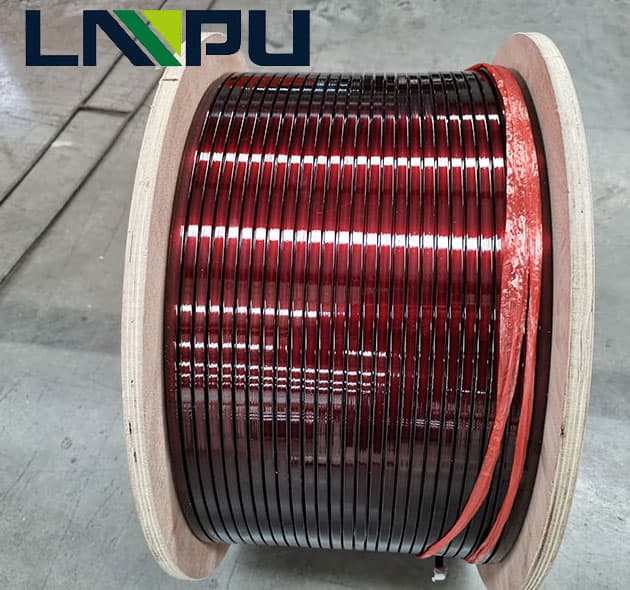

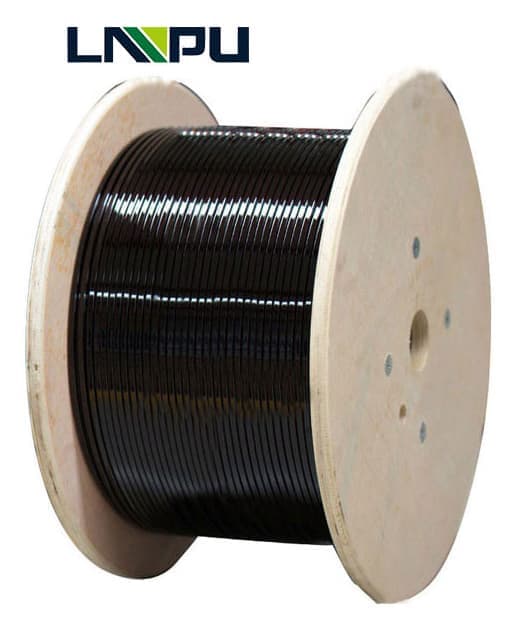

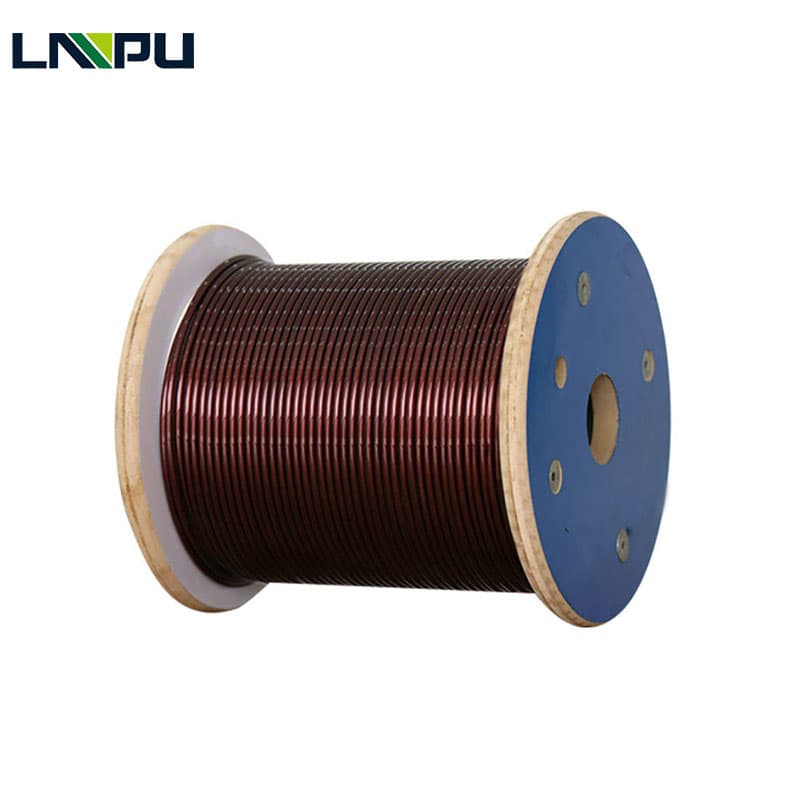

130 155 180 Degree 7 8 9 10 11 12 13 Awg Aluminum Magnet Wire

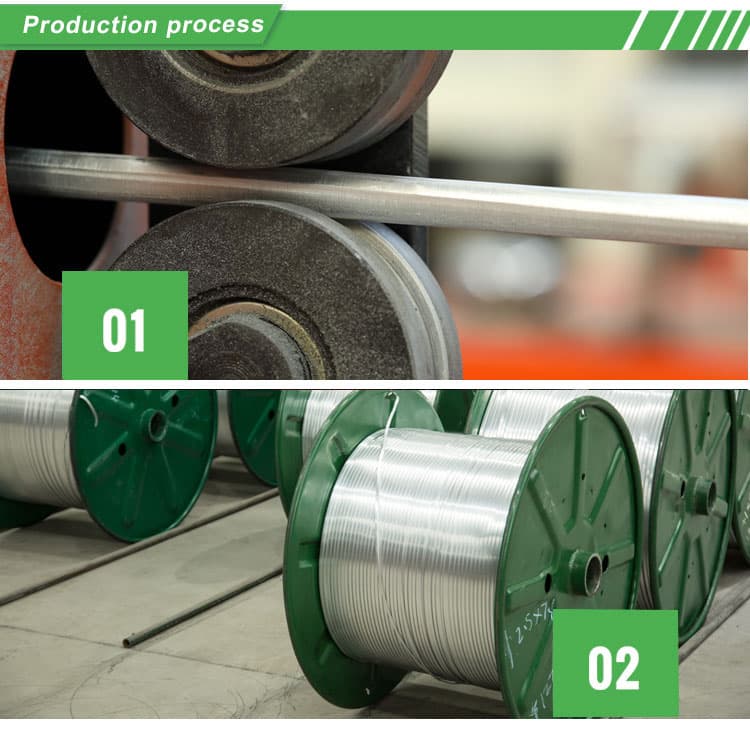

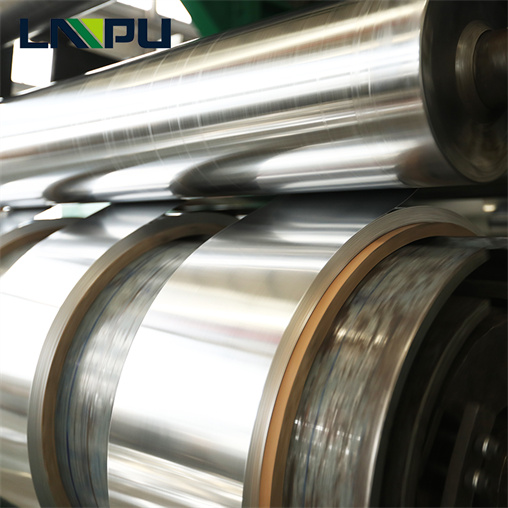

Magnet wire, also known as winding wire, can be classified according to its basic structure, conductive core and electrical insulation layer. Generally, it is divided into enameled wire, winding wire, enameled winding wire and inorganic insulated wire according to the insulating material and manufacturing method used in the electrical insulating layer. 130 155 180 Degree 7 8 9 10 11 12 13 Awg Aluminum Magnet Wire is hot products made by LP Industry.

