire. Magnetic and non-magnetic. Non-magnetic varieties are also available. These wires are commonly used in jewelry applications and other consumer products. They provide flexibility because they can be easily cut by hand to the specific diameter required. As the surface is smooth and non-sticky, the plastic coating provides excellent grip.

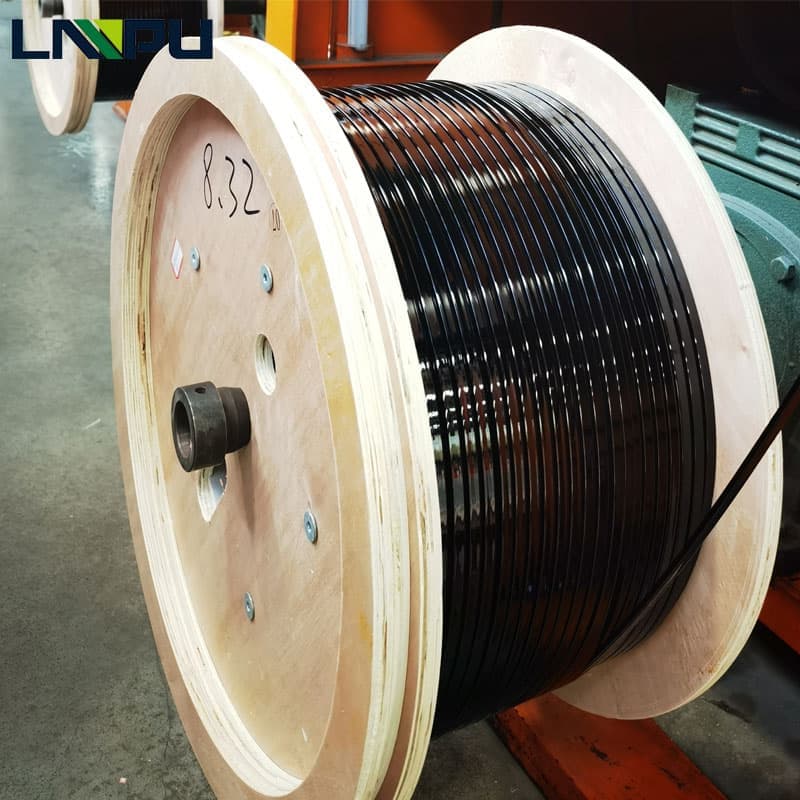

There are three different configurations of insulated wires: polyethylene (PE), galvanized steel, and flat steel. Polyethylene is the most flexible type of aluminum magnet wire. It can provide a tight fit and high strength. Because it is very thin, it also allows dust to collect on the surface. It is not recommended to use these types of wires for electrical applications because of the risk of short circuits and fire.

Flat steel is the most popular and most versatile configuration among insulated wires. Its high strength grade allows it to withstand a lot of weight while maintaining a tight fit. Flat steel is usually used to support cable racks, connectors, and clamps. It is also the most expensive type of aluminum magnet wire.