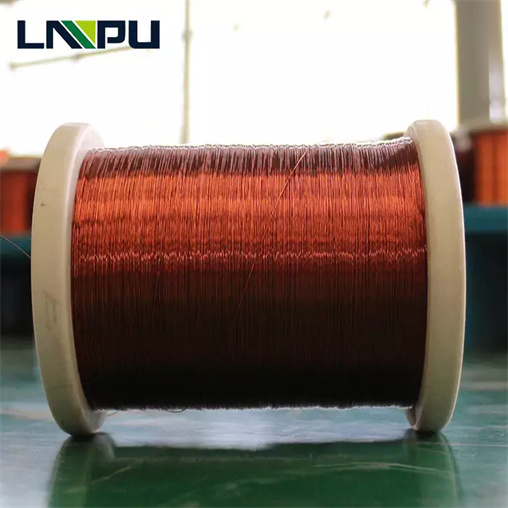

24swg motor polyester enameled round copper wire winding copper enamel wire

Product Name£º24swg motor winding copper wire

Type: round and rectangular copper wire

Round Dimension:24swg

Conductor Material£ºCopper

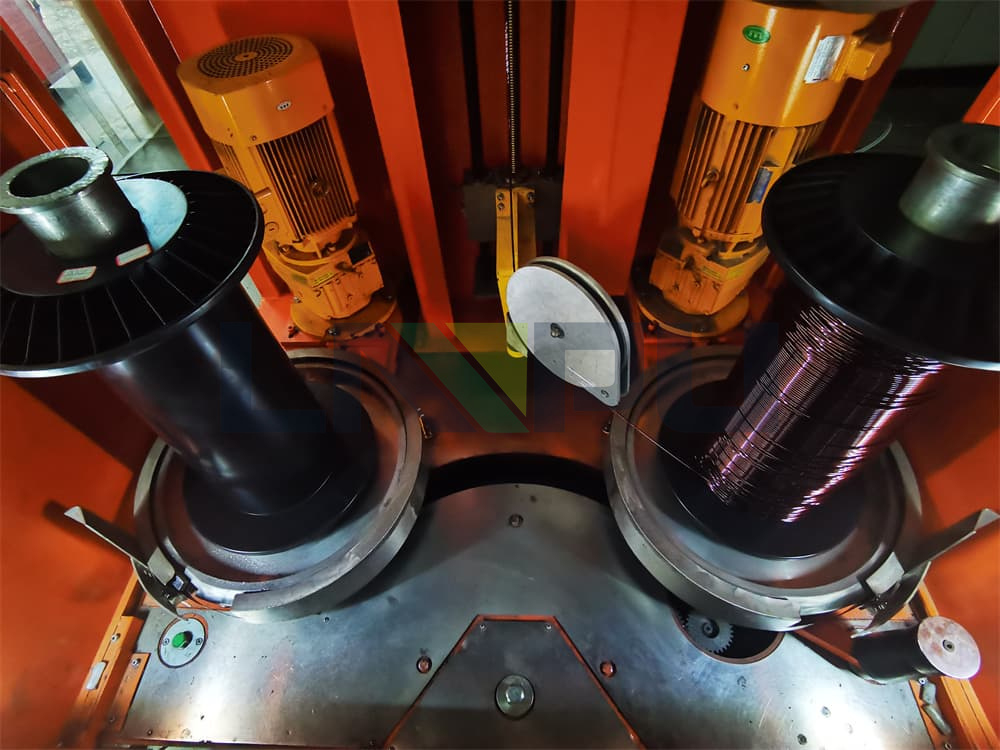

Application£ºused for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

Certificate£ºUL,RoHS

Insulation Materilas£ºUEW, QZ, QZY, EIW, etc.

Thermal Class:105 ¡ãC, 120 ¡ãC, 140 ¡ãC, 155 ¡ãC, 180 ¡ãC, 200 ¡ãC, 220 ¡ãC, 240 ¡ãC

Advantages and Disadvantages of Enameled Copper Wire

(1) Low resistivity: The electrical resistance of the enameled copper cable is about 1.68 times higher than that of the copper wire cable. click here for more details.

(2) Good ductility: the elongation rate of copper alloy is 20~40%, the elongation rate of copper for electricians is above 30%, and the aluminum alloy is only 18%.

(3) High strength: Allowable stress at normal temperature, copper is 7~28% higher than aluminum. Especially the stress at high temperature, the difference between the two is far.

(4) Anti-fatigue: aluminum is easily bent and broken, and copper is not easy. In terms of elasticity, copper is also about 1.7 to 1.8 times higher than aluminum.

(5) Good stability, corrosion resistance: copper wire is resistant to oxidation and corrosion, and aluminum wire is susceptible to oxidation and corrosion.

(6) Large current carrying capacity: Due to the low resistivity, the enameled copper wire cable of the same section is 30%-50% higher than the allowable current capacity (the maximum current that can be passed) of the aluminum wire cable, especially the household appliances are more and more The home is basically made of copper wire.

(7) Low voltage loss: Since the resistivity of the copper wire cable is low, the same current flows in the same section. The copper cable has a small voltage drop. Therefore, the same transmission distance can guarantee higher voltage quality; or, under the allowable voltage drop condition, the copper cable power transmission reaches a long distance, that is, the power supply coverage area is large, which is conducive to network planning and reduction. The number of power points set.

(8) Low heat generation: Under the same current, the copper wire of the same section has a much smaller heat generation than the aluminum wire cable, making the operation safer.

(9) Low electrical loss: Since the resistivity of copper is low, the power loss of the copper cable is low compared to the aluminum cable, which is obvious. This is conducive to improving power generation efficiency and protecting the environment.

(10) Anti-oxidation and corrosion resistance: The connector of the Enameled Copper Wire cable has stable performance and will not cause accidents due to oxidation. When the joint of the aluminum wire cable is unstable, the contact resistance is increased due to oxidation, and an accident occurs due to heat generation. Therefore, the accident rate is much larger than that of copper wire. Especially in the place where some copper wires and aluminum wires are docked, there is a problem when the connection time is not long. Therefore, the copper wire and the aluminum wire must be connected in strict accordance with the requirements.