7 Precautions in the use of enameled wire

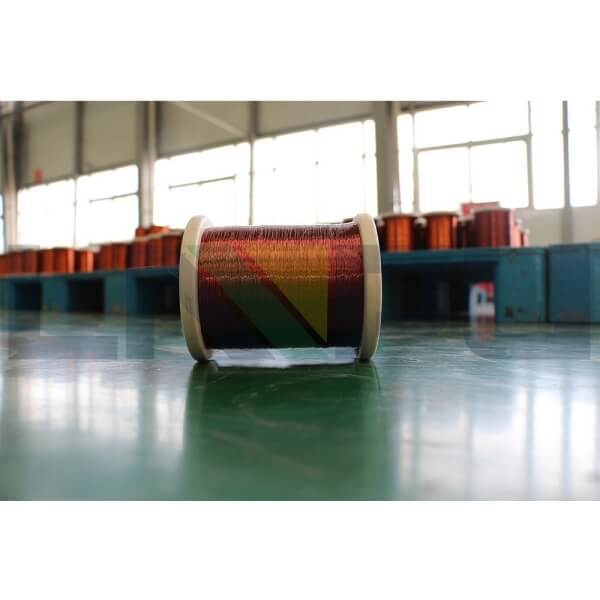

Precautions for storage should be well packaged, should not be placed in a high-humidity warehouse, should not be exposed to direct sunlight, and should not be placed near acids, alkalis and organic solvents.

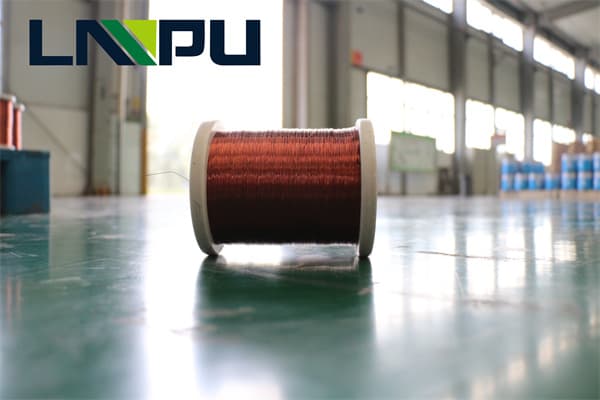

Precautions in the use of enameled wire

1. Precautions for storage should be well packaged, should not be placed in a high-humidity warehouse, should not be exposed to direct sunlight, and should not be placed near acids, alkalis and organic solvents.

2. General precautions The workplace should be dust-free and dry, and the room temperature should be 5¡«30¡æ; the clothing of the operator should be clean, and there should be no oil and dust on the hands; all parts of the machinery used should be checked before the operation, if not If it is normal, it should be repaired. Check the name, type and specification of the enameled wire used.

3. Precautions when winding the coil. Check the size and shape of the metal or wooden mold used, and must not have sharp corners and raised parts; when the enameled wire is discharged from the spool, prevent the enameled wire from being damaged due to disordered wires and kinks; In the case of wire, the tension should be adjusted to avoid excessive elongation of the enameled wire. Hard objects such as metal should not touch the surface of the enameled wire; when the coil is wound at high speed with an automatic winding machine, due to the high tension, there are more opportunities for contact with the metal surface. Special attention is required; when it is necessary to strike the coil, it is forbidden to use a hammer, and it is better to use a wooden or plastic hammer.

4. Precautions during forming When the coil is formed, the enameled wire is subject to bending, torsion, tension, impact and other machinery

Stress, so it is necessary to heat treatment after molding. However, if the heating temperature of the polyester enameled wire reaches 150¡ãC or higher, it will be affected by thermal shock, so care must be taken.

5. Precautions after forming When the formed coil is transported or processed for other purposes, care should be taken not to deform the coil or damage the paint film. Therefore, the arrangement and placement of the coils should be considered. In addition, dust, especially metal powder and moisture should be avoided during storage.

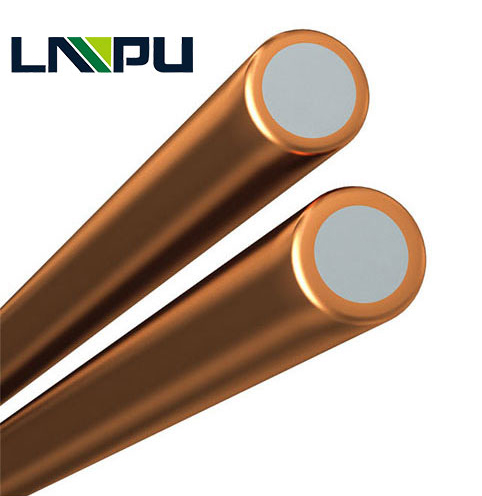

6. Precautions when assembling the coil When rubbing with a small bamboo chip, beating or bending with a wooden hammer, pay special attention to whether there are sharp corners or protruding parts on the iron core, and prevent damage to the paint film due to friction at the exit of the notch. Acetal and heat-resistant enameled wires have good abrasion resistance, while polyester is 60% of acetal, and polyurethane and oily enameled wires are inferior. Taking these factors into account, the core should not have sharp corners or protruding parts and bad exits. , Should not cause excessive friction on the enameled wire.

7. Precautions for dipping treatment To improve the mechanical and electrical properties of the coil after forming, and to suppress the aging of the paint film under the conditions of high temperature and humidity, the dipping treatment has a better effect. The choice of dipping varnish should take into account that the immersed enameled wire is not corroded by it, and the conditions of the dipping treatment should be consistent with the characteristics of the enameled wire, and it is even necessary to carefully consider the so-called compatibility issue.