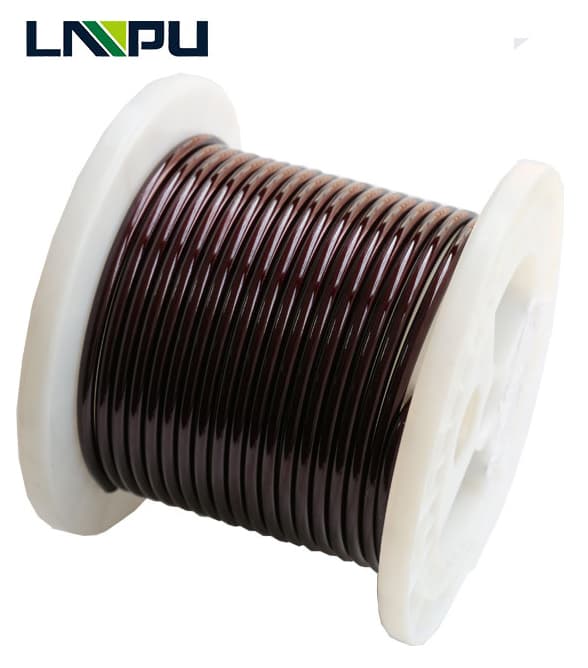

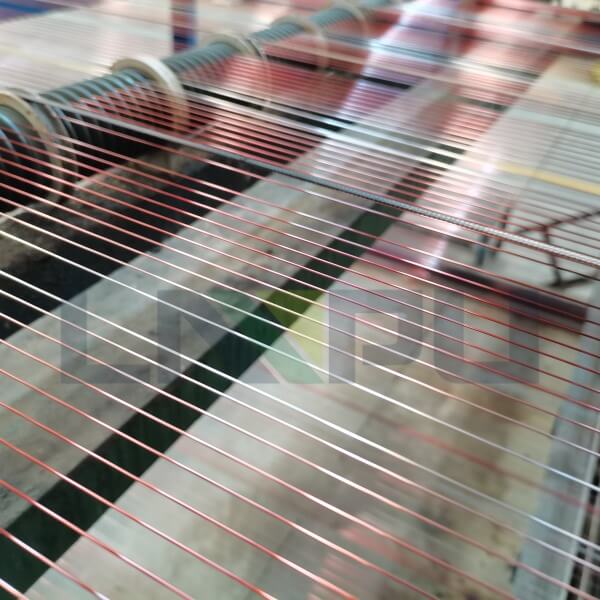

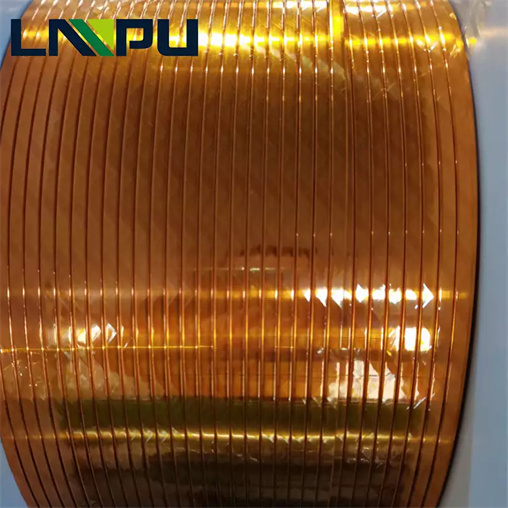

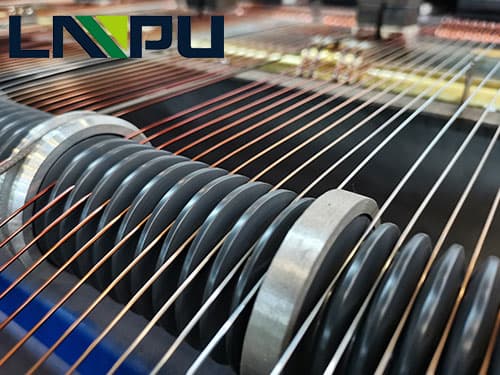

Enameled wire: coated with a corresponding lacquer solution on the outside of the conductor, and then made by solvent evaporation and curing and cooling of the lacquer film. Enameled wire can be divided into oil paint, acetal paint, polyester enameled wire, polyesterimide enameled wire, polyamideimide enameled wire, polyimide enameled wire, polyurethane enameled wire, etc. according to the insulating paint used. Sometimes it is also classified according to the particularity of its use, such as self-adhesive enameled wire, refrigerant-resistant enameled wire, self-lubricating enameled wire, direct drought enameled wire, etc.

