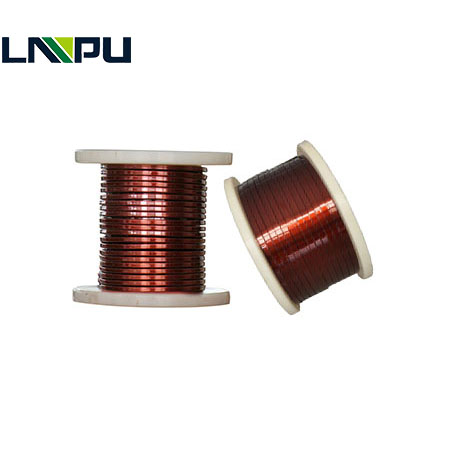

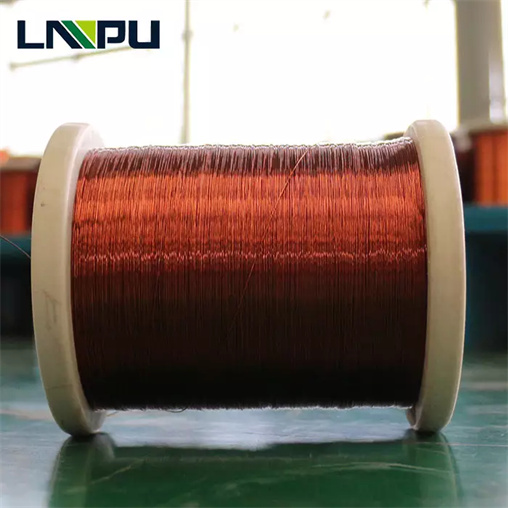

0.025-4.5mm Super Enameled Copper Wire In Phuket With Factory Price

0.025-4.5mm Super Enameled Copper Wire In Phuket With Factory Price

Mechanical properties: including elongation, rebound angle, softness and adhesion, scratching, tensile strength and other items.

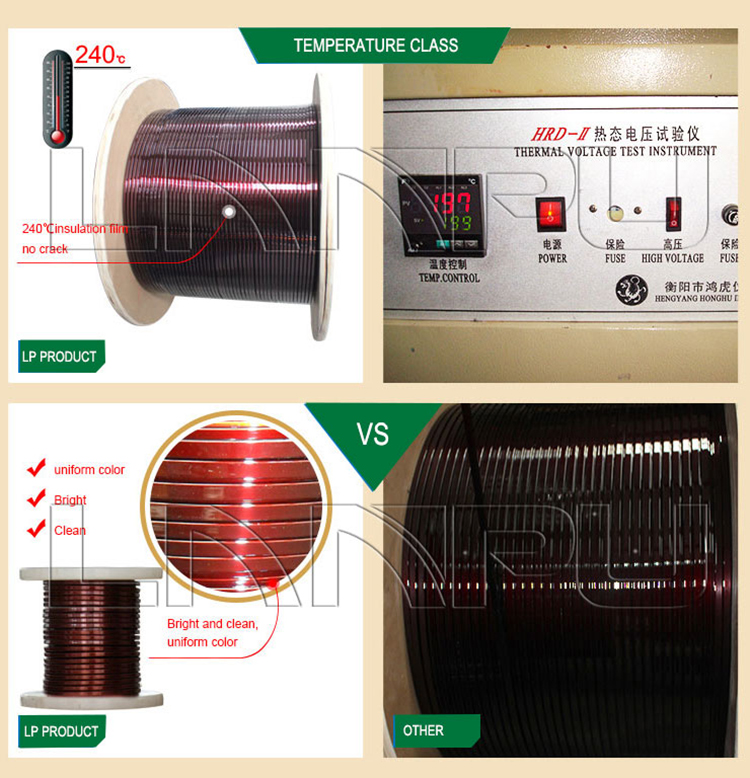

Heat resistance: including thermal shock and softening breakdown test.

Electrical properties include: breakdown voltage, paint film continuity and DC resistance test.

Chemical resistance includes solvent resistance and direct solderability.

1 mechanical properties

1.1 The elongation rate reflects the plastic degeneration of the material, which is used to assess the ductility of the enameled wire.

1.2 The rebound angle and softness reflect the elastic deformation of the material, which is used to assess the softness of the enameled wire.

The elongation, rebound angle and softness reflect the quality of the copper material and the annealing degree of the enameled wire. The main factors that affect enameled wire elongation and rebound angle are (1) wire quality; (2) influence of external force; (3) degree of annealing.

1.3 The toughness of the paint film includes winding and stretching, that is, the allowable amount of tensile deformation that the paint film deforms without breaking when the conductor is stretched.

1.4 The adhesion of paint film includes snap-off and peeling, which mainly examines the adhesion ability of paint film to conductor.

1.5 The scratch resistance test of the paint film of the enameled wire reflects the strength of the paint film against mechanical scratches.

2. Heat resistance

2.1 The thermal shock of enameled wire is the ability of the paint film of the enameled wire to withstand heat under mechanical stress.

Factors affecting thermal shock: paint, copper wire, enameled process.

2.3 The softening and breakdown performance of the enameled wire is a measure of the ability of the enameled wire’s paint film to withstand thermal deformation under mechanical force, that is, the ability of the pressured paint film to plasticize and soften at high temperatures. The heat-resistant softening and breakdown performance of the enameled wire paint film is determined by the molecular structure of the paint film and the force between the molecular chains.

3. Electrical properties include

3.1 Breakdown voltage refers to the ability of the enameled wire paint film to withstand the voltage load. The main factors affecting the breakdown voltage: (1) the thickness of the paint film; (2) the roundness of the paint film; (3) the degree of curing; (4) the external impurities in the paint film.

3.2 Paint film continuity test is also called pinhole test, its main influencing factors: (1) raw materials; (2) operation process; (3) equipment.

3.3 DC resistance refers to the measured resistance value per unit length. Its main influencing factors: (1) the degree of annealing; (2) the enameled equipment.

4. Chemical resistance

4.1 Solvent resistance. Generally, the enameled wire undergoes a dipping process after being wound into a coil. The solvent in the dipping paint has a different degree of swelling effect on the paint film, especially at higher temperatures. The chemical resistance of the enameled wire paint film is mainly determined by the characteristics of the paint film itself. Under certain conditions of the paint, the enameling process also has a certain influence on the solvent resistance of the enameled wire.

4.2 The direct welding performance of the enameled wire reflects the ability of the enameled wire to solder during the winding process without removing the paint film. The main factors that affect the solderability are: (1): the influence of the process, (2) the influence of the paint,