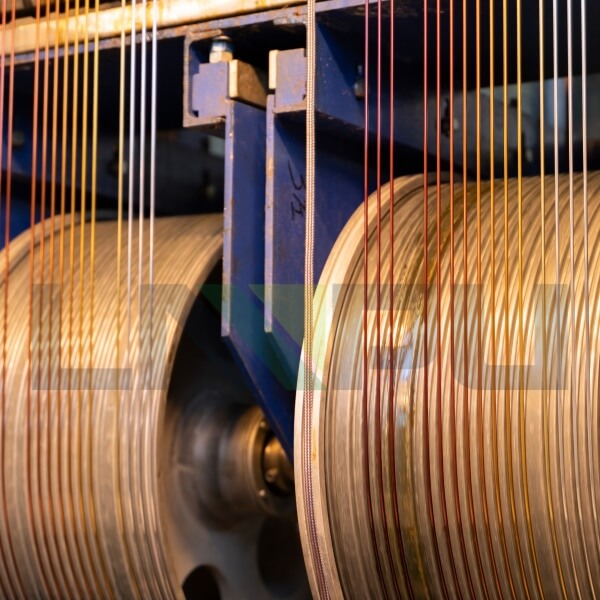

The earliest enameled wire was oily enameled wire, made of tung oil. The paint film has poor abrasion resistance and cannot be directly used to make motor coils and windings. It needs to be covered with cotton yarn when used. Later, polyvinyl formal enameled wire came out, and its mechanical properties improved greatly. It can be directly used in motor windings and is called high-strength enameled wire.

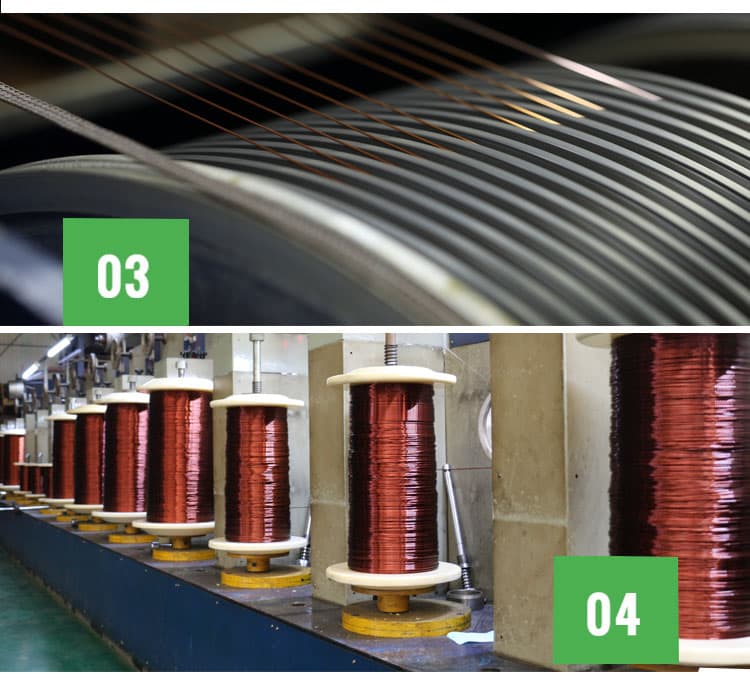

With the development of shopping malls and technology, self-adhesive enameled wires have appeared, which can obtain coils with better integrity without dipping and baking. In addition, in order to prevent the trouble of removing the paint film during welding, the direct-welding enameled wire was developed. The film can fall by itself in the high-temperature tin bath to make the copper wire easy to weld, which greatly improves the work efficiency of the low-level industry! Adhesive wire was one of the most promising types of enameled wire work at that time.

In addition, composite enameled wires have appeared. The inner and outer paint films are made of different polymer materials, such as polyesterimide/polyamideimide enameled wire.

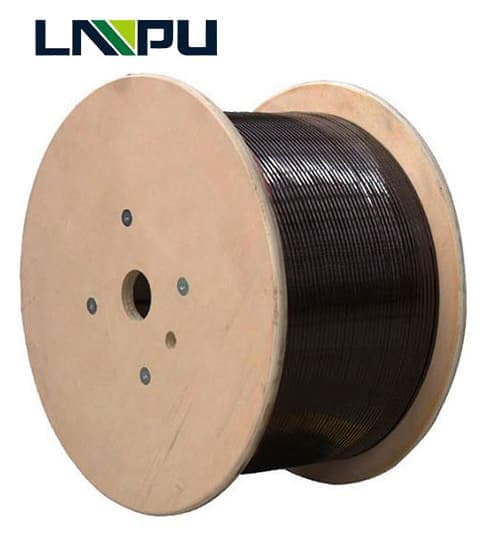

Wrapped wire: It is an important type of winding wire. The cotton yarn and silk used in the early stage are called yarn-covered wire and silk-covered wire, which were once used in motors and electrical appliances. Due to the large insulation thickness and low heat resistance, most of them have been replaced by enameled wires. At that time it was only used as a high-frequency winding wire. In the large and medium-sized standard winding wires, when the heat resistance level is higher and the mechanical strength is higher, glass fiber covered wires are also used, and they are made with appropriate adhesive paint.